The expansion project of the Lai King Building, established in 2001 at Princess Margaret Hospital in Hong Kong, aims to enhance ambulatory care services and ensure compliance with infection control and service standards in modern healthcare settings.

The project involves the demolition of the existing structure, construction of a new extension block, renovation and refurbishment of the existing building, construction of link bridges connecting the new extension block and the existing building, as well as external works and landscaping.

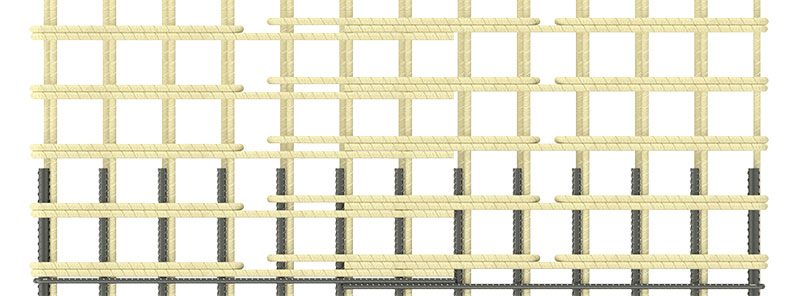

Dextra is actively involved in the site formation and foundation works, which commenced in August 2021. Our contribution includes supplying Astec GFRP (Glass Fiber Reinforced Polymer) soil nails with a diameter of 32 for temporary support during excavation. These soil nails are renowned for their lightweight composition, making them easier to handle and install. This characteristic significantly reduces labor requirements and construction time, thereby allowing for greater productivity on-site.

Furthermore, the GFRP material used in these soil nails exhibits high resistance to corrosion, distinguishing it from traditional steel soil nails. This attribute ensures the longevity and durability of the temporary support system, ultimately reducing the need for costly maintenance and replacements in the future.

The exceptional tensile strength of the GFRP soil nails plays a crucial role in effectively restraining the lateral displacement of the soil, thereby minimizing the risk of ground movement and potential collapse.

The construction works for the entire project are expected to be completed by 2026.