MultiRio Container Terminal

The MultiRio Container Terminal, located in the Rio de Janeiro Port, specializes in the import/export of finished goods. To increase its shipping capacity by at least 50%, MultiRio launched an expansion project in 2012 to add extra quay length and accommodate more containers.

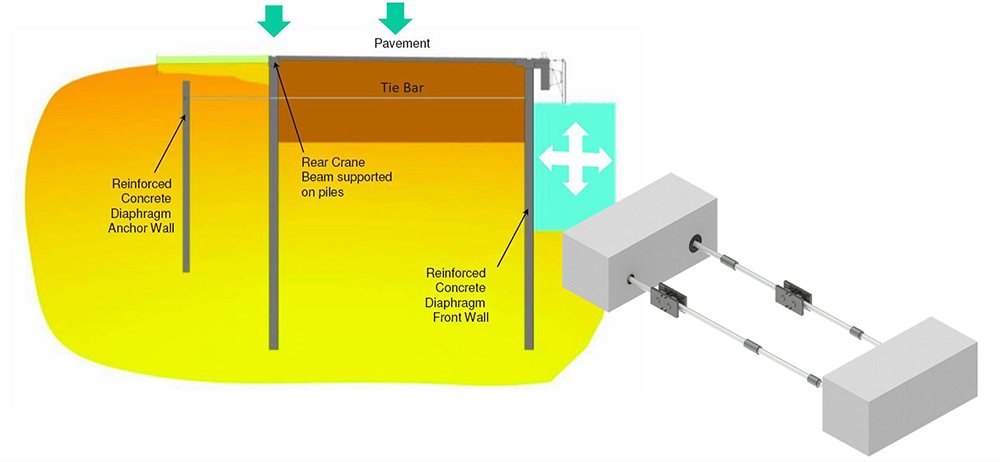

To support this pier expansion, Dextra partnered with contractor Andrade Gutierrez for the engineering and supply of Marine Tie Bars.

In 2014, Dextra supplied 100 tons of steel rods in medium diameters M56 and M59. The rods were anchored to the wall using swivel plates and nuts, allowing for 5° multidirectional adjustment.

These plates were positioned onto the waler beams, which were also supplied by Dextra. Waler beams are installed onto the sheet piles, and their design is directly influenced by the chosen Marine Tie Bars solution. For example, the spacing of the beams is impacted by the diameter of the bars and the angle of the rods.

Between the wall, Hinge couplers were installed in line to allow for additional vertical tolerance. This was necessary to counteract ground settlement, which can occur over time due to the heavy cranes operating and the piles of stored containers. The Hinge couplers provided the flexibility needed to accommodate any vertical movement and ensure the stability of the structure.