Jeddah Tower, Saudi Arabia

Jeddah Tower (previously known as Kingdom Tower) is a landmark skyscraper located along the Red Sea, in northern Jeddah, Saudi Arabia.

Designed to surpass the 1-km mark for the first time in history, the tower is expected to reach a total height of 1,008 meters, making it the tallest building in the world.

Jeddah Tower will feature a 200-room Four Seasons hotel, serviced apartments, office spaces, and an observatory. A total of 59 elevators will transport visitors between floors.

The tower’s structural engineering is led by Thornton Tomasetti, while construction is managed by Saudi Binladin Group, to which Dextra is supplying products through its local partner, Bahra Steel.

Dextra is proud to supply 100% of the rebar couplers used in both the foundations and superstructure of the tower.

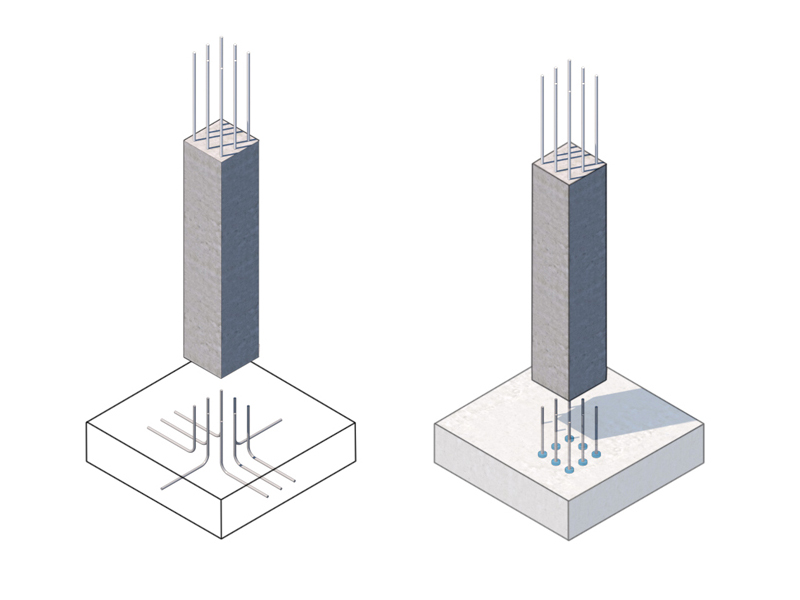

Two main types of rebar couplers are used in the construction:

- Standard Bartec couplers are used for all foundations, columns, and vertical connections, allowing for the fast assembly of prefabricated cages.

- Special bridging couplers are used for slab connections, enabling the secure connection of each U-shaped rebar leg to a column.