梅花公寓| พลัมคอนโด

Plum Central station 是一个 38 层的公寓项目,由 2 座塔楼组成,位于曼谷西北部,靠近 Bang Yai 高架地铁站。该住宅楼将容纳 1,013 套公寓。

该项目一期工程(第一座塔楼)于2015年9月开工,将于2018年3月左右竣工。通过使用“全预制”混凝土技术,使快速施工成为可能。

该项目的业主 Pruksa 正在为该项目运营自己的预制工厂。

对于这个项目,Pruksa 的目标是能够快速为地面以上的所有楼层安装预制板(充当剪力墙)。 Dextra 建议为此使用 Groutec 耦合器。

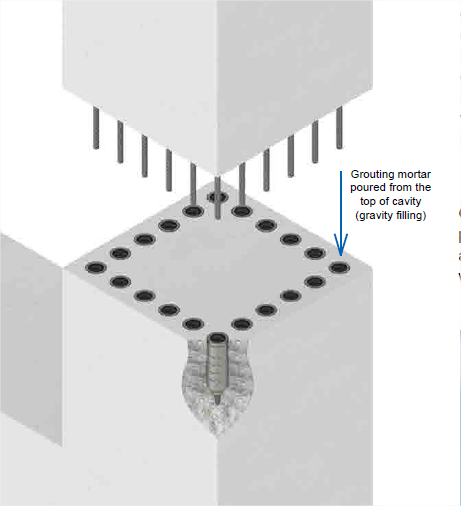

Groutec 连接器,安装在预先用 Bartec 螺纹准备的 Ø25mm 钢筋上。安装在每个预制元件底部的连接器随后被铸造为预制墙板元件的一部分。

在现场将元件提升到上层后,通过注入无收缩砂浆实现与突出钢筋的重新连接。值得注意的是,Dextra 不提供砂浆,而是可以在当地采购,从而节省大量成本。注入灌浆后,每块面板周围的支撑可在 3 天后拆除。

有关 Plum Central Station 和 Groutec 应用的更多信息,请参阅我们的案例研究。