Tag: #Construction

Chennai Metro Phase 2, India

Posted on by Kansuda Visesthanakorn

Chennai Metro Phase 2, India

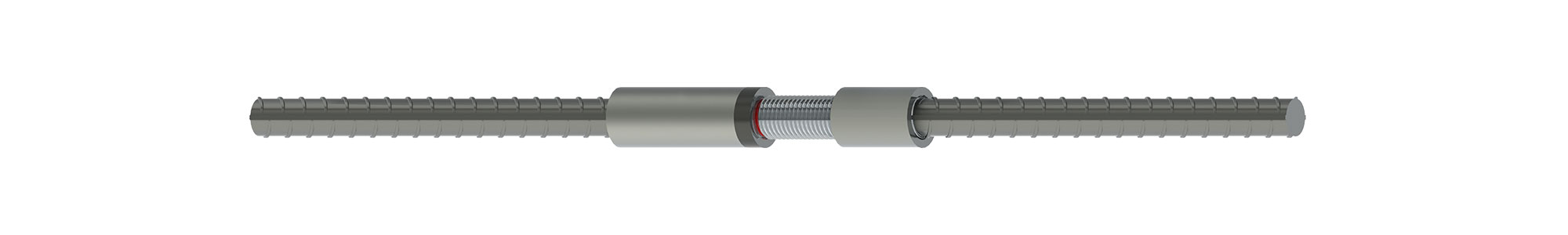

The Chennai Metro Phase 2 project is set to redefine urban transportation in one of India’s largest cities, promising enhanced connectivity and efficiency. Playing a pivotal role in the success of this ambitious project, Dextra has supplied an array of cutting-edge construction solutions to meet the project’s demanding structural and safety requirements. Ensuring Robust Connections with Bartec Rebar Couplers Dextra supplied nearly 2 million Bartec rebar couplers, essential for creating secure connections across various structural components. These couplers have been utilized extensively in the connections for diaphragm wall (d-wall) caging and slabs, pile cages, piers, and pier caps. By ensuring high-strength rebar connections, Bartec couplers contribute to the overall durability and resilience of the metro structure, particularly important in a densely populated and busy urban environment like Chennai. Precision Testing with Sonitec CSL Testing Tubes To ensure the highest standards of concrete integrity, Dextra provided over 80,000 Sonitec crosshole sonic logging (CSL) testing tubes. These tubes facilitate rigorous testing of piles and d-walls, helping to identify potential flaws within the concrete structure. This meticulous testing process enables project engineers to detect and address any irregularities, safeguarding the integrity and longevity of the metro’s foundations. Supporting Complex Structures with CR Bar 1080 Post-Tensioning Bars For the support of double-decker piers and the pre-tensioning of U-girders, Dextra supplied 68 CR Bar 1080 post-tensioning bars. These high-strength, fully threaded bars are critical in handling the complex loads and stresses that the elevated sections of the metro will endure. The inclusion of these bars ensures that the metro can withstand heavy traffic and operational demands over time, contributing to the long-term safety and functionality of the infrastructure.Sharing Some Mumbai Office Inauguration Glimpses!

Posted on by Kansuda Visesthanakorn

We’re thrilled to announce the relocation of our Mumbai office to a new space at:

Our team is excited to keep delivering exceptional service and driving innovation from this new hub. We are deeply grateful for the opportunities and support that have brought us to this milestone.

Our commitment to excellence remains unwavering, and we look forward to serving you better from our new address!

Dextra’s Quarterly Newsletter: Connection #38

Posted on by Kansuda Visesthanakorn

The Mumbai Metro Line 2B is a vital infrastructure project designed to enhance public transport in Mumbai. Dextra has contributed to the project by supplying advanced construction solutions to ensure the structure’s durability and strength.

For the elevated section’s U-girders, Dextra provided CR Bar 1080 for both stressing and pre-tensioning. Additionally, fully threaded bars were supplied for temporary stressing, offering flexible and secure connections between precast segments.

For the elevated section’s U-girders, Dextra provided CR Bar 1080 for both stressing and pre-tensioning. Additionally, fully threaded bars were supplied for temporary stressing, offering flexible and secure connections between precast segments.

Dextra also delivered Unitec couplers, enabling efficient rebar connections without pre-threading, ensuring strong, seamless structural continuity on-site. Moreover, Sonitec CSL testing tubes were provided for concrete pile integrity testing.

By contributing these advanced materials and solutions, Dextra is supporting the development of a reliable metro system that will meet Mumbai’s growing transportation needs for years to come.

Dextra also delivered Unitec couplers, enabling efficient rebar connections without pre-threading, ensuring strong, seamless structural continuity on-site. Moreover, Sonitec CSL testing tubes were provided for concrete pile integrity testing.

By contributing these advanced materials and solutions, Dextra is supporting the development of a reliable metro system that will meet Mumbai’s growing transportation needs for years to come.

For the elevated section’s U-girders, Dextra provided CR Bar 1080 for both stressing and pre-tensioning. Additionally, fully threaded bars were supplied for temporary stressing, offering flexible and secure connections between precast segments.

For the elevated section’s U-girders, Dextra provided CR Bar 1080 for both stressing and pre-tensioning. Additionally, fully threaded bars were supplied for temporary stressing, offering flexible and secure connections between precast segments.

Dextra also delivered Unitec couplers, enabling efficient rebar connections without pre-threading, ensuring strong, seamless structural continuity on-site. Moreover, Sonitec CSL testing tubes were provided for concrete pile integrity testing.

By contributing these advanced materials and solutions, Dextra is supporting the development of a reliable metro system that will meet Mumbai’s growing transportation needs for years to come.

Dextra also delivered Unitec couplers, enabling efficient rebar connections without pre-threading, ensuring strong, seamless structural continuity on-site. Moreover, Sonitec CSL testing tubes were provided for concrete pile integrity testing.

By contributing these advanced materials and solutions, Dextra is supporting the development of a reliable metro system that will meet Mumbai’s growing transportation needs for years to come. More about our latest projects

Cairo Monorail Bridge, Egypt

High-strength tension rods were used as hangers for the bowstring monorail bridge to maintain its structural integrity and durability.

Introducing Durabar Carpet: the latest breakthrough from Dextra!

Made from Durabar GFRP rebar, this latest patented Durabar Carpet offers unparalleled versatility for construction projects. Designed for efficiency, its ability to be cut effortlessly in any direction ensures maximum material savings.

Key Features:

• Bar from Ø 6mm to Ø 16mm

• Standard length: 5.8m

• Customizable lengths: 2m to 5.8m

• Flexible spacing: 100mm to 600mm

Watch Now: FibreCraft Insights – Exploring GFRP in Construction

Dextra is excited to present FibreCraft Insights, our brand-new video series dedicated to Glass Fibre Reinforced Polymer (GFRP) rebar in the infrastructure construction industry.

Hosted by our experts in composite solutions, this series offers valuable insights into the growing role of GFRP in modern construction.

The first three episodes are available now, where we delve into an introduction to the material and its advantages, the unique technical features of GFRP, and real-world applications.

Follow our LinkedIn to stay tuned for more episodes!

Dextra is excited to present FibreCraft Insights, our brand-new video series dedicated to Glass Fibre Reinforced Polymer (GFRP) rebar in the infrastructure construction industry.

Hosted by our experts in composite solutions, this series offers valuable insights into the growing role of GFRP in modern construction.

The first three episodes are available now, where we delve into an introduction to the material and its advantages, the unique technical features of GFRP, and real-world applications.

Follow our LinkedIn to stay tuned for more episodes! Recent activities

Our Collaboration with Makin Juta

Watch our latest interview with Makin Juta, one of our esteemed distributors and partners in Malaysia, and discover our collaboration on the iconic KLCC Lot L and M Podium project, where Bartec was selected as the trusted solution. Watch the interview

Tension Rods & PT Bars EPD Verified

Dextra’s tension rods and post-tensioning bars are Environmental Product Declaration (EPD) verified and listed on the EPD Hub, joining our previously verified couplers, GFRP rebars, marine tie bars, ground anchors, rock bolts, and Sonitec. Read more

Headed Bars Now CE Marked with ETA

Bartec, Fortec, and Rolltec headed bars are now CE marked with European Technical Assessments (ETA). Tested by Concrefy and certified by Kiwa, these are our first CE-marked products, meeting the essential requirements. Read more

Upcoming events

World of Concrete India

16-18 Oct 2024

Port Dev. MEA Forum, United Arab Emirates

21-22 Oct 2024

ASEAN Ports & Logistics, Malaysia

10-11 Sep 2024

Bauma

China

26-29 Nov 2024

CTBUH Asia Conference, Thailand

3-4 Dec 2024

Dextra Celebrates Paralympic Success with Thai Boccia Athletes

Posted on by Kansuda Visesthanakorn

Dextra had the pleasure of visiting the Cerebral Palsy Sports Association of Thailand (CPSAT) once again, following our initial visit in June. During that visit, we donated funds to support these dedicated athletes in their training and competitions, and we even had the opportunity to play a friendly boccia match together. Since then, these remarkable athletes have achieved outstanding success at the recent Paralympic Games in France, winning a gold medal and two bronze medals in Individual Boccia.

This return visit allowed us to personally congratulate the athletes on their incredible accomplishments. Their perseverance and commitment have not only brought pride to Thailand but also inspired us all at Dextra. We are honored to have supported them on their journey and are excited to continue backing their future endeavors.

Through these ongoing efforts, Dextra reaffirms our dedication to giving back to the community and celebrating the triumphs of individuals who embody the spirit of resilience and determination.

Bartec, Fortec, Rolltec Headed Bars Achieve CE Marking

Posted on by Kansuda Visesthanakorn

Dextra’s Bartec, Fortec, and Rolltec Headed Bars Achieve CE Marking—A Milestone in Engineering Excellence

Dextra is proud to announce a significant milestone in our journey of delivering high-quality construction solutions: our Bartec, Fortec, and Rolltec large headed bars, ranging from 16 to 40mm in diameter, have been assessed and granted European Technical Assessments (ETA) and are now officially CE marked. This achievement is based on the stringent regulations under EAD 160012-01-0301, edition April 2021, certified by Kiwa, one of the largest certification bodies in the world.

CE marking signifies our products meet the essential requirements for headed reinforcing steel bar within the European Economic Area. It also reinforces our commitment to providing safe, reliable, and high-performance solutions in the construction industry.

To ensure that our products meet the highest standards, rigorous testing was conducted by Concrefy; the most recognized and experienced laboratory in the Netherlands, in accordance with ISO 15698. These tests verified the mechanical properties, durability, and overall performance of our headed bars, ensuring they comply with stringent European standards.

A First Step Toward a Larger Vision

This achievement marks the beginning of an exciting new chapter for Dextra. These are our first products to receive CE marking, and we are already working on expanding this certification to more of our product range. Our goal is to continue delivering innovative solutions that meet and exceed industry standards globally.

CE marking is not just a badge of compliance; it is a testament to our unwavering dedication to engineering excellence, quality, and customer satisfaction. As we continue to push the boundaries of what is possible in the construction sector, we are committed to setting new benchmarks in product performance and safety.

Stay tuned as we bring more CE-marked innovations to the market, driving the construction industry forward with cutting-edge solutions designed to last.

About Dextra

Dextra is a leading provider of engineered construction products and solutions, specializing in high-performance rebar coupler systems and other advanced engineered construction technologies. With a global presence and a reputation for quality, Dextra continues to lead the industry in innovation and customer satisfaction.

Bartec-Fortec Headed bars - ETA-24-0219

Rolltec Headed bars - ETA-24-0268

Mumbai Metro Line 2B, India

Posted on by Kansuda Visesthanakorn

Mumbai Metro Line 2B, India

The Mumbai Metro Line 2B, an essential link connecting several key areas of the city, is a significant infrastructure project aimed at alleviating Mumbai’s traffic congestion and providing efficient public transport. As part of this ambitious project, Dextra has made a valuable contribution, supplying engineered construction materials to ensure the durability and reliability of the structure.

CR Bar 1080 for U-Girder Stressing and Pre-Tensioning

One of the critical components of the project is the elevated section of the metro, which relies on U-girders for support. To enhance the strength and resilience of these U-girders, Dextra supplied its innovative CR Bar 1080 cold-rolled fully threaded post-tensioning bars. These bars, with a diameter of 75mm, are specifically designed to withstand high stress during both U-girder stressing and pre-tensioning operations. The hexagonal nuts provided as part of the system allow for secure fastening and easy adjustment, ensuring precise tensioning to meet the structural demands.

Fully Threaded (FT) Bar for Segment Stitching and Temporary Stressing

For segment stitching and temporary stressing operations during the construction of the metro viaduct, Dextra supplied its fully threaded (FT) bars. These bars provide secure connections between precast segments and offer flexibility for adjustments during the stitching process, ensuring that the structural alignment is perfect before the segments are permanently joined.

Unitec Couplers for Rebar Connections

In addition, Dextra supplied Unitec couplers, designed for connecting rebars at construction sites without the need for pre-threading. These couplers offer a convenient and robust solution, allowing for seamless connection of two rebars, ensuring structural continuity and strength without delays in the construction process.

Sonitec CSL Testing Tubes for Concrete Pile Integrity

In addition to supplying post-tensioning bars, Dextra also provided Sonitec Crosshole Sonic Logging (CSL) testing tubes for the integrity testing of the concrete piles supporting the metro structures. These tubes enable highly accurate non-destructive testing of the concrete, allowing engineers to detect any potential flaws or weaknesses in the piles. This testing is vital for ensuring the piles meet the necessary strength and quality standards, thereby supporting the entire metro system safely and effectively.

Enhancing Metro Connectivity with Quality Solutions

As the Mumbai Metro Line 2B progresses towards completion, Dextra’s contributions to the project highlight its role in providing advanced engineering solutions for infrastructure development. The combination of CR Bar 1080 for post-tensioning, fully threaded bars for segment stitching, Unitec couplers for rebar connection, and Sonitec CSL testing tubes for pile integrity showcases Dextra’s commitment to quality, innovation, and safety in major construction projects.

By contributing to this key metro line, Dextra is playing a part in shaping the future of urban mobility in Mumbai, ensuring that the metro system will be reliable and capable of supporting the city’s growing transportation needs for years to come.

Bartec/Fortec Bridging CAD/BIM Tools Available

Posted on by Kansuda Visesthanakorn

Bartec/Fortec Bridging Coupler is now available on AutoCAD, Revit, and Tekla for all your construction design and detailing needs!

Ideal for connecting bars that can’t be brought butt-to-butt—perfect for complex prefabricated cages—our Bridging Coupler simplifies rebar connections, helping you streamline your projects.

Start integrating it into your designs today!

Central Kowloon Route (CKR) – Central Tunnel, Hong Kong

Posted on by Kansuda Visesthanakorn

Central Kowloon Route (CKR) – Central Tunnel, Hong Kong

Dextra played a pivotal role in the construction of the Central Kowloon Route (CKR) – Central Tunnel project in Hong Kong by supplying Fortec+ couplers, along with steel rock bolts, expandable friction bolts, umbrella pipes, and post-tensioning bars for tunneling works. These mechanical rebar couplers were integral in ensuring strong and reliable connections within the road tunnel structure, meeting the stringent requirements for safety and durability.

The CKR, a major infrastructure project aimed at improving traffic flow across Kowloon, required advanced construction techniques. Dextra’s Fortec+ couplers, used in locations such as precast panels, tunnel access points, and driveways, contributed significantly to the project’s structural integrity and long-term performance. The Fortec+ system includes a rebar preparation process in which the threaded bar end is proof tested with a tensile load, ensuring non-destructive testing within the elastic zone of the reinforcing bar.

Image credit: Central Kowloon Route – Highways Department

Neo Factory Phase 1, Thailand

Posted on by Kansuda Visesthanakorn

Neo Factory Phase 1, Thailand

Dextra has played a key role in the construction of the Neo Factory Phase 1 in Pathum Thani, Thailand, one of the country’s leading consumer product manufacturers. By supplying essential Bartec and Groutec S systems for precast column connections, Dextra ensured the structural integrity of this significant industrial facility.

Bartec, renowned for its mechanical splicing capabilities, and Groutec S, designed for secure and easy installation of precast elements, were crucial in making the construction process efficient and reliable. Dextra’s involvement in the Neo Factory project underscores its commitment to providing high-quality, innovative products that support the demands of modern construction, contributing to the continued growth of Thailand’s industrial sector.