Kakrapar Atomic Power Station 3&4

Kakrapar Atomic Power Station is a nuclear power station in India, which lies in the proximity of Surat and Tapi river in the state of Gujarat.

Unit 3&4 is India’s first pair of indigenously designed Pressurized Heavy Water Reactors (PHWRs) of 700 MW unit size located at Kakrapar in Gujarat, where two units of 220 MW PHWRs are already in operation.

The first concrete pour for Kakrapar 3 and 4 took place in November 2010 and March 2011 respectively, after Atomic Energy Regulatory Board (AERB) approval.

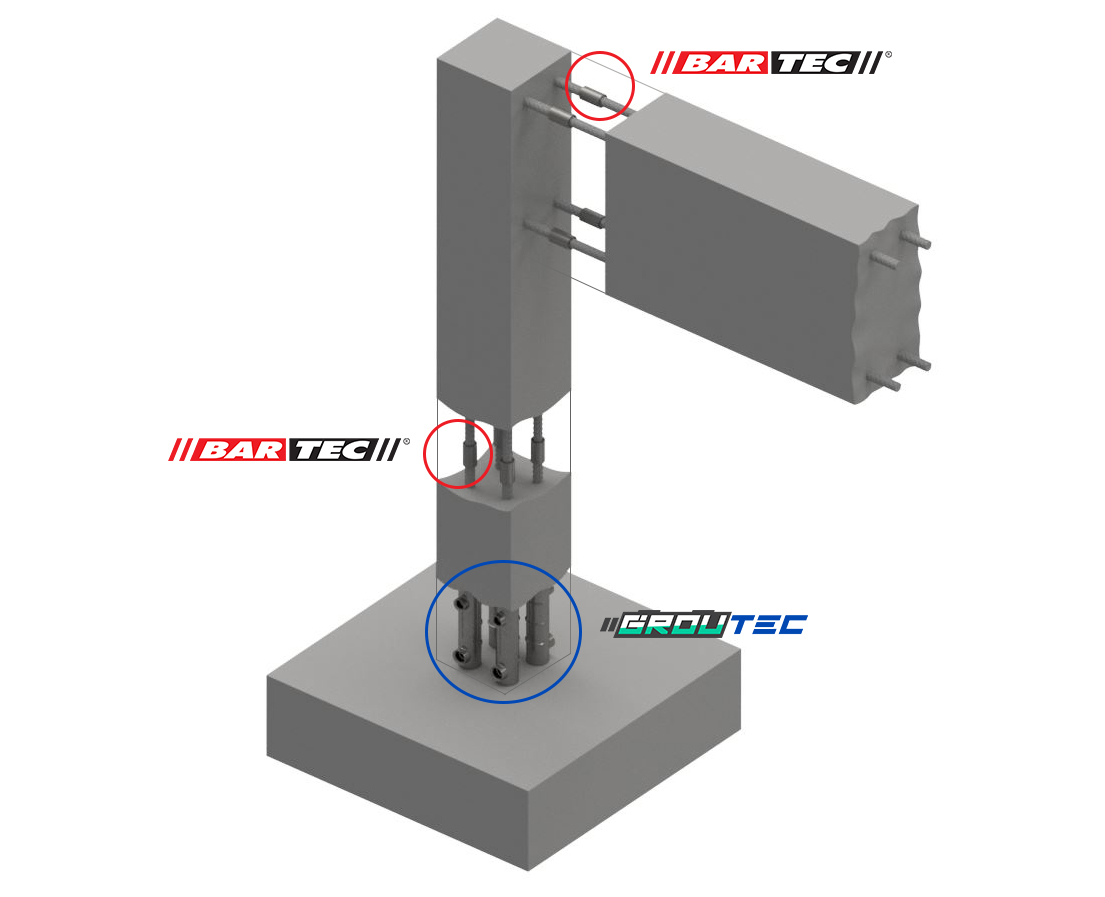

Since then, Dextra had supplied 540,000 Bartec rebar couplers, to connect slabs and columns of reactor and control buildings.

Moreover, Unitec bolted couplers were installed to connect rebars without the need of any thread preparation.

Finally, headed bars were mounted onto the reinforcement bar end, drastically reducing rebar congestion.

The commercial operation of Unit-3 is expected to be in March 2021 while its twin unit, Unit-4, is anticipated to start a year later.

Sources of images: https://en.wikipedia.org/wiki/Kakrapar_Atomic_Power_Station, https://www.nucnet.org/news/kakrapar-3-indigenous-phwr-achieves-first-criticality-7-3-2020, https://www.asiavillenews.com/article/a-look-at-the-kakrapar-3-reactor-54367