ケープタウン スタジアム

新しいグリーン ポイント スタジアムとしても知られるケープタウン スタジアムは、南アフリカのケープタウンにあるサッカーと多目的のスポーツ会場です。このスタジアムは、南アフリカが主催する 2010 FIFA ワールドカップに備えて、収容人数 18,000 の古いグリーン ポイント スタジアムを置き換え、収容人数 55,000 のより大きなアリーナを提供するために建設されました。古いアリーナは 2007 年に取り壊され、その後新しい会場の建設が行われ、ワールドカップの最初の試合の数か月前の 2009 年 12 月に完成しました。

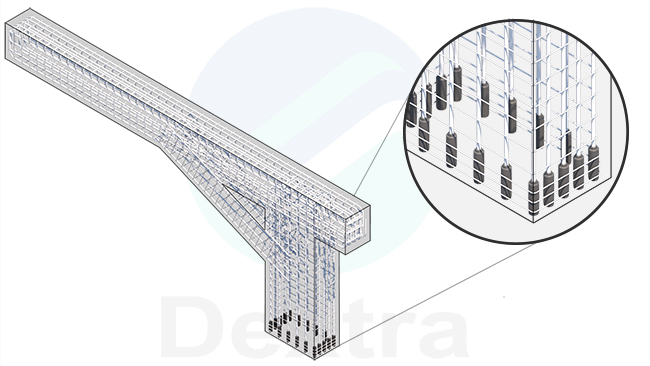

この大規模なスタジアム プロジェクトに、Dextra は Bartec 鉄筋カプラー ソリューションを提供しました。これは、南アフリカの Dextra が提供する主要な鉄筋カプラー ソリューションです。 Dextra のオファーには、70,000 個の高性能鉄筋カプラー、生産性の高い鉄筋準備装置、生産レベルとスケジュールを保証するためのすべての建設段階でのトレーニング/アフターサービスが含まれていました。

Bartec カプラーは、垂直コネクタとしてスタジアムの基礎と柱のバーを接続するために使用されました。

南アフリカでの鉄筋カプラーの入手可能性の詳細については、当社の問い合わせ先を参照してください。 パリオフィス