Triumph Motorcycles Office and Factory, Thailand

Dextra is proud to have played a key role in the construction of the Triumph Motorcycles Office & Factory in Chonburi, Thailand, by supplying high-performance rebar connection solutions for the precast structure.

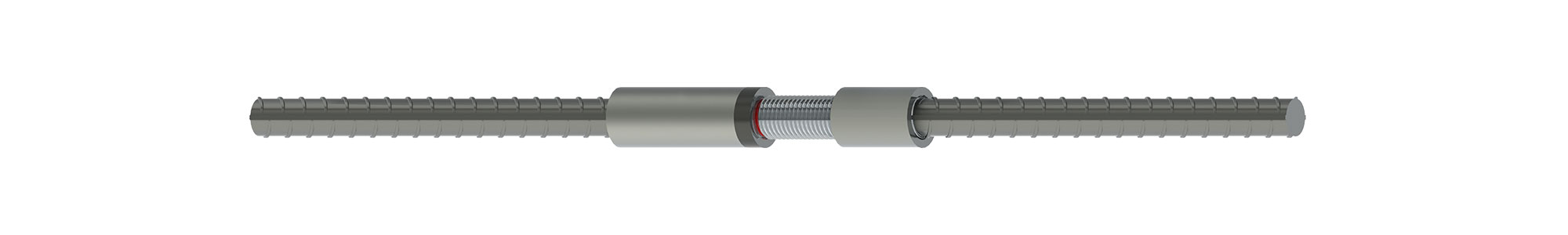

For this project, Dextra provided Groutec S 32mm couplers and Bartec standard and weldable couplers (diameter 16-32mm), supporting the reinforcement of precast columns. The structural system combined Groutec and Peikko’s Column Shoe, a hybrid approach that enhances construction efficiency, structural integrity, and installation speed.

By integrating Dextra’s advanced rebar splicing solutions, the project benefited from high-strength, reliable connections, reducing on-site labor and ensuring seamless assembly of the precast components. This contribution aligns with Dextra’s commitment to innovative, high-quality construction solutions that meet the demands of modern infrastructure.

Download now:

Download now: