Rajasthan Atomic Power Project (RAPP) 7&8

The Rajasthan Atomic Power Project (RAPP) is a nuclear power plant in Rawatbhata, Rajasthan, India, with 6 pressurized heavy water reactor (PHWR) units and a total installed capacity of 1,180 MW.

The plant’s owner and operator, the Nuclear Power Corporation of India (NPCIL), is expanding the plant’s capacity by building 2 additional reactors, Units 7 and 8.

In July 2011, the first pour of concrete (FPC) for the 7th reactor, with a capacity of 700MW, was completed. The unit’s start-up transformer (SUT) was also commissioned.

The 8th reactor, which will similarly have a capacity of 700MW, is scheduled to be finished in December 2021.

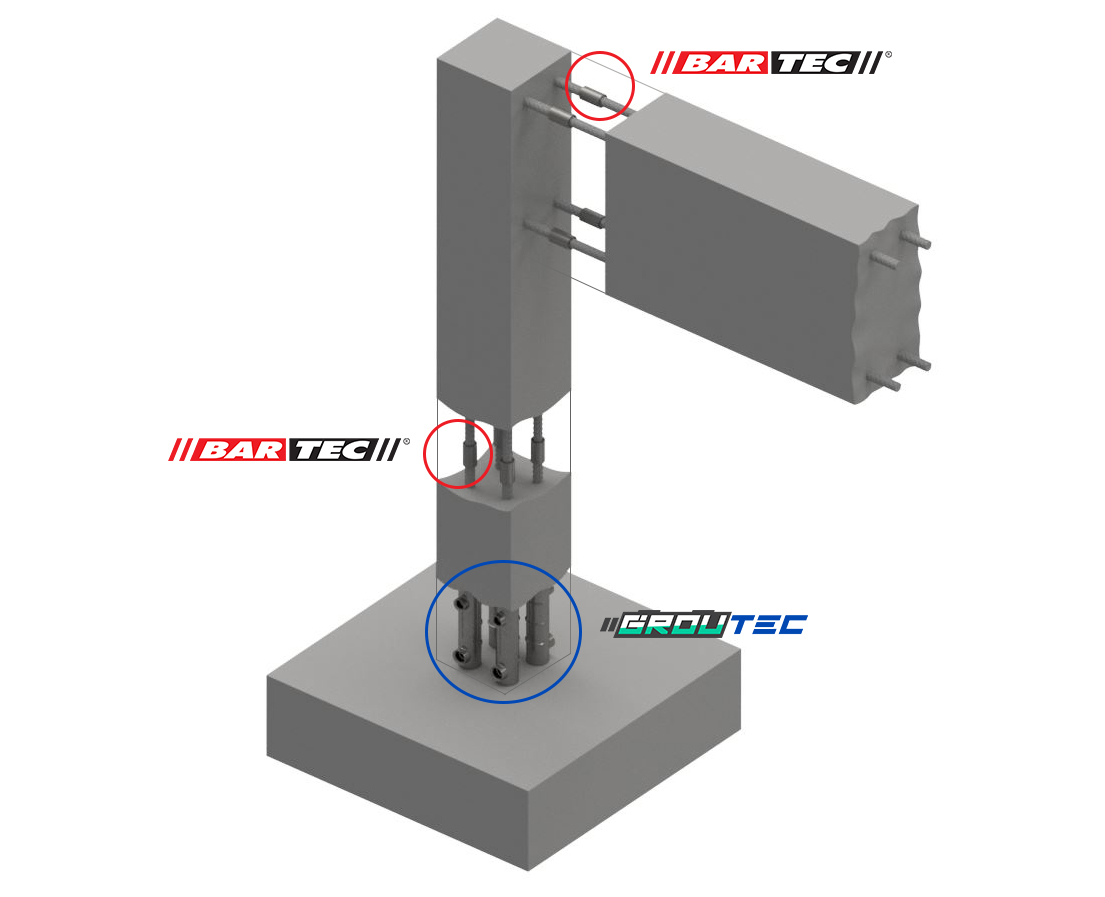

Dextra has supplied almost 500,000 Bartec couplers for the reinforcement of reactor buildings, auxiliary buildings, and spent fuel storages.

The 2 PHWR reactors will boost the plant’s existing capacity by 1,400MW, 700MW of which will be allocated to the state of Rajasthan.