Dextra is proud to announce its newest partnership with NCS Steel, a dynamic new player in the Portuguese construction industry. As the latest addition to Dextra’s growing network of cut & bend fabricators in Europe, this collaboration reinforces our commitment to delivering high-quality reinforcement solutions for major infrastructure projects across the continent.

A Powerhouse Backed by Industry Leaders

Though newly established, NCS Steel brings a wealth of expertise to the market. It is a joint venture between three of Portugal’s most prominent steel suppliers:

- Nordesfer – Armazéns de Ferro S.A.

- J. Justino das Neves S. A.

- Metalofarense

By combining their extensive industry experience and resources, NCS Steel is poised to elevate reinforcement solutions in Portugal’s growing construction sector.

State-of-the-Art Facility in São Lourenço

Strategically located in São Lourenço, near Lisbon, NCS Steel’s brand-new facility is designed to set new benchmarks in precision, efficiency, and product quality. The plant is equipped with advanced machinery and cutting-edge technology to meet the rising demand for reinforcement-related products and services.

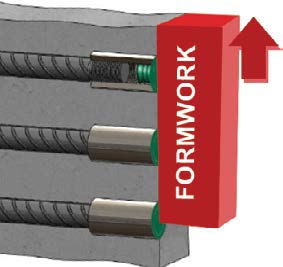

Expanding Access to Dextra’s Rolltec Coupler System

A key aspect of this partnership is the integration of Dextra’s Rolltec coupler system into NCS Steel’s portfolio. Rolltec, known for its superior strength, reliability, and ease of installation, has been a preferred reinforcement solution in major European projects, including:

- Storstrøm Bridge (Denmark): A critical infrastructure project enhancing connectivity between Zealand and Falster.

- Oosterweel Ring Road (Antwerp, Belgium): One of Europe’s largest urban mobility projects aimed at transforming the city’s transport network.

By bringing Rolltec to the Portuguese market, NCS Steel will enable local contractors and engineers to benefit from high-performance reinforcement technology, ensuring faster, safer, and more efficient construction.

A Shared Vision for the Future

This partnership represents more than just a business collaboration, it is a shared commitment to innovation,

For more information about our reinforcement solutions, feel free to browse our website or visit the Rolltec page or NCS Steel website for further information.