ラジャスタン原子力発電プロジェクト (RAPP) 7&8

ラジャスタン原子力発電プロジェクト (RAPP) は、インドのラジャスタン州ラワットバタにある原子力発電所で、6 基の加圧重水炉 (PHWR) ユニットと総設置容量 1,180 MW を備えています。

この発電所の所有者であり運営者であるインド原子力公社(NPCIL)は、7号機と8号機の2基の原子炉を追加建設することで発電所の生産能力を拡大している。

2011 年 7 月に、700MW の容量を持つ 7 番目の原子炉への最初のコンクリート (FPC) の注入が完了しました。ユニットの起動変圧器 (SUT) も試運転されました。

8号機も同様に出力700MWとなり、2021年12月に完成する予定だ。

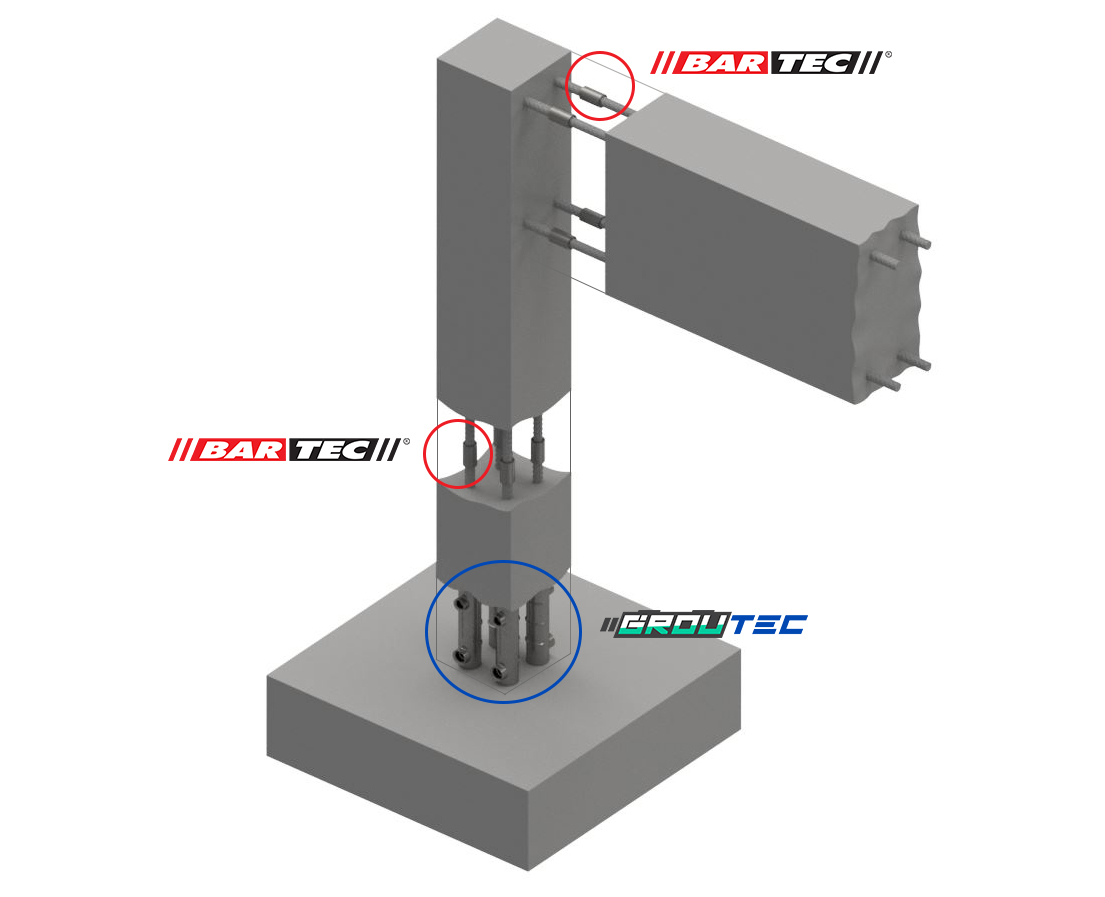

デクストラは約50万台を供給した バーテック 連結器 強化 原子炉建屋の 付属建物、使用済み燃料貯蔵庫など。

2基のPHWR原子炉により、同発電所の既存の発電能力は1,400MW増加し、そのうち700MWはラジャスタン州に割り当てられる。