分类: 消息

推动可持续发展:推出适用于船用拉杆的 EPD

Dextra 集团在 2024 年泰国员工体验奖中大放异彩!

Dextra 在印度浦那的新工厂揭幕

Dextra 在香港庆祝成立 40 周年

Dextra 在印度孟买庆祝成立 40 周年

Dextra庆祝在中国成立40周年

预制高架水箱:彻底改变储水方式,确保“Har Ghar Jal”

与澳大利亚 Silva Global 建立新战略合作伙伴关系

建设更美好的未来:Dextra Group 和 Silva Global 联手推动澳大利亚基础设施和建筑行业的业务

全球工程解决方案领导者 Dextra Group 宣布与澳大利亚当地著名分销商和解决方案提供商 Silva Global 建立合作伙伴关系,这是一项旨在增强客户体验和提供独特解决方案的战略举措。此次合作对于 Dextra 集团来说是一个重要的里程碑,今年该集团将庆祝成立 40 周年。此次合作将特别关注澳大利亚的基础设施和建筑领域,将Dextra Group 的工程专业知识和Silva Global 对当地市场需求的深刻理解和反应结合起来。

本地合作伙伴优势:发挥无与伦比的专业知识

Silva Global 强大的本地影响力和对澳大利亚市场的广泛了解将在合作伙伴关系的成功中发挥关键作用。该联盟旨在利用席尔瓦快速高效反应的能力,确保及时提供服务,满足行业的苛刻要求。此外,Silva Global 全面的库存将有助于快速获取产品,最大限度地缩短交货时间并确保项目及时完成。此外,该合作伙伴关系将纳入价值工程原则,根据基础设施和建筑领域客户的具体需求提供具有成本效益的解决方案。

提高性能的尖端产品解决方案

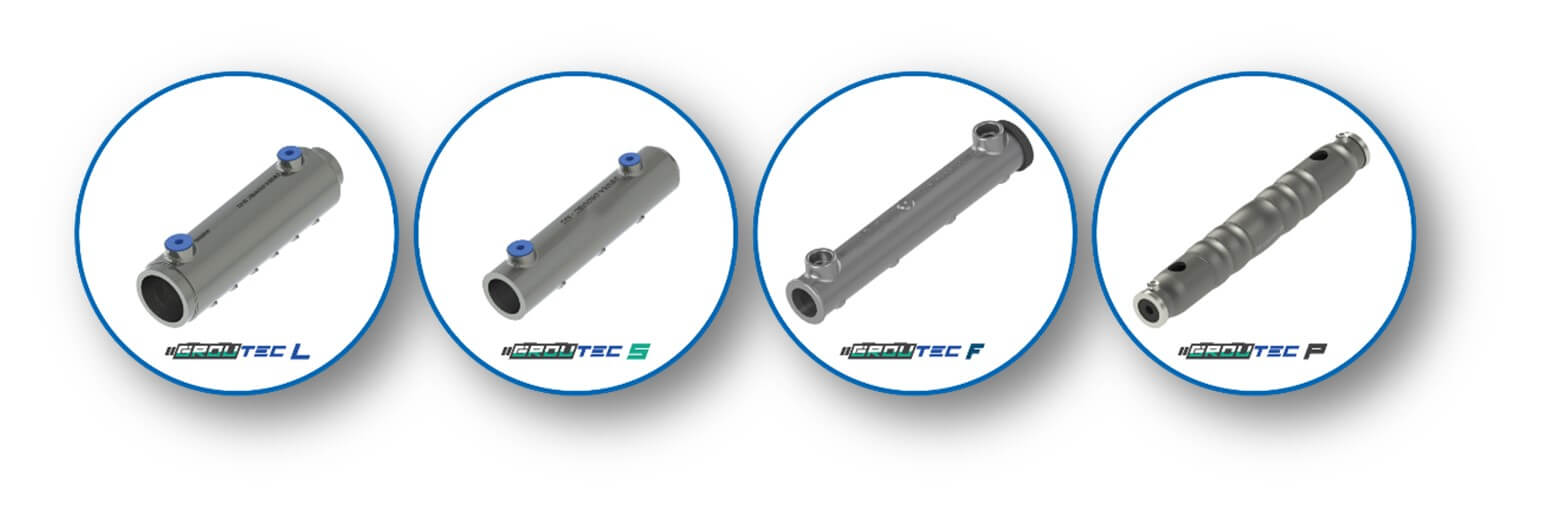

作为合作的一部分,Silva Global 将作为澳大利亚的解决方案提供商合作伙伴,向当地市场推出机械拼接系统、Griptec 和 Groutec 耦合器,以及 Dextra 的结构杆产品系列,例如后张法和建筑杆系统。 Griptec 以其核应用而闻名,可确保混凝土连接的结构完整性,而 Groutec 则为预制应用提供可靠且耐用的解决方案。这些创新产品将使澳大利亚客户能够提高其项目的质量、效率和可持续性,使他们处于行业进步的最前沿。

以客户为中心的卓越:助力成功

秉承对客户满意度的共同承诺,Dextra Group 和 Silva Global 优先考虑卓越的服务、及时的帮助和技术专业知识。通过维持高质量产品的强大库存,该合作伙伴关系将增强客户的可及性,确保他们能够快速、可靠地获得项目所需的材料。通过个性化关注和量身定制的解决方案,Dextra Group 和 Silva Global 旨在帮助客户高效、有效地实现其目标。

为客户和利益相关者带来的好处:提供卓越的结果

Dextra Group 和 Silva Global 之间的合作为客户提供了尖端技术和创新解决方案,从而改变他们的项目。通过利用 Dextra Group 的优质产品组合以及 Silva Global 的本地业务和技术能力,客户可以更快地实现其项目目标,同时最大限度地减少环境足迹。此次合作还简化了项目管理,确保顺利执行、成本控制和及时交付。客户可以期待一种全面、综合的方法,超越他们的期望并提供卓越的结果。

随着澳大利亚基础设施和建筑行业的不断发展,Dextra 集团和 Silva Global 的合作伙伴关系将在推动进步和促进可持续增长方面发挥关键作用。凭借追求卓越的共同愿景和对客户满意度的承诺,该联盟将通过提供先进的解决方案、高效的服务和突破性的产品来重塑行业。

关于德克斯达集团:

Dextra 集团是工程解决方案领域的全球知名领导者,为各行业提供尖端技术和创新产品。 Dextra 集团拥有 40 年令人自豪的传统,致力于在其所有努力中提供卓越的价值和卓越,同时将可持续发展作为我们所有活动的核心。

关于席尔瓦全球:

Silva Global 是值得信赖的本地经销商,专门为建筑行业供应材料和产品。凭借广泛的网络和对澳大利亚市场的深入了解,Silva Global 为全国各地的客户提供及时的服务和卓越的解决方案。

Dextra在广州庆祝成立40周年

非常感谢我们尊敬的合作伙伴与我们一起在中国广州庆祝我们成立 40 周年!

2023 年 6 月 15 日,我们与中国重要的合作伙伴一起庆祝了四十年的创新和成功。我们的客人享受了一场独特的庆祝活动,包括工厂参观、鸡尾酒午餐、创新更新和晚宴。这是一次难忘的聚会,充满了欢乐、友情和对我们共同成就的赞赏。

您的光临和支持使这一里程碑变得更加有意义,我们衷心感谢我们多年来共同建立的卓越合作伙伴关系。

以下是我们在广州庆祝 40 周年庆典期间分享的难忘时刻。与我们一起重温魔法并庆祝我们非凡的合作伙伴关系!