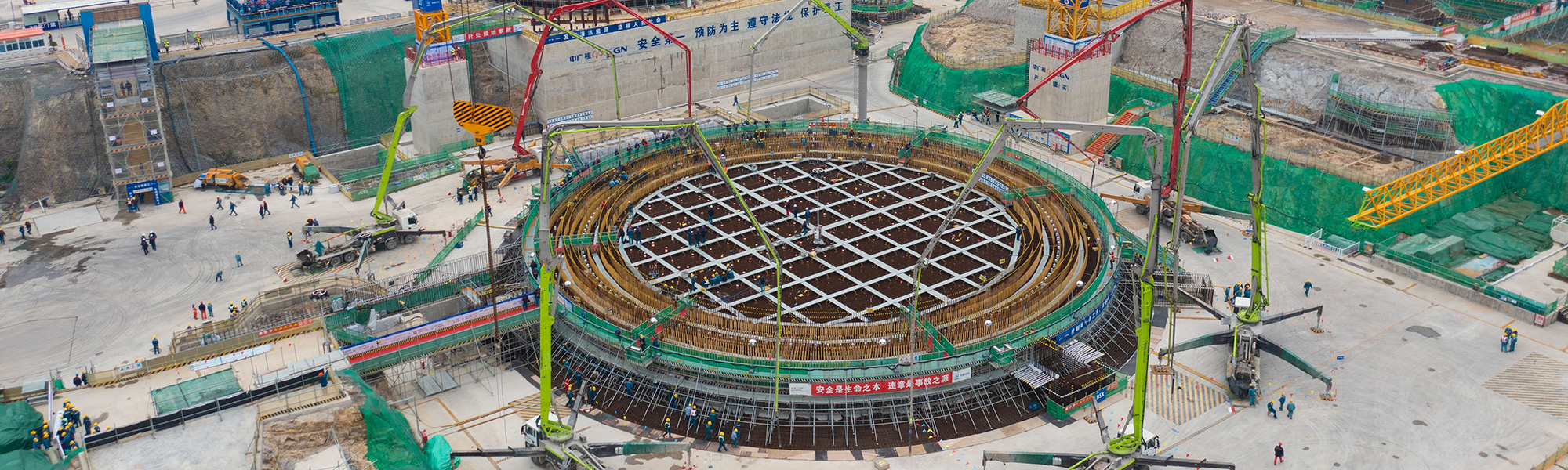

San’ao Nuclear Power Plant 1&2, China

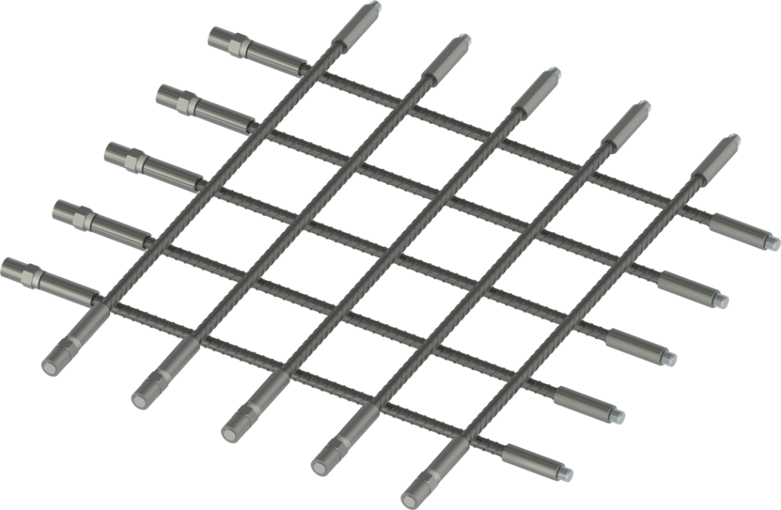

デクストラ has successfully supplied 340,000 グリップテック couplers for the aircraft impact-resistant shell construction of the San’ao Nuclear Power Plant units 1 and 2, featuring the advanced HPR1000 Hualong reactors.

グリップテック, recognized as the only 100% proof-tested splicing system, has gained the trust of over ten nuclear reactors globally, cementing its reputation for reliability and safety in high-stakes environments. The system’s stringent quality assurance processes ensure that each coupler meets the demanding standards required for nuclear applications, providing unparalleled performance and durability.

One of the standout features of グリップテック is its high-productivity bar end preparation equipment. This state-of-the-art machinery boasts an impressive processing speed of 30 to 45 seconds per bar end, significantly enhancing construction efficiency. Additionally, the equipment is designed for operation by a single operator, optimizing workforce utilization.

Moreover, デクストラ is the first manufacturer of civil construction products with an ISO19443 certified quality management system for nuclear safety. This certification underscores デクストラ‘s commitment to the highest standards of safety and quality in the nuclear industry, demonstrating the company’s commitment to excellence and reliability.

The San’ao Nuclear Power Plant project is a key component of China’s strategic initiative to expand its nuclear power capacity, which is vital for meeting the country’s growing energy needs while reducing carbon emissions. By supplying グリップテック couplers, デクストラ is playing a crucial role in ensuring the safety and efficiency of this project.

female sleeves そして

female sleeves そして