第2回ホーチミン市環境衛生

The Second Ho Chi Minh City Environmental Sanitation Project consists of the construction of interceptor that will convey the wastewater collected from the Nhiêu Lộc-Thị Nghè Canal and District 2 areas of Ho Chi Minh City to the treatment plant.

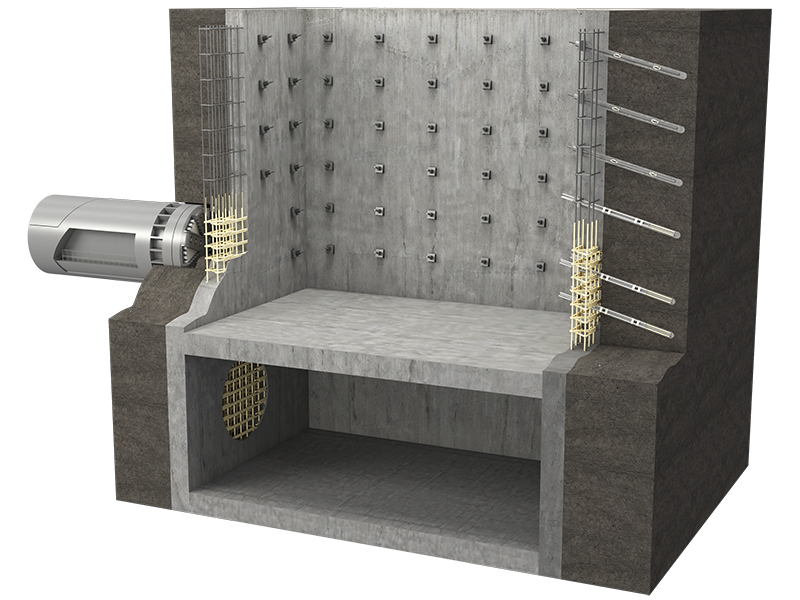

Dextra has been involved in the construction of the large underground system by supplying 40 Soft-Eyes to assist in the tunnel breakthroughs.

The cuttable Glass Fiber Reinforced Polymer (GFRP) Soft-Eyes were applied to reinforce 21 shafts, allowing the penetration by the Tunnel Boring Machine (TBM) without the need of removing steel reinforcement and without the risk to damage the TBM’s head.

With its completion, planned to be in 2022, the wastewater services in HCMC will have a considerably more sustainable nature, and will be remembered as the first big step toward the alleviation of the environmental and sanitation issues of the Country.