In today’s rapidly evolving construction industry, collaboration is key to delivering cutting-edge solutions that address the growing demands for efficiency, safety, and sustainability. This philosophy is at the heart of the collaboration between Dextra and Peikko, two global leaders who have come together to create a hybrid precast connection system that combines the best of both worlds: Dextra’s Groutec Couplers e Peikko’s Column Shoes.

This innovative system was successfully implemented in the Triumph Motorcycle Office and Factory project in Thailand, showcasing how collaboration can drive excellence.

The Hybrid Advantage

The hybrid precast system merges the strengths of column shoes and grouted sleeves to maintain the continuity of reinforcement in precast structures. This system has proven especially valuable in seismic zones and heavily reinforced elements.

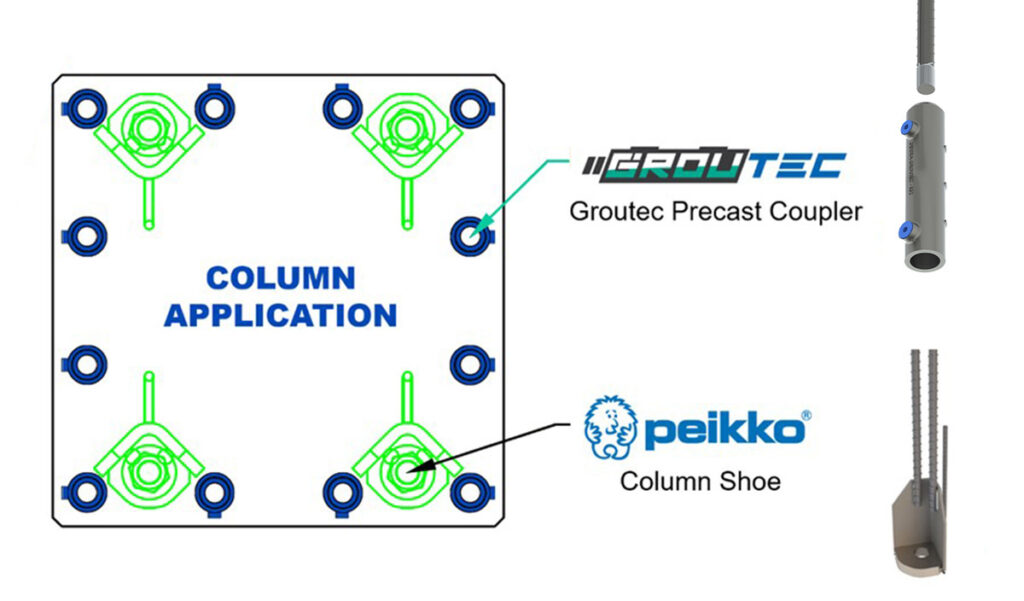

Column shoes e Acopladores Groutec are well-known products used to create connections between precast columns. A combination of the two – referred to as ‘hybrid precast connection’ has been utilized in several markets, particularly those with seismic requirements.

From a structural viewpoint, column shoes e Acopladores Groutec are both designed to maintain the continuity of reinforcement through the joints of precast elements. In the case of heavily reinforced elements, it might be challenging to accommodate all necessary column shoes within the column cross-section. In such cases, combining column shoes with Acopladores Groutec may prove to be a cost-effective alternative.

With this solution, column shoes are intended to secure the stability of the column during the erection stage, while Acopladores Groutec complement the column shoes by transferring loads applied to the structure in the final stage. The term ‘erection stage’ refers to the stage when the joint has not been grouted, and ‘final stage’ refers to when the joint is fully grouted and hardened.

Column shoes enable precast columns to be erected without props or braces, which improves the speed of erection and allows for other construction activities to proceed unimpeded, as braces and props do not obstruct corridors, thus ensuring the continuity of the construction process without distraction. Groutec ensures rebar continuity at the “final stage” of erection.

Key Benefits of the System:

- Faster Installation: Columns were installed without props or braces, reducing the installation time significantly.

- Enhanced Safety: Eliminating bracing minimized site hazards.

- Neat Finish: The method ensured a clean, professional result with no need for additional tidying.

- Cost-Effective: Fewer materials and faster processes saved time and money. Groutec contributes reliable connections while saving costs on material and labor.

Triumph Motorcycles Office and Factory: A Case Study in Success

Completed in December 2024, the Triumph Motorcycle Office and Factory spans an impressive 89,077 sq.m and features 128 precast columns installed in a record-breaking time. Dextra and Peikko’s hybrid solution played a critical role in achieving these results.

This collaboration enabled Thai Obayashi, the project’s contractor, to achieve exceptional speed, safety, and quality.

A Future Built on Collaboration

O Triumph Motorcycles Office and Factory project exemplifies what can be achieved when industry leaders combine their strengths. As Dextra and Peikko, we believe that partnerships like ours are the future of construction innovation. Together, we can deliver solutions that exceed expectations and set new standards for the industry.

Let’s continue to lead through collaboration, making the construction industry stronger, safer, and more efficient for all.