India’s maritime sector is advancing with the New Dry Dock Project at Cochin Shipyard, a state-of-the-art facility designed to support larger vessel construction and ship repairs.

Led by L&T Construction, the 310-meter-long dry dock features a 600-ton gantry crane and a high-load-bearing dock floor, making it one of the region’s most advanced marine infrastructures. This expansion will strengthen India’s shipbuilding capabilities, enabling the construction of aircraft carriers and other large vessels.

Dextra played a key role in this landmark project by supplying 550 tons of Grade 500 Marine Tie Bars, ensuring the dock’s structural integrity. Chosen for its expertise in marine reinforcement, Dextra delivered high-strength, precision-engineered tie bars designed to withstand extreme marine conditions.

Dextra is excited to participate in bauma, the world’s leading trade fair for the construction industry, held in Munich, Germany, on April 7-13, 2025. Our team of professionals from around the world is delighted to welcome you at Stand No. 506, Hall C3.

Discover our latest innovations designed to elevate construction efficiency and performance:

Решения для армирования бетона: Offering a complete range of rebar couplers for cast-in-situ, precast, and repair applications, along with high-strength GFRP rebars for corrosion-resistant reinforcement. Читать далее

Инженерные барные системы: High-performance bar systems specifically designed for applications such as roof and façade support, bridge tensioning, and marine structure anchoring. Читать далее

Geotechnical Engineering Solutions: Steel and composite (FRP) anchoring systems tailored for soil stabilization, tunneling, mining, and deep foundation applications. Читать далее

Our latest projects

Wynn Al Marjan Island, UAE

Dextra supports this project in Ras Al Khaimah by supplying 350,000 Bartec couplers, ensuring robust slab and column connections.

New Pamban Bridge, India

India’s first vertical lift railway sea bridge uses FT bars and tension rods to ensure the stability of its steel tower and lifting mechanism.

Grand Paris Line 16-18, France

Fortec couplers and Sonitec CSL tubes were supplied, ensuring durable connections and reliable foundation testing.

Triumph Factory, Thailand

Dextra played a key role, supplying Groutec S and Bartec couplers to provide efficient connections for the precast column structure.

Recent activities

Dextra India Certified Great Place To Work®

We are proud to be certified by Great Place To Work® India, a recognition based on our employees’ feedback, reflecting our commitment to creating a supportive and inspiring work culture. Читать далее

Dextra-Normet Sign MoU for Sustainable FRP

Dextra has signed a MOU with Normet to collaborate on developing and supplying advanced FRP solutions for underground mining and tunneling, to promote innovation in the industry. Читать далее

Dextra Reaches 30K Followers on LinkedIn

A heartfelt thank you to our 30,000 followers for being part of our journey—if you haven’t joined us yet, follow Dextra on LinkedIn to stay connected with the latest innovations and insights! Follow us

ISO 19443 Achieved in India and Thailand

Our manufacturing plants in India have successfully obtained the ISO 19443 Nuclear Certification for the first time, while our Thailand plants have achieved a successful renewal. Читать далее

Tension Rod Earns ETA Under EOTA

Dextra Tension Rod System has achieved the European Technical Assessment (ETA-24/1184), validating its exceptional reliability, performance, and compliance with European standards. Читать далее

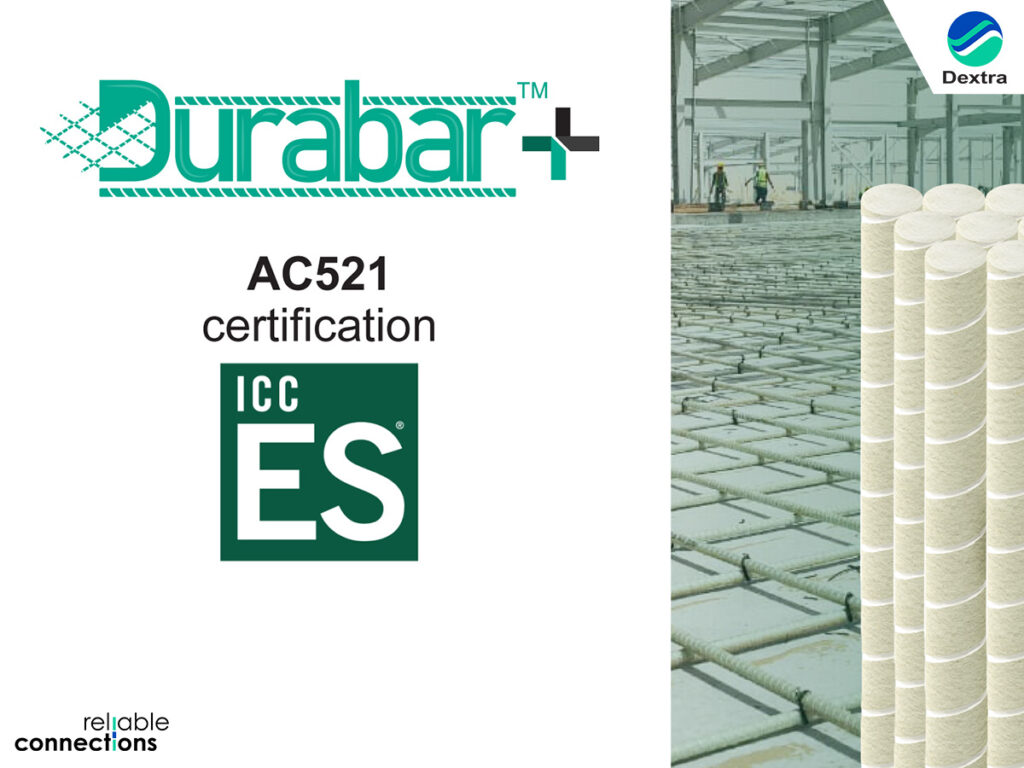

Durabar+ GFRP Rebar Achieves ICC-ES AC521

Upcoming events

Construction and Infrastructure Professionals – Ensuring project compliance with certified, high-performance reinforcement.

Construction and Infrastructure Professionals – Ensuring project compliance with certified, high-performance reinforcement. Structural Engineers & Designers – Using Durabar+ confidently in calculations and structural designs.

Structural Engineers & Designers – Using Durabar+ confidently in calculations and structural designs. Regulatory Authorities & Code Enforcers – Supporting the industry’s shift towards standardization and advanced materials.

Regulatory Authorities & Code Enforcers – Supporting the industry’s shift towards standardization and advanced materials.

Merry Christmas & Happy New Year!

Merry Christmas & Happy New Year!

The highly anticipated One Bangkok has officially opened on October 25, 2024, redefining Bangkok’s skyline as the city’s largest integrated mixed-use district. Spanning 1.83 million sq. m., it features premium offices, luxury hotels, residences, retail spaces, and cultural hubs

The highly anticipated One Bangkok has officially opened on October 25, 2024, redefining Bangkok’s skyline as the city’s largest integrated mixed-use district. Spanning 1.83 million sq. m., it features premium offices, luxury hotels, residences, retail spaces, and cultural hubs