阿联酋永利阿尔马里安岛

The Wynn Al Marjan Island, located in Ras Al Khaimah, United Arab Emirates, is set to be an iconic luxury destination, marking Wynn’s first foray into the Middle East. This spectacular development will feature a world-class hotel, upscale dining, entertainment venues, and extensive leisure facilities, all nestled along the pristine shores of the Arabian Gulf. With its signature blend of elegance and grandeur, the Wynn aims to offer an unparalleled experience that combines luxury, relaxation, and entertainment for visitors from around the globe.

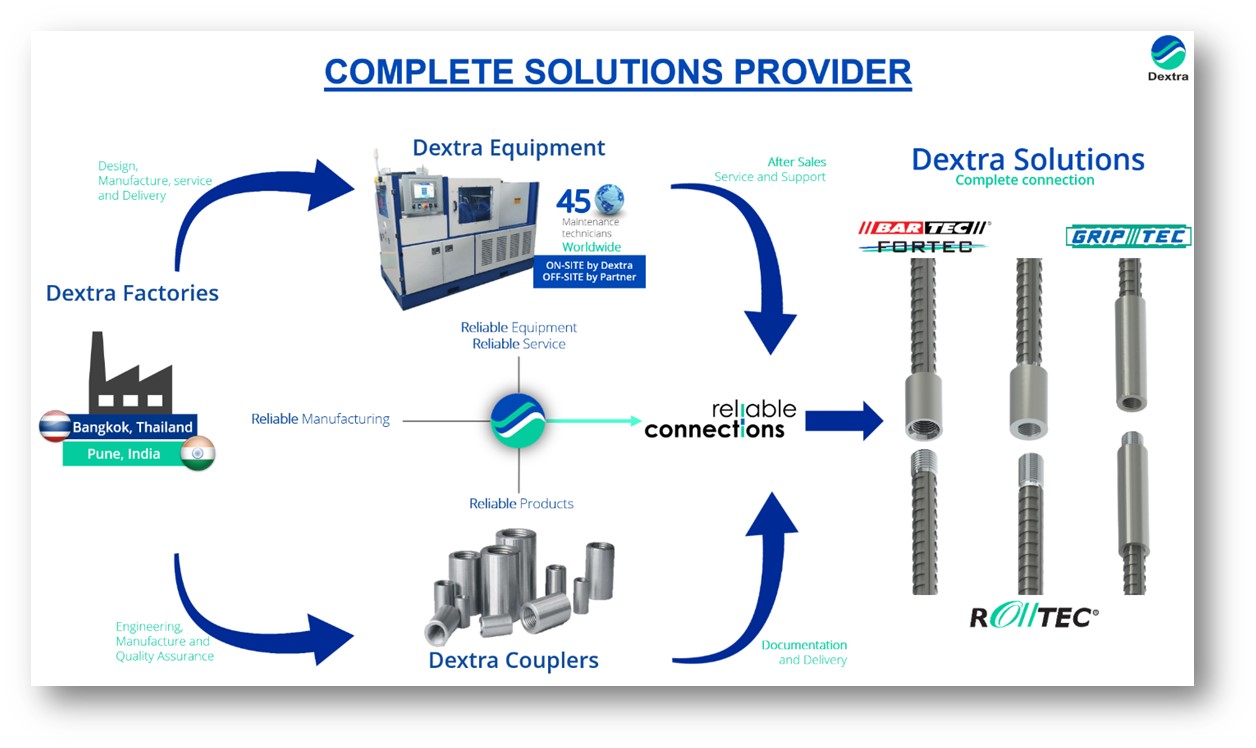

Dextra has made a substantial contribution to the construction by supplying 350,000 巴特克 couplers. These couplers are essential for the concrete slab and column connections, ensuring robust and reliable reinforcement in both vertical and horizontal applications.

Designed to meet the demanding structural requirements of large-scale developments, 巴特克 couplers are known for their superior strength and durability. Their use in the Wynn project not only supports the integrity of the structure but also accelerates construction by facilitating efficient load transfer across critical connection points.

Dextra is proud to be part of this landmark project, demonstrating their commitment to delivering high-quality solutions for premier developments worldwide.