SeaWorld Abu Dhabi, Emirados Árabes Unidos

O SeaWorld Abu Dhabi é um parque temático de vida marinha e um centro de pesquisa, resgate e reabilitação de animais em construção. A inauguração está prevista para 2023 na Ilha Yas, em Abu Dhabi, Emirados Árabes Unidos.

Será o primeiro parque do SeaWorld fora dos EUA, operando sob licença da SeaWorld Parks & Entertainment. A empresa Miral, sediada em Abu Dhabi, é a proprietária e operadora do projeto.

A Dextra forneceu 400.000 Bartec acopladores para conexão e reforço de colunas, vigas e lajes.

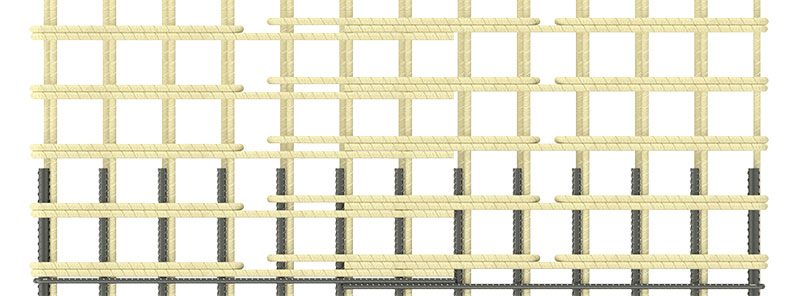

Além disso, 20.000 metros lineares de corte Vergalhões de GFRP (polímero reforçado com fibra de vidro) foram instaladas nas lajes de revestimento das piscinas, substituindo as barras de aço como a escolha preferencial.

Graças à sua durabilidade e natureza livre de corrosão, o GFRP é um material ideal para estruturas de concreto expostas à água.

Fonte das imagens: https://www.constructionweekonline.com/projects-and-tenders/267779-construction-of-mirals-seaworld-abu-dhabi-hits-40-milestone, https://www.thenationalnews.com/lifestyle/things-to-do/2023/05/22/seaworld-abu-dhabi-opens-with-star-studded-event/