One Nine Elms: changing the skyline of London

One Nine Elms is a new mixed-use high-rise project in London, facing the Thames river.

This real estate venture will replace the 44-year-old Market Towers with a 56-storey skyscraper called City Tower and a 42-storeys called River Tower, 18 floors of which will be dedicated to a 173-rooms luxury hotel.

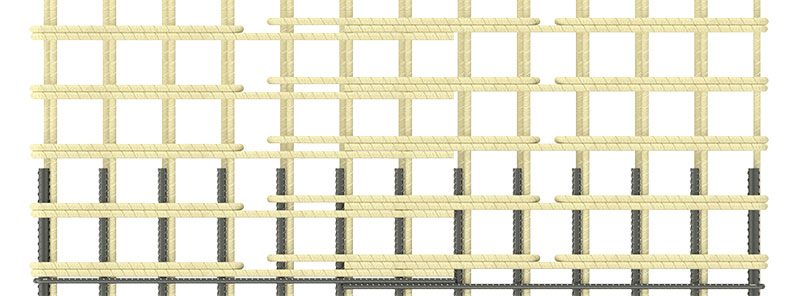

High performance rebar connectors are required in order to reinforce the structure of these two iconic towers: Dextra was entrusted with this job, and provided 70,000 Griptec couplers, well-known for their unrivaled performance in tension, compression, and fatigue conditions.

Supported by high-productivity rebar preparation equipment, Griptec couplers were installed in columns, beams, starter bars for slabs and other parts of the structure.

Furthermore, the homogeneity of concrete within the buildings’ bored piles was tested using the Cross Sonic Logging (CSL) methodology, requiring a transmitter and a receiver to be inserted in parallel water-filled tubes down the pile depth to measure the speed of ultrasonic pulses and ensure the integrity of the foundations.

Dextra’s SONITEC tube facilitated the test thanks to its easy installation into reinforcement cages: 4,000m of ST50 sonic tubes were provided for this project.

Upon completion, anticipated to be in 2022, the City Tower will become one of the tallest residential projects in London and the United Kingdom.