Watch an exclusive interview of Dextra team in Europe on BFM Business TV show (in French)!

Reinforcement connection solutions and their answer to challenges in construction

The construction industry is a sector that is both rich in players and in constant evolution. Rebar mechanical splices used for the connection of steel rebars in reinforced concrete constitute a niche sector, in which DEXTRA has established itself since 1983. We met Olivier Gourlet and Anton Jouravleff, respectively General Manager and Commercial Director of Dextra Europe. They explain to us the challenges of this niche market of rebar mechanical splices.

Could you please tell us about the history of the Dextra group?

The establishment of the DEXTRA group dates back to the takeover of DRAGAGES & TRAVAUX PUBLICS, a construction major in Asia, by the Bouygues group in 1986, as part of the takeover of the SCREG group. The company Dragages had a set of commercial subsidiaries intended to supply their sites in South-East Asia. Their trading activity in Hong Kong was taken over by French entrepreneurs, who are still at the head of the company today.

Simply being an importer-supplier at the start, DEXTRA quickly became a designer, manufacturer and distributor of technical solutions to meet the needs of its customers, with the spearhead of mechanical connection systems for reinforcing bars, more commonly known as couplers.

Our industrial production and technical expertise in this niche market has facilitated our global expansion. DEXTRA remains however a medium size company, owned by French shareholders, and focused on the construction sector. The Group generates US$130 million in revenues, has nearly 900 employees, and operates in more than 55 countries.

Production, historically based in Thailand, has expanded closer to its markets. Its development continues and its activity on the old continent, through its subsidiary DEXTRA Europe, now represents 25% of its turnover.

With more than 35 years of experience, DEXTRA is today the leader in this market in terms of production capacity and diversity of the countries in which it operates.

The transmission of the forces between the reinforcing bars in concrete is traditionally done by overlapping the bars between them. Raising the awareness of construction industry players to the use of couplers is therefore a major challenge?

The construction world has its tried and true habits. The mechanical connection is indeed an alternative, which aims to replace lap-splicing, either to facilitate constructability on the site, or to improve the structural performance in the event of deterioration of the concrete.

Indeed, in the case of lap-splicing, it is the integrity of the concrete which ensures the transmission of forces between the bars. If it is damaged (flaking due to corrosion of the reinforcement, explosion or earthquake), the transmission of forces is no longer ensured and the stability of the structure is thus called into question.

The awareness to be done in the field at all levels of the value chain is enormous: it must go from engineering schools to design offices to end users.

Construction needs vary depending on the type of building being constructed. How do you adapt your offer?

First of all, according to the performance required: a building will have less requirements than those of a nuclear power plant. The environment can also influence the requirements, as in the case of seismic zones. We therefore have different solutions that allow us to adapt to each of these typologies. Today, we supply couplers to a wide variety of projects: high-rise towers, metros, airports, ports, wind farms in Fécamp or nuclear power plants (such as Flamanville, Hinkley, Rosatom) where the level of requirements is at its highest.

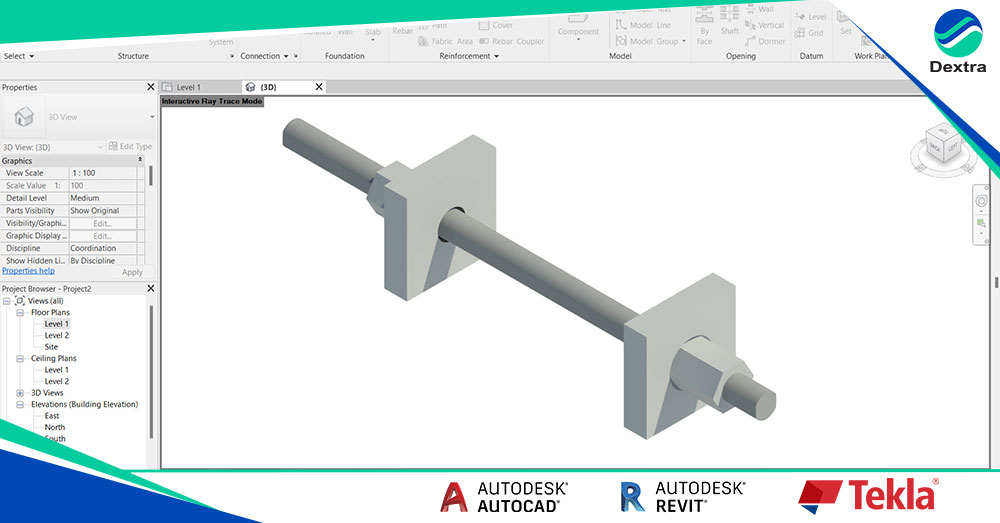

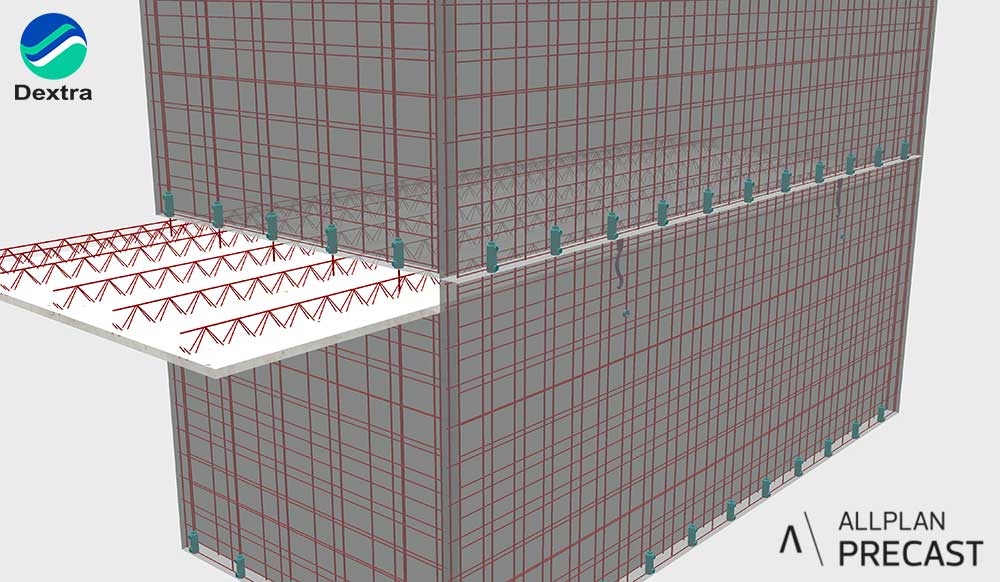

Depending on the application, the needs for in situ construction differ from the needs for repair or prefabrication. Each of its applications uses different solutions, and therefore couplers. Here again, we have developed specific solutions, which means that today we have a very diverse range to meet all these expectations.

How does DEXTRA Europe adapt to the challenge of constantly changing performance and application requirements based on new constraints?

The construction world is changing. In recent years, more stringent requirements have emerged in terms of structural fatigue and earthquake resistance. It was necessary to support these developments with additional tests on our couplers and sometimes improve our existing solutions.

In addition, in terms of applications, more and more architects and construction companies are turning to prefabrication and modularization. To meet these new needs, we have developed a system of cement grout couplers to simplify their implementation on site.

How does DEXTRA Europe approach the issue of certifications?

The construction market is very standardized while remaining very specific to each country. Although the Eurocode is a significant step forward in the process of harmonizing standards, there are still national annexes and local certification bodies that complicate the distribution of our products.

For example, in France, any splicing system must be certified by the AFCAB. The proliferation of long and costly certifications in Europe forces us to make choices even if our products meet the required requirements.

It is obviously essential to maintain technical validation of the solutions proposed, but the lack of coordination at European level ultimately represents a brake on the possible uses on each market.

How would you describe the developments in this coupler market?

It is difficult today to draw a precise picture on the growth or not of this market, because the various producers do not share figures on the evolution of their respective markets.

As far as Dextra is concerned, the sales figure has increased sharply in recent years, with more than 15 million couplers distributed worldwide in 2021. This corresponds in our opinion to an increase in market share and a general market growth.

Overall, the importance of each market remains aligned with the size of the construction market, where we find the top three in Europe: the United Kingdom, Germany and France.

What are the values advocated by the DEXTRA group?

Our values are customer satisfaction, integrity and transparency, creativity and flexibility, and accountability.

To achieve this, we are committed to maintaining control of all stages from design to use on site:

We remain in control of the quality of our products and our delivery times by producing in our own factories;

Our factories are equipped with their own test laboratory to better control our materials and manufacturing;

We design and manufacture the equipment required for the preparation of the bars ourselves;

Our engineers maintain constant support for our clients and users, first physically through our subsidiaries and our network, but also by constantly developing remote service technologies.

In this business, we are the only ones to have developed such a complete value chain.

Our R&D team constantly reflects on our solutions, to support the developments and technical constraints of our markets, as closely as possible to our customers’ expectations.

For example, we have invented a bar-end preparation equipment that incorporates an automatic performance monitoring device, which goes as far as to alert us of any slightest non-compliance, anywhere in the world.

Dextra also carries out an increasingly popular consultancy mission, thanks to the presence in the field of engineers, mostly civil engineers, able to understand drawings and technical issues, in order to provide an expert view to our partners and construction companies.

(This content was produced with SCRIBEO. The BFMBUSINESS editorial staff did not participate in the production of this content.)

Read the content in French