Olympic Velodrome

The Olympic Velodrome, now renamed as Lee Valley VeloPark, is a multipurpose sport facility located in East London. The facility was initially built to host the 2012 London Olympics and Paralympics. The facility still features road course tracks and BMX tracks and hosts international cycling competitions.

For this project, Dextra Europe delivered the Griptec rebar splicing solution to contractors Sir Robert Mcalpine and Byrne construction.

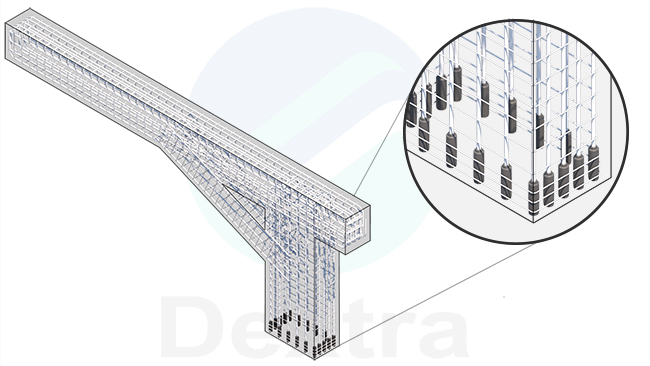

The Griptec splices were mostly use to provide vertical rebar connections in the velodrome columns.

Our Griptec solution was supported by Dextra’s local distributor in London which hosts the Dextra Griptec equipment required for the extrusion of the Griptec sleeves onto the rebar.

Griptec is a CARES TA1-A, TA1-B and TA1-C approved solution, making it suitable for even the most advanced rebar splicing applications and stringent project requirements.