SeaWorld Abu Dhabi, UAE

SeaWorld Abu Dhabi is a marine life theme park and animal research, rescue, and rehabilitation center currently under construction. It is planned to open in 2023 on Yas Island in Abu Dhabi, United Arab Emirates.

It will be the first SeaWorld park outside the U.S., operating under a license from SeaWorld Parks & Entertainment. The Abu Dhabi-based company Miral is the owner and operator of the project.

Dextra has supplied 400,000 Bartec couplers for the connection and reinforcement of columns, beams, and slabs.

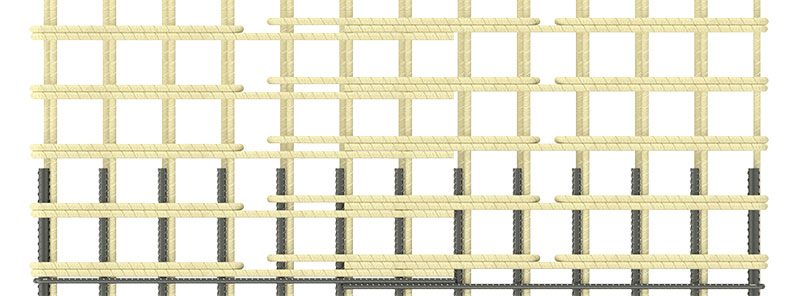

Moreover, 20,000 linear meters of cuttable GFRP (Glass Fibre Reinforced Polymer) rebar have been installed in the overlay slabs of the swimming pools, replacing steel rebars as the preferred choice.

Thanks to its durability and corrosion-free nature, GFRP is an ideal material for concrete structures exposed to water.

Source of images: https://www.constructionweekonline.com/projects-and-tenders/267779-construction-of-mirals-seaworld-abu-dhabi-hits-40-milestone, https://www.thenationalnews.com/lifestyle/things-to-do/2023/05/22/seaworld-abu-dhabi-opens-with-star-studded-event/