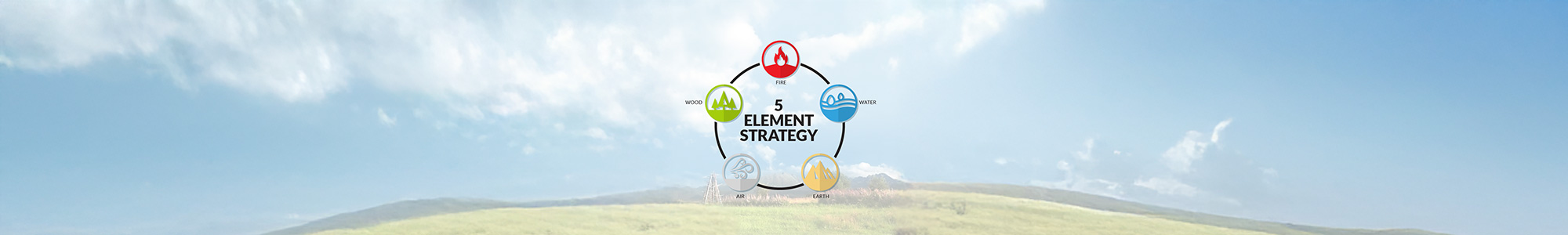

At Dextra, we take a holistic approach to environmental responsibility, drawing inspiration from the five elements—Fire, Water, Earth, Air, and Wood. This comprehensive strategy ensures that every aspect of our operations aligns with our commitment to sustainability, benefiting both our customers and the planet. Here’s how each element plays a role in our environmental initiatives and why this is important for our customers.

- Fire: Reducing Carbon Emissions through Energy Management

Our “Carbon Footprint for Organization” (CFO) program is a crucial step toward understanding and reducing our carbon emissions. By closely monitoring our electricity consumption, we aim to identify the primary contributors to our carbon footprint and focus on strategies to reduce energy use across our operations.

Customer Benefits:

- Low-Carbon Products: As we reduce our carbon footprint, customers gain access to products with lower embedded emissions, supporting their own sustainability goals.

- Cost Efficiency: Reducing energy use contributes to cost savings, which can help make our products more competitive while enhancing value for our customers.

- Water: Autonomous Water Treatment Solutions

Dextra is fully autonomous in water treatment, thanks to the advanced water treatment plants installed at our factories in Thailand and India. This ensures that all water used in our production processes is treated and reused where possible, minimizing waste and reducing our impact on local water resources.

Customer Benefits:

- Resource Responsibility: By minimizing our impact on water resources, we provide customers with products manufactured using responsible water practices, aligning with sustainable supply chain requirements.

- Environmental Assurance: Our commitment to water treatment supports environmentally sensitive projects, ensuring customers can trust our commitment to preserving natural resources.

- Earth: Integrated Waste Sorting Facilities

In Thailand, we have integrated our own waste sorting facility to manage production waste responsibly. This facility allows us to sort, recycle, and properly dispose of waste materials, minimizing landfill contributions and enhancing our waste management practices.

Customer Benefits:

- Eco-Conscious Sourcing: Dextra’s waste sorting practices mean customers are sourcing products from a company that prioritizes responsible waste management, supporting their goals of sustainable procurement.

- Reduction in Environmental Impact: Proper waste sorting reduces environmental pollution and reinforces a circular economy, adding value to customers looking to minimize their environmental footprint.

- Air: Emissions Control and Quality Standards

While not explicitly listed in the details above, “Air” is a fundamental part of Dextra’s strategy. By implementing stringent emissions control measures and adopting cleaner production processes, we ensure that our operations minimize air pollution and improve air quality around our facilities.

Customer Benefits:

- Health and Safety: Reduced emissions contribute to cleaner air quality, benefiting local communities and providing a safer environment for our workforce.

- Alignment with Green Standards: For customers aiming to meet international green building and environmental standards, our emissions control efforts ensure that Dextra products align with these rigorous requirements.

- Wood: Reforestation Efforts to Combat Deforestation

Dextra is actively involved in reforestation initiatives to combat deforestation. We regularly participate in tree-planting programs, helping restore natural habitats and reduce the carbon footprint through enhanced carbon sequestration.

Customer Benefits:

- Carbon Offset and Biodiversity: Our reforestation efforts support biodiversity and provide a natural offset for carbon emissions, helping customers align with biodiversity goals and nature-based solutions.

- Commitment to Sustainability: Customers benefit from partnering with a company that supports global efforts to fight deforestation, adding social and environmental value to their own sustainability programs.

Why Dextra’s Holistic Approach Matters for Our Customers

Our five-element environmental strategy goes beyond individual initiatives to create a comprehensive, responsible approach that meets today’s high sustainability standards. For our customers, this approach provides a range of valuable benefits:

- Enhanced Brand Value: Partnering with Dextra means choosing a supplier with a firm commitment to environmental responsibility, which can enhance the sustainability credentials of our customers.

- Alignment with Global Standards: Our holistic environmental strategy aligns with key global sustainability standards, providing customers with products that meet increasingly rigorous environmental and social expectations.

- Trusted, Sustainable Products: By integrating these five elements into our operations, we ensure that our products are made responsibly and transparently, giving our customers confidence in the quality and sustainability of the solutions we offer.

We believe that our holistic environmental strategy benefits not only our company but also our customers and the planet. By aligning our operations with the elements of Fire, Water, Earth, Air, and Wood, we are committed to building a sustainable future together.