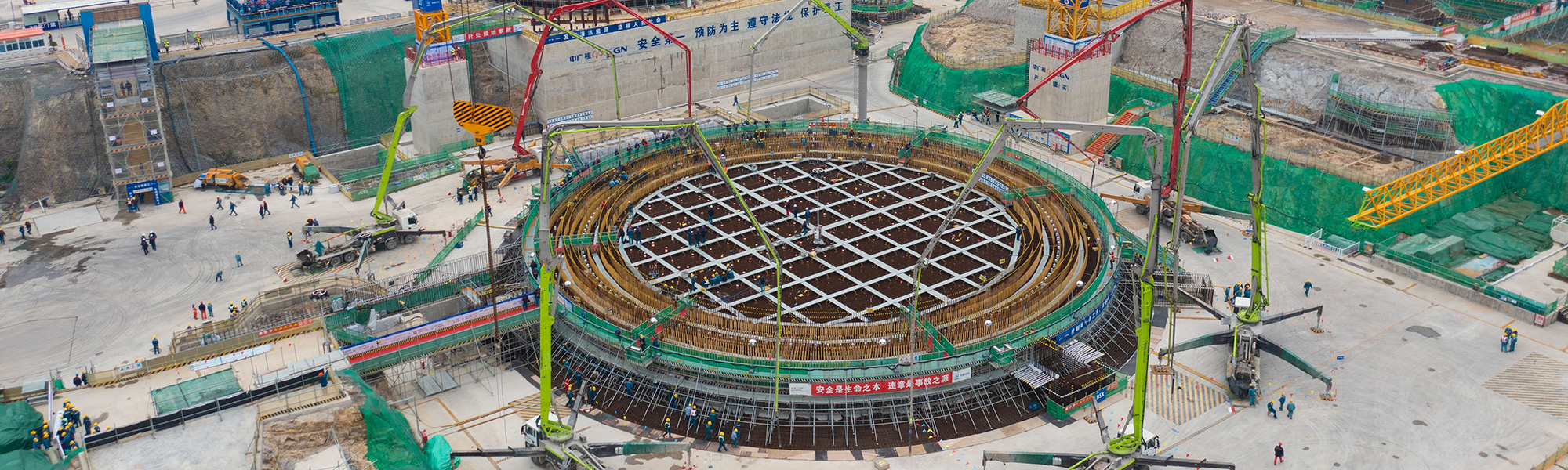

Chennai Metro Phase 2, India

The Chennai Metro Phase 2 project is set to redefine urban transportation in one of India’s largest cities, promising enhanced connectivity and efficiency. Playing a pivotal role in the success of this ambitious project, Dextra has supplied an array of cutting-edge construction solutions to meet the project’s demanding structural and safety requirements.

Ensuring Robust Connections with Bartec Rebar Couplers

Dextra supplied nearly 2 million Bartec rebar couplers, essential for creating secure connections across various structural components. These couplers have been utilized extensively in the connections for diaphragm wall (d-wall) caging and slabs, pile cages, piers, and pier caps. By ensuring high-strength rebar connections, Bartec couplers contribute to the overall durability and resilience of the metro structure, particularly important in a densely populated and busy urban environment like Chennai.

Precision Testing with Sonitec CSL Testing Tubes

To ensure the highest standards of concrete integrity, Dextra provided over 80,000 Sonitec crosshole sonic logging (CSL) testing tubes. These tubes facilitate rigorous testing of piles and d-walls, helping to identify potential flaws within the concrete structure. This meticulous testing process enables project engineers to detect and address any irregularities, safeguarding the integrity and longevity of the metro’s foundations.

Supporting Complex Structures with CR Bar 1080 Post-Tensioning Bars

For the support of double-decker piers and the pre-tensioning of U-girders, Dextra supplied 68 CR Bar 1080 post-tensioning bars. These high-strength, fully threaded bars are critical in handling the complex loads and stresses that the elevated sections of the metro will endure. The inclusion of these bars ensures that the metro can withstand heavy traffic and operational demands over time, contributing to the long-term safety and functionality of the infrastructure.

Facilitating Tunnel Boring with GFRP Soft-Eyes

In the tunneling phase, Dextra also provided 42 GFRP soft-eyes, specifically designed for tunnel boring machine (TBM) operations. These soft-eyes allow TBMs to pass through concrete walls smoothly, ensuring safe and efficient tunneling while reducing the risk of structural damage. GFRP’s non-corrosive properties make it an ideal choice for underground construction, where durability and performance are paramount.

Building a Safer, Stronger Future

Dextra’s commitment to supplying top-tier construction materials and solutions underscores its dedication to the Chennai Metro Phase 2 project. As the metro takes shape, Dextra’s innovations contribute not only to the project’s success but also to the future of Chennai’s urban infrastructure, setting new standards in construction excellence and sustainability.