Porto Tanger Med 2

Tanger Med 2 is the expansion of Tanger Med, a multipurpose deep-water seaport located a few kilometers east of Tangier, Morocco, facing Gibraltar.

The port expansion aims to increase the yearly capacity of the largest port in Africa by 5.2 million containers.

For this large infrastructure project, Dextra supported contractor Bouygues with a rebar splicing solution for the reinforcement of the caissons.

A Dextra forneceu seu Rolltec solution, which is AFCAB-certified, a requirement for this project. Two Rolltec machines were installed to support the threading activities, completing 360,000 threads in total (180,000 Rolltec couplers).

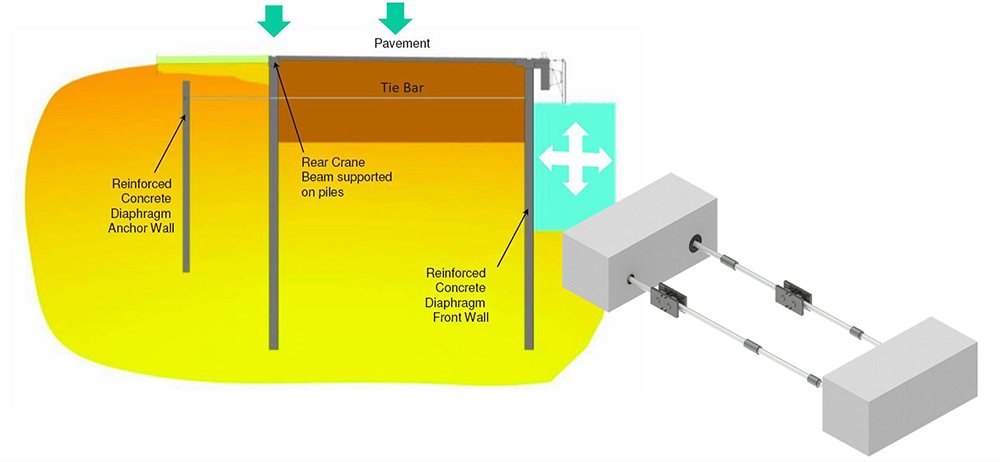

The couplers were used in the reinforcement of the caissons, which were as tall as 20 to 24 meters. The couplers provided:

- Temporary openings to solve congestion issues in the reinforcement within the caisson, creating safe passages for men and equipment during the installation phase.

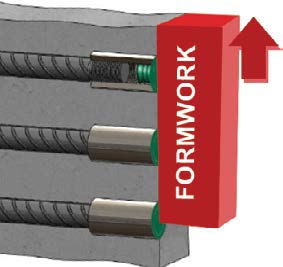

- Horizontal wall-to-slab connections (from the inside of the caisson perimeter to the slab). For this application, couplers were left pending, allowing the slip form to go up.