В строительной отрасли устойчивость становится все более важным фактором. Одной из областей, где можно достичь значительных экологических преимуществ, является использование арматурных муфт вместо традиционных методов перекрытия. В этой статье рассматривается устойчивость арматурных муфт, подчеркивая их влияние на выбросы CO2, экономию затрат, сокращение отходов и эффективность транспортировки.

Сокращение выбросов CO2

Традиционные методы нахлеста требуют дополнительных отрезков арматуры для создания необходимого нахлеста, что приводит к увеличению расхода материала и более высоким выбросам CO2. Напротив, арматурные муфты устраняют необходимость в нахлесте, напрямую сокращая количество требуемой арматуры. Исследования показали, что использование арматурных муфт может сократить выбросы CO2 примерно на 90% на соединение по сравнению с традиционными методами нахлеста. Это сокращение достигается за счет снижения производства материалов и менее энергоемких производственных процессов.

Экономия затрат на сырье

Использование арматурных муфт приводит к значительной экономии затрат на сырье. Устраняя перекрытия, подрядчики могут закупать меньше арматуры, что не только снижает затраты, но и минимизирует воздействие на окружающую среду, связанное с производством стали. Исследования показывают, что внедрение арматурных муфт может привести к сокращению использования закупленной арматуры до 17,95% (Оптимизация использования арматуры и обеспечение устойчивости на основе приоритета специальной длины: пример использования механических муфт в стенах в грунте (mdpi.com). Такое снижение потребности в материалах способствует снижению общей стоимости проекта и поддерживает более устойчивые методы строительства.

Сокращение отходов

Одним из ключевых преимуществ арматурных муфт является их способность сокращать отходы. Традиционные методы наложения часто приводят к излишкам арматуры, которые необходимо обрезать и выбрасывать, что способствует образованию строительных отходов. С другой стороны, арматурные муфты позволяют создавать точные соединения без необходимости резки, тем самым минимизируя отходы. Такой подход не только экономит ресурсы, но и снижает воздействие строительных проектов на окружающую среду.

Эффективный транспорт

Транспортировка арматуры — еще одна область, где арматурные муфты предлагают преимущества устойчивости. При традиционных методах перекрытия увеличенный объем требуемой арматуры приводит к более частым и крупным поставкам, что увеличивает расход топлива и выбросы CO2. Арматурные муфты уменьшают общий объем требуемой арматуры, что приводит к меньшему количеству поставок и снижению выбросов, связанных с транспортировкой. Такая эффективность в логистике еще больше повышает устойчивость строительных проектов.

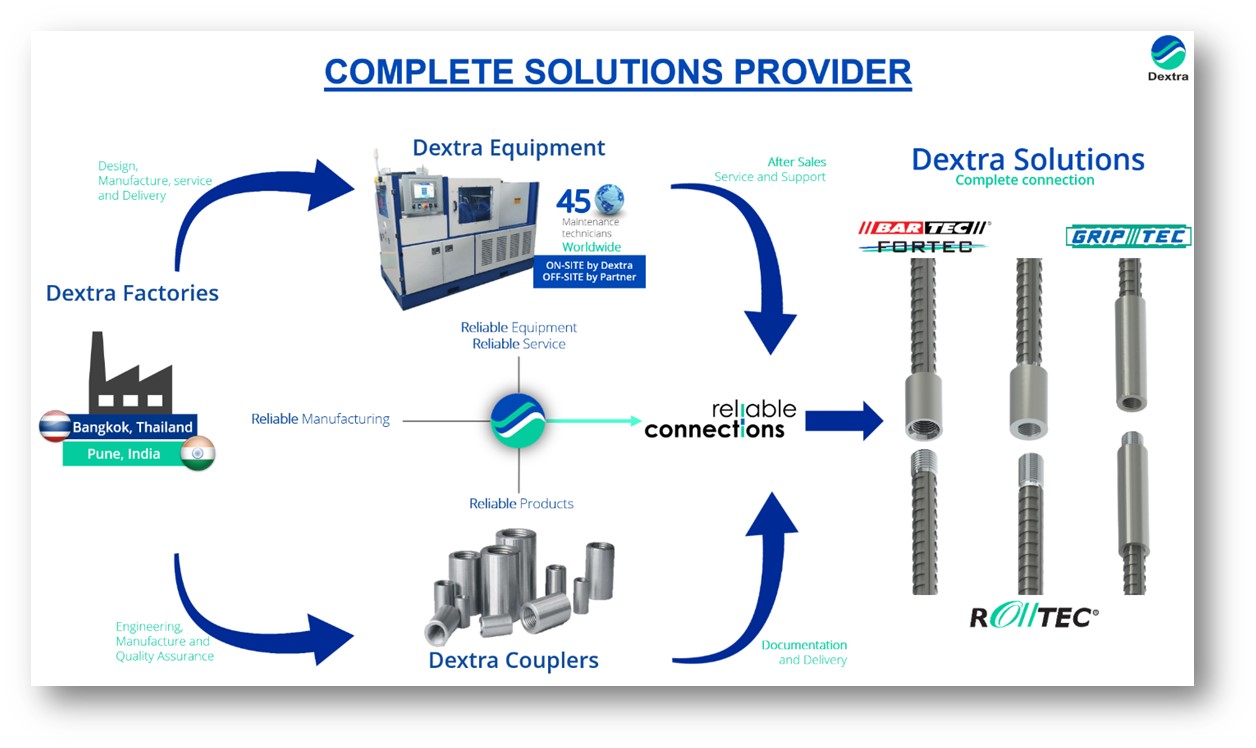

Прозрачность и подотчетность с EPD Dextra

Dextra предприняла значительные шаги в направлении устойчивого развития, внедрив Экологические декларации продукции (EPD) для наших арматурных муфт. EPD предоставляют прозрачную и проверенную информацию о воздействии продукции на окружающую среду на протяжении всего ее жизненного цикла. Предлагая EPD для наших арматурных муфт, Dextra демонстрирует приверженность прозрачности и ответственности в построении более устойчивого будущего.

Эти EPD охватывают весь спектр арматурных муфт Dextra, включая Bartec®, Griptec® и Rolltec®, и подробно описывают экологические характеристики этих продуктов от добычи сырья до утилизации по окончании срока службы. Такой уровень прозрачности позволяет подрядчикам принимать обоснованные решения на основе надежных данных, гарантируя, что их выбор арматурных муфт соответствует их целям устойчивого развития.

Почему подрядчикам следует сделать этот переход

Для подрядчиков решение перейти от традиционных методов перекрытия к арматурным муфтам должно быть обусловлено как структурными, так и экологическими соображениями. Арматурные муфты не только обеспечивают надежное и прочное соединение, но и предлагают значительные преимущества в плане устойчивости.

В заключение, использование арматурных муфт представляет собой убедительный аргумент для подрядчиков, стремящихся повысить устойчивость своих строительных проектов. За счет снижения выбросов CO2, сокращения расходов, минимизации отходов и повышения эффективности транспортировки арматурные муфты предлагают более экологичную и экономичную альтернативу традиционным методам перекрытия. Переход не только поддерживает экологические цели, но и способствует долгосрочной жизнеспособности и успеху строительных проектов.