Tag: unitec

Mumbai Metro Line 2B, India

King Abdullah Financial District, Saudi Arabia

King Abdullah Financial District, Saudi Arabia

The King Abdullah Financial District (KAFD) is a multipurpose business and residential complex located in Riyadh, Saudi Arabia. The district consists of more than 50 towers and is expected to accommodate a working population of around 12,000 people.

Dextra Middle East, based in Dubai, has been involved since 2009 in supplying several building packages to Saudi Bin Ladin Group, the main contractor for the project.

Foundation Piles

To provide vertical connections in foundation piles, Dextra supplied its popular Bartec rebar coupler solution—the #1 rebar splicing solution in the Middle East—through its fabrication partners.

In addition to Bartec couplers, Dextra also supplied Unitec couplers, which were used for the continuation of bars protruding from the foundation piles. Unitec offers a flexible solution for contractors, as it does not require prior bar-end preparation. It only requires an impact wrench, making it easy to operate, especially on remote construction sites.

Raft and Columns

Bartec couplers were also used for horizontal connections in the thick foundation rafts and vertical connections in the protruding columns.

Core Wall-to-Beam Applications

In the building superstructure, Dextra Bartec couplers were used to provide horizontal connections from the core wall, enabling the insertion of second-phase starter bars needed to create the beam reinforcement.

Parque da Cidade, Brazil

Parque da Cidade, Brazil

Parque da Cidade is a multi-tower, multi-purpose green building complex located in the south of São Paulo. The project features five corporate office towers, a hotel, residential buildings, and a shopping mall.

For this project, Dextra supplied its Rolltec rebar coupler solution to contractor Odebrecht.

Rolltec is the most popular rebar splicing solution in Brazil, offering a competitive alternative to lap splices and, more importantly, enabling advanced applications that simplify project management and operations.

At Parque da Cidade, Rolltec rebar couplers were used to connect columns and beams. The solution was supported by Rolltec bar-end preparation equipment installed on-site and maintained by Dextra’s local engineers.

For this application, rebar couplers were aligned horizontally within the column reinforcement at each floor and cast into concrete. Dextra provided its couplers with thread protection caps to prevent liquid concrete from leaking into the couplers.

At a later stage of the project, continuation bars were directly connected into the couplers, providing convenient starter bars for beam or slab reinforcement.

Additionally, Dextra supplied its Unitec solution for Parque da Cidade. Unitec is a bolted coupler that does not require any rebar preparation. It was used to connect rebars protruding from two precast elements.

Jamnagar refinery expansion

Jamnagar Refinery Expansion: The World’s Largest Refinery by Production Capacity

Located in Gujarat, western India, the Jamnagar Refinery is the largest refinery in the world by production capacity. Owned by Reliance Industries, it was commissioned in 1998 and spans a vast 50 km² area.

For Phase 3 alone, more than 305,000 tons of steel reinforcement were used in a 36-month project, involving over 100,000 engineers and construction workers.

Dextra has been involved in Jamnagar since the early phases, supplying rebar splicing solutions for Phases 1, 2, and 3 of the project.

Dextra’s Rebar Splicing Solutions for Phase 3:

Three rebar coupler solutions were used in Phase 3:

- Bartec Solution

Used for cast-in-situ applications, including bar-to-bar connections in foundations, pile cages, and column cages.

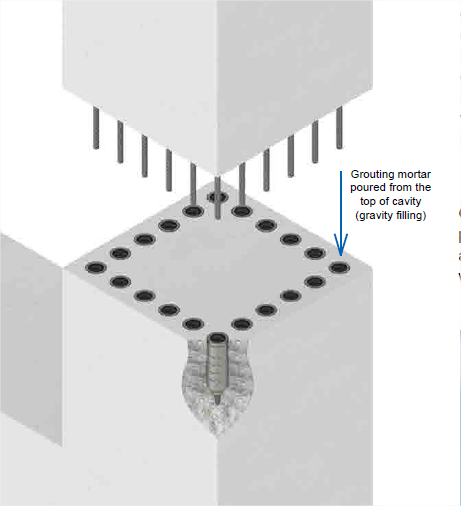

Also utilized in heavily congested rafts and pile caps to facilitate efficient rebar splicing. - Groutec Couplers

Applied to pipe racks, which were constructed from precast elements in a dedicated precast factory within the project.

Positioned in the bottom elements and filled with grout, eliminating the need for in-situ wet joints and ensuring fast, secure connections between beams and columns. - Unitec Couplers

Used in applications where rebar length was too short to allow traditional overlap connections.