Construindo um Futuro Mais Forte: Dextra Group e Silva Global unem forças para impulsionar negócios nos setores de infraestrutura e construção da Austrália

Num movimento estratégico que visa melhorar a experiência do cliente e fornecer soluções únicas, o Grupo Dextra, líder global em soluções de engenharia, anunciou a sua parceria com a Silva Global, um importante distribuidor local e fornecedor de soluções na Austrália. Esta colaboração representa um marco significativo para o Grupo Dextra, que celebra o seu 40º aniversário este ano. A parceria se concentrará especificamente nos setores de infraestrutura e construção na Austrália, reunindo a experiência em engenharia do Grupo Dextra e o profundo conhecimento e reatividade da Silva Global às exigências do mercado local.

Vantagem de parceiro local: trazendo conhecimento incomparável para o primeiro plano

A forte presença local da Silva Global e o amplo conhecimento do mercado australiano desempenharão um papel fundamental no sucesso da parceria. A aliança visa alavancar a capacidade da Silva de reagir com rapidez e eficiência, garantindo a pronta entrega de serviços que atendam aos exigentes requisitos do setor. Além disso, o estoque abrangente da Silva Global permitirá acesso rápido aos produtos, minimizando prazos de entrega e garantindo a conclusão oportuna dos projetos. Além disso, a parceria incorporará princípios de engenharia de valor, oferecendo soluções económicas adaptadas às necessidades específicas dos clientes nos sectores das infra-estruturas e da construção.

Soluções de produtos de ponta para desempenho aprimorado

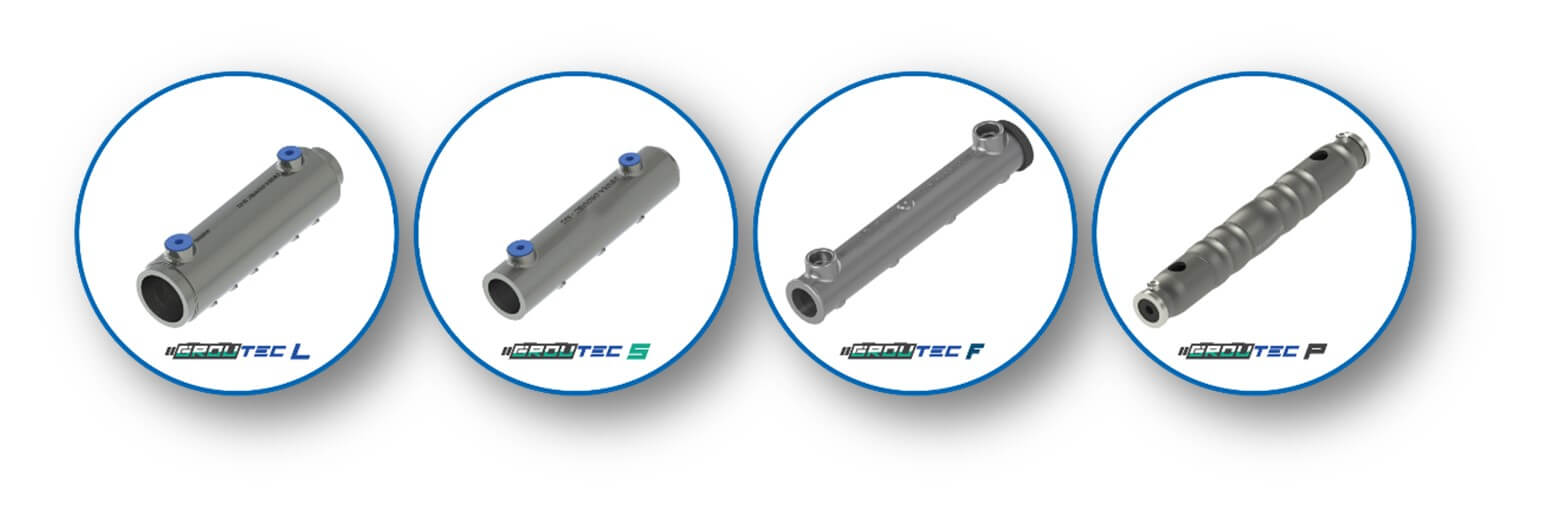

Como parte da colaboração, a Silva Global atuará como parceira fornecedora de soluções para a Austrália, introduzindo sistemas de emenda mecânica, acopladores Griptec e Groutec, bem como a linha de produtos de barras estruturais da Dextra, como sistemas de pós-tensionamento e barras arquitetônicas, para o mercado local. . A Griptec, conhecida por suas aplicações nucleares, garante a integridade estrutural das ligações de concreto, enquanto a Groutec fornece soluções confiáveis e duráveis para aplicações pré-moldadas. Esses produtos inovadores capacitarão os clientes australianos a melhorar a qualidade, a eficiência e a sustentabilidade de seus projetos, posicionando-os na vanguarda dos avanços da indústria.

Excelência Focada no Cliente: Capacitando o Sucesso

Com um compromisso comum com a satisfação do cliente, o Grupo Dextra e a Silva Global priorizam um serviço excepcional, assistência imediata e conhecimento técnico. Ao manter um estoque robusto de produtos de alta qualidade, a parceria aumentará a acessibilidade dos clientes, garantindo que tenham acesso rápido e confiável aos materiais necessários para seus projetos. Através de atendimento personalizado e soluções sob medida, o Grupo Dextra e a Silva Global visam capacitar os clientes para atingirem seus objetivos de forma eficiente e eficaz.

Os benefícios para clientes e partes interessadas: entrega de resultados excepcionais

A colaboração entre o Grupo Dextra e a Silva Global oferece aos clientes acesso a tecnologias de ponta e soluções inovadoras que irão transformar os seus projetos. Ao aproveitar o portfólio de produtos de qualidade do Grupo Dextra e a presença local e as capacidades técnicas da Silva Global, os clientes podem atingir os objetivos dos seus projetos mais rapidamente, ao mesmo tempo que minimizam a sua pegada ambiental. A parceria também agiliza o gerenciamento de projetos, garantindo boa execução, controle de custos e entrega pontual. Os clientes podem esperar uma abordagem abrangente e integrada que supere as suas expectativas e proporcione resultados excepcionais.

À medida que os setores de infraestrutura e construção na Austrália continuam a evoluir, a parceria do Grupo Dextra e da Silva Global está preparada para desempenhar um papel crucial na condução do progresso e na promoção do crescimento sustentável. Com uma visão partilhada de excelência e um compromisso com a satisfação do cliente, esta aliança irá remodelar a indústria, fornecendo soluções avançadas, serviços eficientes e produtos inovadores.

Sobre o Grupo Dextra:

O Grupo Dextra é um renomado líder global em soluções de engenharia, oferecendo tecnologias de ponta e produtos inovadores para diversos setores. Com um legado orgulhoso que abrange 40 anos, o Grupo Dextra está empenhado em fornecer valor e excelência excepcionais em todos os seus empreendimentos, mantendo a sustentabilidade no centro de todas as nossas atividades.

https://www.dextragroup.com/

Sobre Silva Global:

A Silva Global é um distribuidor local de confiança especializado no fornecimento de materiais e produtos para a indústria da construção. Com uma extensa rede e profundo conhecimento do mercado australiano, a Silva Global oferece atendimento rápido e soluções excepcionais para clientes em todo o país.

https://silva-global.com/