Doha Metro, Gold Line – Al Sadd C-Ring Station

The Doha Metro is a rapid transportation system, designed as an integral component to the larger Qatar rail network. This country wide mega-scale infrastructural project consists of 300km of rail and 100 stations. The rail network to reduce traffic congestion, and to connect the people of Qatar with the rest of the GCC region. At the city scale, currently under construction, the metro is projected to be operational by the end of 2019. It will serve Doha and its surrounding suburbs with stations located in all major nodes of the metropolis. Doha Metro will be operating both at grade and below grade, with the majority of the metro project being underground. Complex tunneling and soil retaining solutions by Dextra were utilized in the construction of this project.

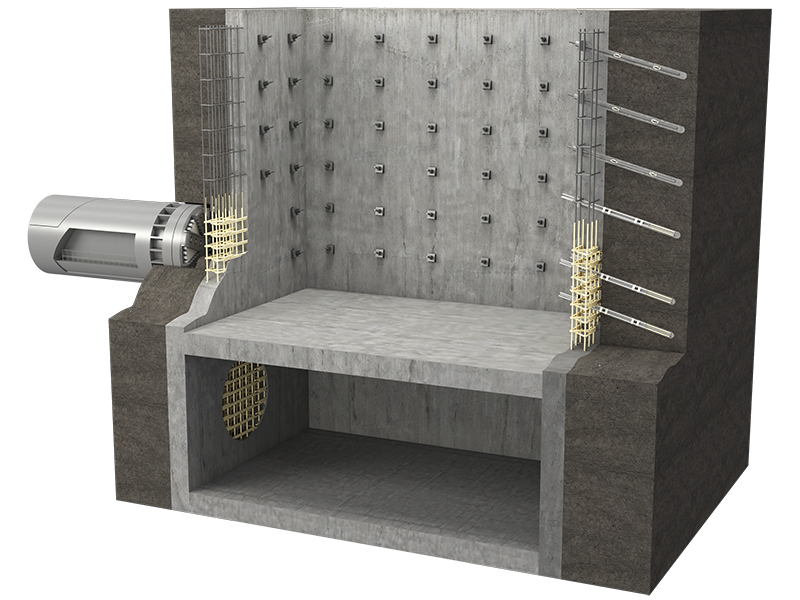

Glass Fiber Reinforced Polymers (GFRP) as Tie-back anchors to retain soil

To eliminate concerns of encroachment, and obstacle for future construction projects, the Diaphragm Wall (D-Wall) at Al Sadd C-Ring Station were post-tensioned anchored with ASTEC Active Active Anchor. These high performance, fully cut-able GFRP anchors were chosen by ALSYJ JV contractors and the D-Wall anchors of choice. This innovative solution was chosen because it can be cut by Tunnel Boring Machines (TBM) or standard excavation equipment, it also doesn’t need to be removed from the ground even in temporary applications. For Al Sadd C-Ring Station 7,113 strands for GFRP rebars were used to make approximately 700 ground retaining anchors used in the D-WALL around that station.