シーワールド・アブダビ(UAE)

シーワールド・アブダビは、現在建設中の海洋生物テーマパークであり、動物の研究、救助、リハビリテーションセンターです。アラブ首長国連邦アブダビのヤス島に2023年にオープン予定です。

これは米国外で初めてシーワールドパークとなり、シーワールド・パークス&エンターテインメントからのライセンスに基づいて運営されます。アブダビに拠点を置くミラル社がこのプロジェクトの所有者兼運営者です。

デクストラは40万台を供給した バーテック 柱、梁、スラブの接続および補強用のカプラー。

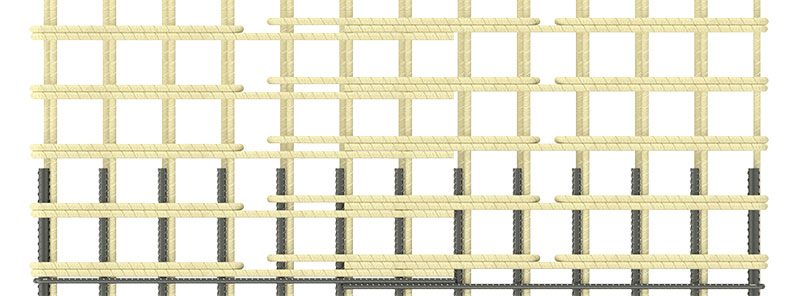

さらに、20,000メートルの切断可能な GFRP(ガラス繊維強化ポリマー)鉄筋 優先的な選択肢として、プールのオーバーレイ スラブに鉄筋の代わりに設置されました。

GFRP は耐久性があり腐食しない性質があるため、水にさらされるコンクリート構造物に最適な材料です。

画像出典:https://www.constructionweekonline.com/projects-and-tenders/267779-construction-of-mirals-seaworld-abu-dhabi-hits-40-milestone、https://www.thenationalnews.com/lifestyle/things-to-do/2023/05/22/seaworld-abu-dhabi-opens-with-star-studded-event/