New Bay Bridge of San Francisco

The New Bay Bridge was a large civil engineering project undertaken between 2002 and 2013. The aim of the project was to replace two segments of the Bay Bridge that were vulnerable to earthquakes with a new structure designed to withstand seismic forces.

For this project, Dextra was involved in two segments of the renovation: the approach to the Bay Bridge on the San Francisco side and the eastern segment from Yerba Buena Island to Oakland.

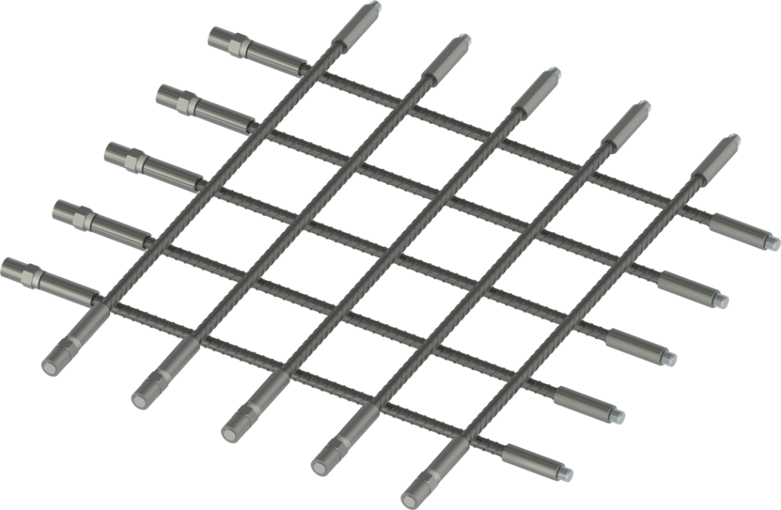

Dextra supplied its Bartec® Headed Bar systems for this project. Headed Bars feature an anchor disc mounted on the end of a rebar previously prepared for the Bartec® system.

The use of Headed Bars provides a smart and compact alternative to long rebar hooks in areas where reinforcement is particularly congested. Unlike hook bars, Headed Bars are easy to install, as end anchors can simply be screwed onto the reinforcement at a later stage, after the reinforcement is in place.

For the approach to the Bay Bridge in San Francisco and the eastern segment of Yerba Buena Island, Bartec® Headed Bars were used for shear reinforcement in the column foundations as well as in the bridge hinges.

The Bartec® Headed Bars solution is approved by Caltrans (the California Department of Transportation) for all imperial bar sizes #3 to #18 and is also certified by the ICC-ES.

female sleeves and

female sleeves and