墨尔本地铁:五个新地铁站

墨尔本大都会铁路服务运营着226列六节车厢列车,覆盖998公里的轨道。该地铁拥有15条线路和222个车站,每天为全市超过40万名乘客提供服务。

2017 年,宣布修建一条 9 公里长的隧道和五个新的地下车站,以增加容量并扩大该市郊区的覆盖范围。

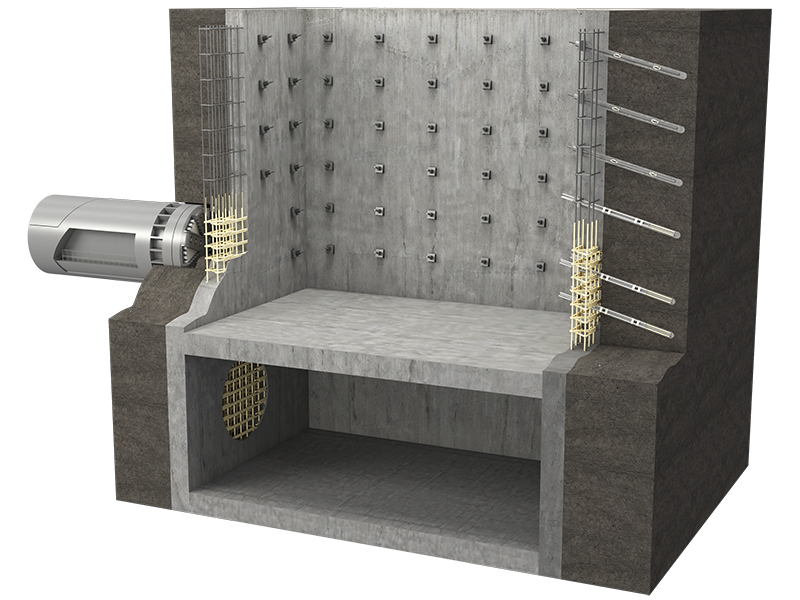

该项目于 2018 年开始施工。Dextra 参与了该项目,为车站的结构提供钢筋连接器和全自动钢筋准备设备。 钢筋/增强筋 作品。

Griptec 耦合器因其在拉伸、压缩和疲劳方面无与伦比的性能而被选中,共交付了 400,000 台。

此外,Dextra 还提供:

- 5,300 玻璃纤维增强聚合物 Astec组合螺栓 — 这些是在CBD岩洞施工现场使用的。岩洞宽度19米,可以建造两条7米长的常规隧道,这些隧道与中间段平行建造,中间段由 玻璃纤维增强聚合物 CB 螺栓,可以切割以拓宽廊道。

- 2,400 玻璃纤维增强聚合物 Geotec GR45 – 25毫米 销钉 — 每条长 11.8 米,这些 销钉 用于固定挖掘面。

- 900 玻璃纤维增强聚合物 Astec 土钉 ST50 – 41 — 这些措施用于保护几个在建车站。其中一些车站超出了项目边界,因为 玻璃纤维增强聚合物 可以留在地面上,以后可以轻松砍伐。

- 16 柔眼 — 安装在五个车站的D-Wall和钻孔桩中。

Dextra 提供支持并分享其专业知识 玻璃纤维增强聚合物 在设计阶段,生产定制形状 玻璃纤维增强聚合物 满足业主期望的解决方案。由于可切割性 玻璃纤维增强聚合物,TBM 可以在最短的时间内穿过 D-Wall 而不会造成损坏。

地铁隧道及其新车站预计将于 2025 年通车,预计将成为该市的新地标。

(照片来源:Hugh Llewelyn,网址:https://bit.ly/2S0kbAG)