Nagpur Metro, Reach-1 (Line 1)

Nagpur, the second capital of Maharashtra and one of the fastest developing city in India is witnessing major growth in terms of Infrastructure. The development encompasses primarily the connectivity, of which Metro rail becomes a major part.

Incepted in 2016, the metro project is being a subject of acclaimed discussion for its speed of execution and the quality of construction.

Within the city boundaries, it requires the highest standards of safety considerations including the seismic analysis of structure in service life.

Project Requirement

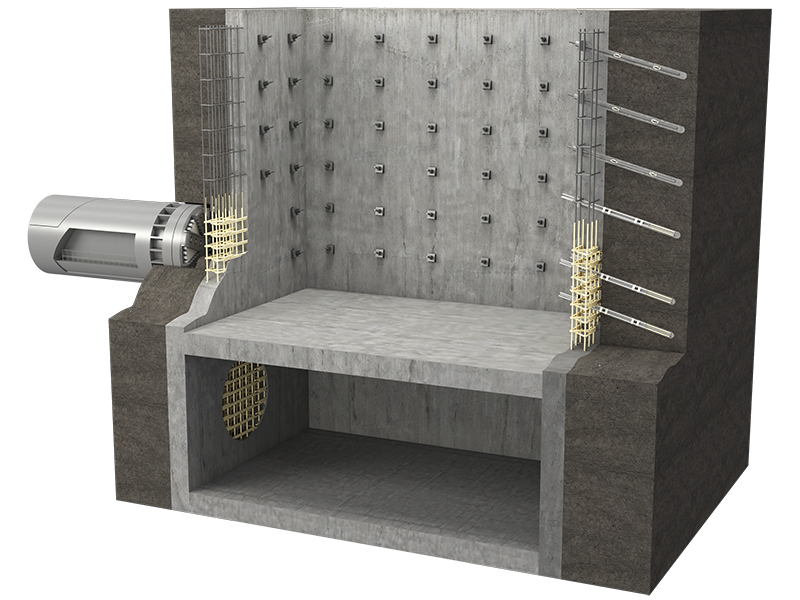

The fast track project has typical structure for its Line 1 alignment, where the viaducts are supporting 2 levels of pathways, lower one for NH-7 and upper one for the metro rail. As the impact loading is a big concern due to train movement.

Being the stretch of always busy traffic, a solution was required which does not have to revise the existing design. Plus a major concern was the impact on speed of the otherwise fast moving project. The issue was concerning to all the stakeholders especially the GC for the project, who were looking to maintain the agility as well as find a sustainable solution.

Solution

Dextra Introduced Shear Key Bars for the priority section allowing the structure to neutralize the seismic forces. This not only helped the contractor to get the work done faster, but also enabled the client to go for the trial run earlier than expected.