绿金杜巴一体化太阳能联合循环电站

杜巴ISCC绿色发电厂1号是位于沙特阿拉伯西北部红海沿岸的一个大型电力基础设施项目。该项目采用ISCC(综合太阳能联合循环)技术,将50兆瓦的太阳能添加到燃气轮机和蒸汽轮机中,总发电量达500兆瓦。

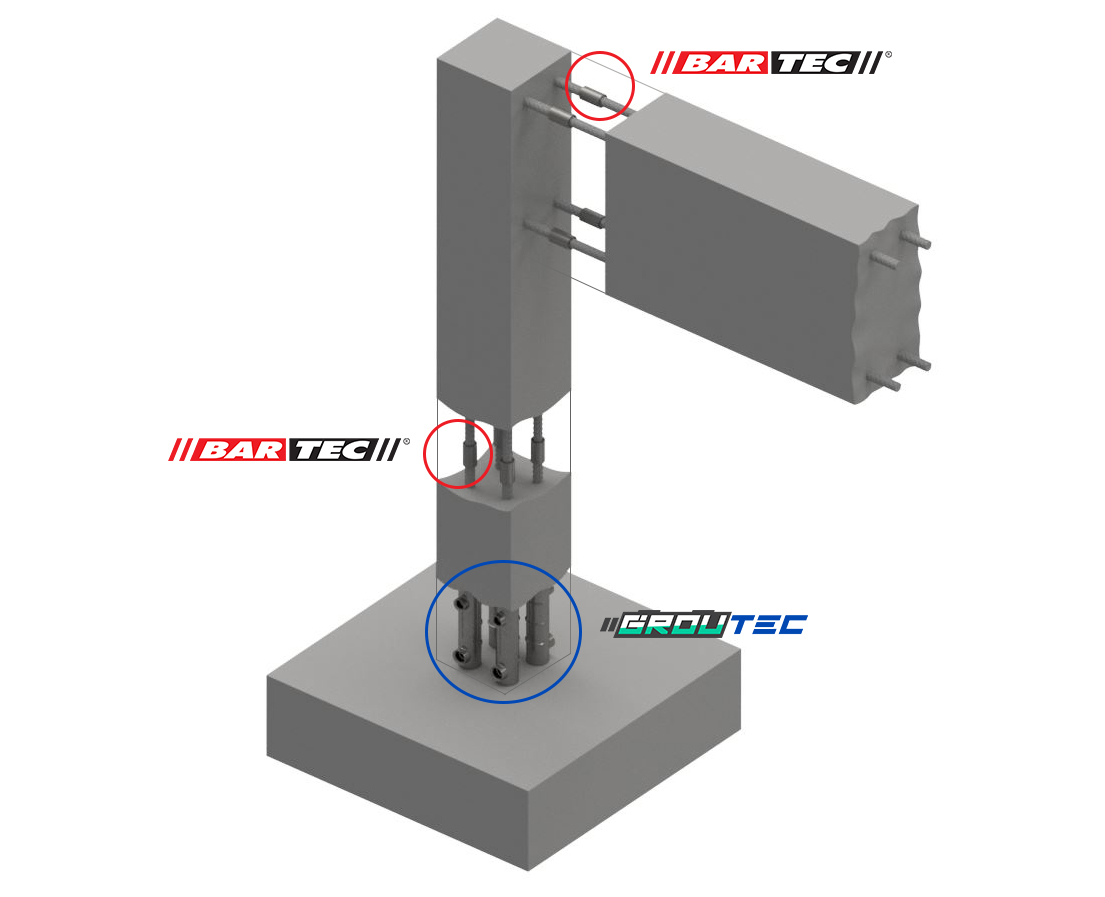

对于这个项目,Dextra 提供了 双重防腐蚀 地锚,作为泵房开挖准备工作的永久锚固解决方案。总共 264个锚点 (1080/1230 级,Ø32 和 40 毫米) 已供应并安装在 四层.

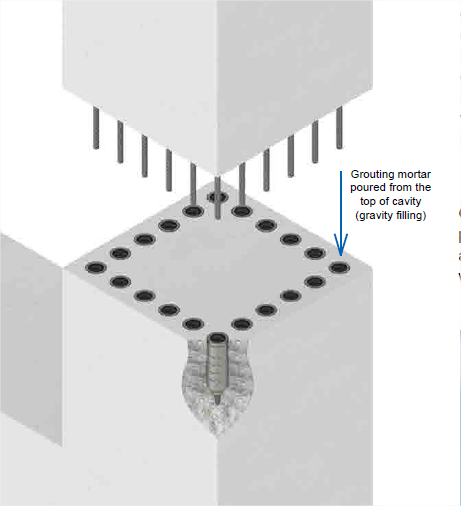

这 双重防腐蚀 锚点 为该项目提供的 在 Dextra 工厂进行预灌浆,在 钢筋和HDPE套管. 预灌浆管段在现场使用连接器重新连接。预灌浆锚不仅 节省时间并降低成本 在现场操作期间,但他们也 提升整体主播素质 确保第一层灌浆层 工厂控制环境.

现场安装由地基承包商宝华 (BAUER) 进行,该承包商执行钻孔、起重、安装、灌浆和后张拉作业。 Dextra 在安装的早期步骤中通过派遣岩土工程专家团队到现场提供指导。

一般安装顺序如下(如下图所示):

- 从运输架上拆箱后,用耦合器拼接各段,并用热缩套管覆盖。

- 将组装好的锚从组装现场运输到吊装区域(每延米 13 公斤)。

- 锚头处的布线电缆用于控制下降。注浆管也沿着锚预先安装。

- 将30米锚连同注浆管插入钻孔中。

- 灌浆、施力后,将充满油脂的头帽安装在锚头上,保持锚与外界腐蚀性环境完全隔离。

有关我们在中东的挖掘和地面解决方案的更多信息,请联系我们 迪拜办事处.