Dextra Group donated INR 15 Lakhs (20,000 US$), which was converted from the running distance of our charity virtual run event, to Dr. Sudin Gaikwad, the Deputy Secretary of the Maharashtra Chief Minister’s Relief Fund for COVID-19 in India.

Dextra Group | Reliable Connections

Dextra Group donated INR 15 Lakhs (20,000 US$), which was converted from the running distance of our charity virtual run event, to Dr. Sudin Gaikwad, the Deputy Secretary of the Maharashtra Chief Minister’s Relief Fund for COVID-19 in India.

Dextra rebar coupler systems are featured in the July 2021 issue of The Singapore Engineer magazine.

The article provides guidance on the use and advantages of the systems for infrastructure projects in Singapore, considering ISO 15835 standard requirements.

Read the article below:

For more information about our rebar couplers

Dextra Group had launched the first charity virtual run “Dextra Group Virtual Run & Walk 2021 (80-day challenge)” which is also the first employee engagement activity for all affiliates around the world.

The challenge started from April 19th until July 7th with 158 participants from 8 affiliates which included Dextra Asia, Dextra Industry & Transport, Dextra Manufacturing, Dextra China, Dextra Building Products (Guangdong), Dextra Middle East, Dextra Europe / Dextra Construction UK Limited, and Dextra Private India Limited.

During the 80-day challenge, the total distance we collected together was 18,825 km., with 2,789 activities. The most active team was Dextra team in China.

Every drop of sweat counts! Each kilometer was converted into USD and was going to be donated to the Chief Minister Relief Fund of Maharashtra state, a non-profit organization that supports those in need during the COVID-19 crisis in India.

Missed the live webinar? You can watch the recorded version now.

Dextra joined the Virtual Event : Energy – Construction – Infrastructure B2B Forum in ASEAN, organized by Franco-Thai Chamber of Commerce (FTCC) on May 20, 2021.

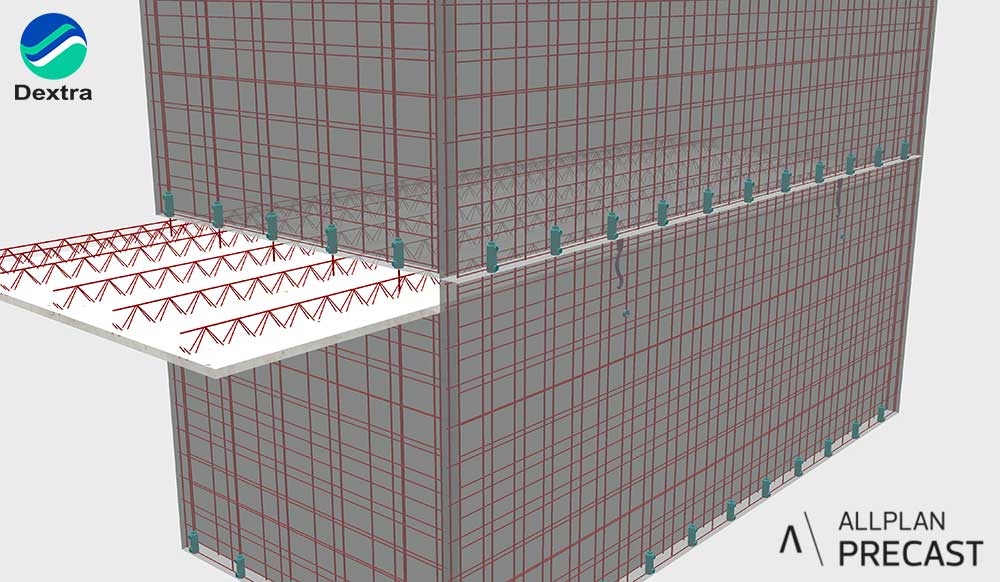

Our team members, Mr.Herve Lemoine, Managing Director and Philippe Neveu, Regional Sales Manager – SEA, were honored to have the opportunity to share some insights on the “Safe and Sustainable Technologies from Design to Construction” topic, focusing on “Design To Manufacture” solutions which are laying the ground for a dramatic increase in efficiency, sustainability and safety for the entire construction industry.

It was a pleasure to join this insightful event and discuss about the future of infrastructure construction in the ASEAN region.

The event was a success with more than 350 attendees from 7 ASEAN countries and France and Russia.

Watch the recording:

We are pleased to invite you to our live webinar on “Fiber Reinforced Polymer (FRP) Rebars for Permanent Applications”, presented by Pierre Hofmann, Geotechnical Product Line General Manager, Dextra China, on Wednesday, 9th June, 2021 from 2 to 3 p.m. (GMT+7).

The webinar will introduce the characteristics of FRP, key considerations in designing, applications for permanent use and economics comparison with conventional techniques.

FRP rebars are being used for various application, including precast building constructions, flatworks, marine structures, bridges and repair works.

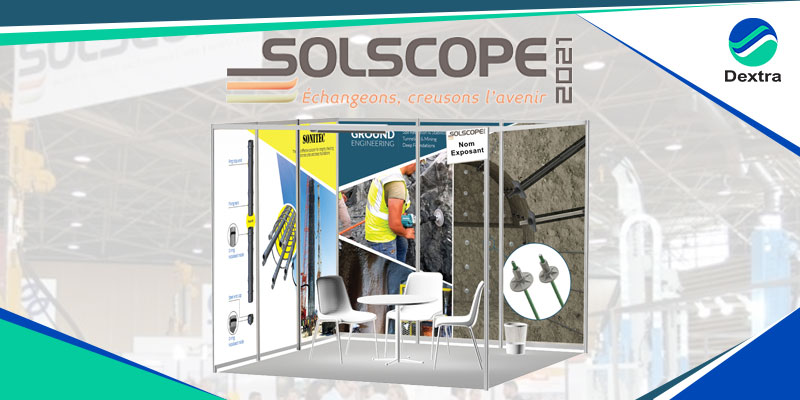

Dextra will be exhibiting at Solscope, an international exhibition for the geotechnical, drilling and special foundations sectors on 23rd and 24th June 2021.

Come and meet our specialists at booth number H2, Lyon Euroexpo, Lyon, France and discover a selection of our latest geotechnical solutions and projects.

A lightweight, easy-to-install tube systems for concrete integrity testing in foundations using the Crosshole Sonic Logging (CSL) test method.

A cut-able active anchor made of Glass Fiber Reinforced Polymer (GFRP) material, which is cut-able and can be excavated by any standard equipment.

High performance fiberglass and steel bolts covering all types of applications.

Visit RHE24 / DEXTRA booth at the Australasian Tunnelling Conference (ATS 2020+1) on May 10-13, 2021 at booth no. 57, Melbourne Convention & Exhibition Centre (MCEC), Australia.