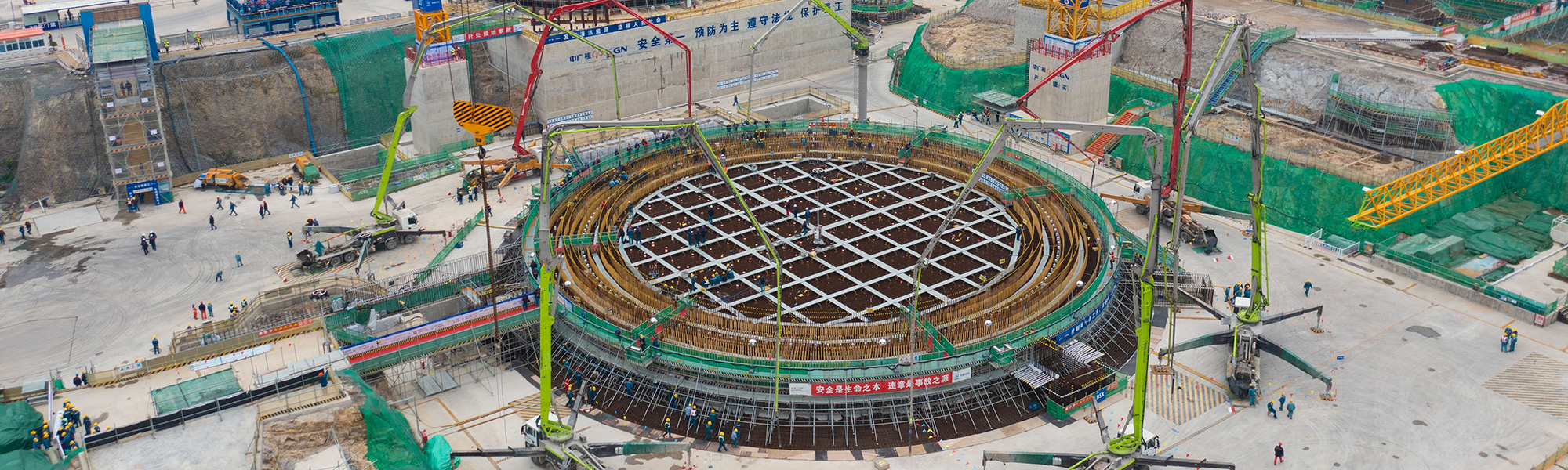

АЭС Саньяо 1 и 2, Китай

Декстра успешно поставил 340 000 Гриптек Соединительные муфты для ударопрочной конструкции корпуса АЭС № 1 и № 2, оснащенной усовершенствованными реакторами HPR1000 Hualong.

Гриптек, признанная единственной проверенной системой сращивания 100%, завоевала доверие более десяти ядерных реакторов по всему миру, укрепив свою репутацию надежности и безопасности в условиях высоких рисков. Строгие процессы обеспечения качества системы гарантируют, что каждая муфта соответствует строгим стандартам, требуемым для ядерных применений, обеспечивая непревзойденную производительность и долговечность.

Одна из выдающихся особенностей Гриптек является его высокопроизводительное оборудование для подготовки конца прутка. Это современное оборудование может похвастаться впечатляющей скоростью обработки от 30 до 45 секунд на конец прутка, что значительно повышает эффективность строительства. Кроме того, оборудование рассчитано на эксплуатацию одним оператором, что оптимизирует использование рабочей силы.

Более того, Декстра является первым производителем продукции гражданского строительства с сертифицированной системой управления качеством ISO19443 для ядерной безопасности. Эта сертификация подчеркивает Декстраприверженность компании высочайшим стандартам безопасности и качества в ядерной отрасли, демонстрирующая стремление компании к совершенству и надежности.

Проект атомной электростанции Саньяо является ключевым компонентом стратегической инициативы Китая по расширению мощностей атомной энергетики, что имеет жизненно важное значение для удовлетворения растущих потребностей страны в энергии при одновременном сокращении выбросов углерода. Поставляя Гриптек муфты, Декстра играет решающую роль в обеспечении безопасности и эффективности этого проекта.