卡克拉帕尔原子电站 3 号和 4 号

卡克拉帕尔原子电站是印度一座核电站,位于古吉拉特邦苏拉特河和塔皮河附近。

3 号和 4 号机组是印度第一对自行设计的 700 MW 加压重水反应堆 (PHWR),位于古吉拉特邦的卡克拉帕尔,其中两台 220 MW PHWR 机组已投入运行。

The first concrete pour for Kakrapar 3 and 4 took place in November 2010 and March 2011 respectively, after Atomic Energy Regulatory Board (AERB) approval.

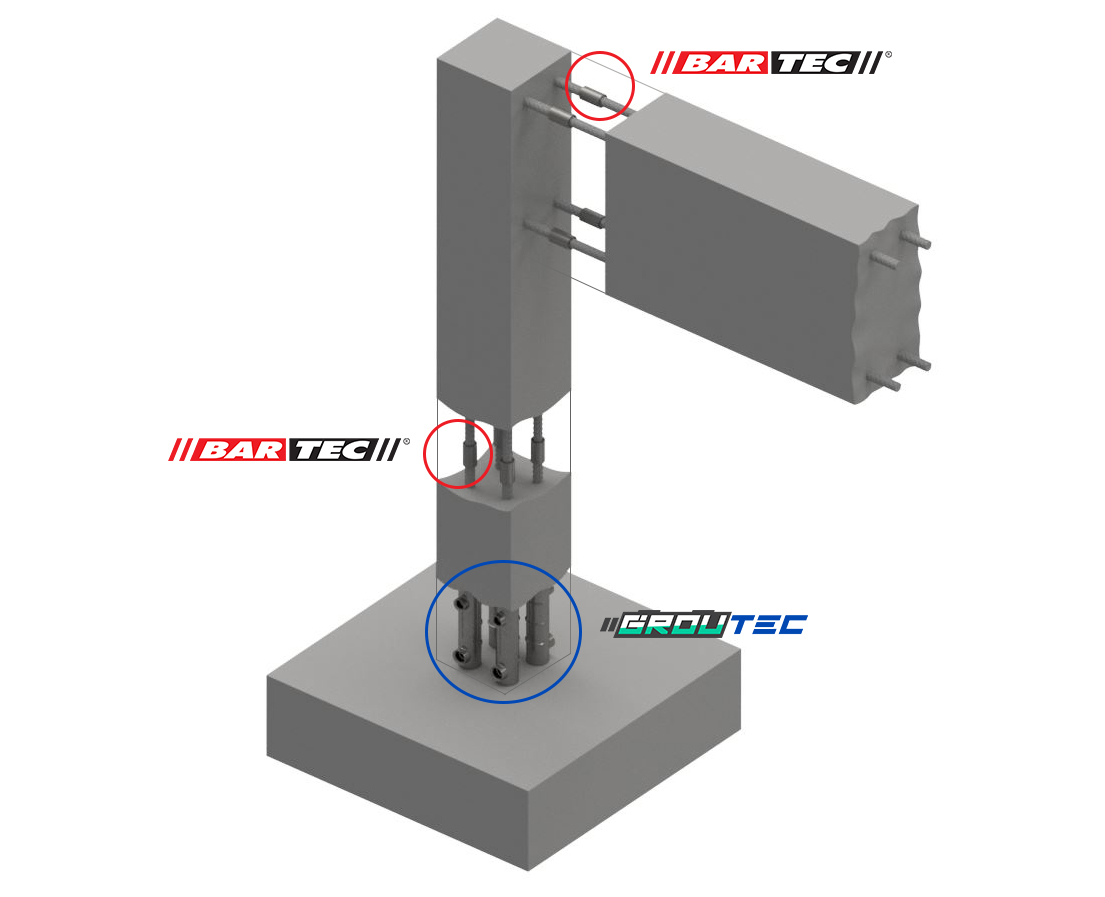

Since then, Dextra had supplied 540,000 巴特克 rebar couplers, to connect slabs and columns of reactor and control buildings.

Moreover, 联合技术公司 bolted couplers were installed to connect rebars without the need of any thread preparation.

Finally, 有头条 were mounted onto the reinforcement bar end, drastically reducing rebar congestion.

The commercial operation of Unit-3 is expected to be in March 2021 while its twin unit, Unit-4, is anticipated to start a year later.

图片来源:https://en.wikipedia.org/wiki/Kakrapar_Atomic_Power_Station,https://www.nucnet.org/news/kakrapar-3-indigenous-phwr-achieves-first-riticity-7-3-2020, https://www.asiavillenews.com/article/a-look-at-the-kakrapar-3-reactor-54367