鉄筋接合ソリューションと建設における課題への答え

建設業界は、多くのプレーヤーが参入し、常に進化を続ける分野です。鉄筋コンクリートにおける鉄筋の接合に使用される鉄筋メカニカルスプライスは、DEXTRAが1983年から確固たる地位を築いてきたニッチな分野です。私たちは、Dextra Europeのゼネラルマネージャーであるオリヴィエ・グルレ氏とコマーシャルディレクターのアントン・ジュラブレフ氏に話を伺いました。両氏に、鉄筋メカニカルスプライスというニッチ市場における課題についてお話を伺いました。

Dextraグループの歴史について教えていただけますか?

DEXTRAグループの設立は、1986年にブイグ・グループがSCREGグループを買収した際に、アジアの建設大手であるDRAGAGES & TRAVAUX PUBLICSを買収したことに遡ります。Dragages社は、東南アジアの拠点への供給を目的とした複数の商業子会社を有していました。香港における同社の事業は、現在も経営を担うフランス人起業家に引き継がれました。

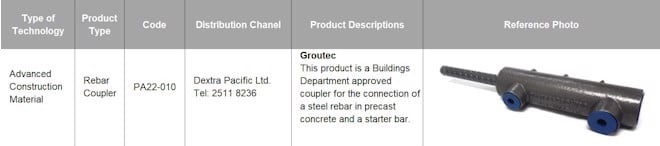

当初は単なる輸入業者兼サプライヤーであった DEXTRA は、すぐにお客様のニーズを満たす技術ソリューションの設計、製造、販売を行う企業となり、鉄筋の機械的接続システム (通称カプラー) の先駆者となりました。

このニッチ市場における当社の工業生産力と技術的専門知識は、グローバル展開を加速させてきました。しかしながら、DEXTRAは依然としてフランス株主が所有する中規模企業であり、建設分野に特化しています。グループの売上高は1兆4千億米ドル、従業員数は約900名、55カ国以上で事業を展開しています。

従来タイを拠点としていた生産拠点は、市場により近い地域へと拡大しました。事業は発展を続け、子会社のDEXTRA Europeを通じて、旧大陸における事業活動は現在、売上高の251億トン/トンを占めています。

35 年を超える経験を持つ DEXTRA は、現在、生産能力と事業展開国の多様性の点でこの市場のリーダーとなっています。

コンクリート中の鉄筋間の力の伝達は、従来、鉄筋を重ね合わせることで行われています。そのため、建設業界関係者にカプラーの使用に関する認識を高めることは大きな課題となっています。

建設業界には、実証済みの慣習があります。機械接合は、重ね継ぎに代わる代替手段として、現場での施工性を向上させるため、あるいはコンクリートの劣化時に構造性能を向上させるために用いられます。

実際、重ね継ぎの場合、鉄筋間の力の伝達を確実にするのはコンクリートの健全性です。コンクリートが損傷(鉄筋の腐食、爆発、地震による剥離など)すると、力の伝達が確保されなくなり、構造物の安定性が危うくなります。

バリューチェーンのあらゆるレベルで現場で行われるべき認識は非常に大きく、エンジニアリング学校から設計事務所、そしてエンドユーザーまで浸透させる必要があります。

建設のニーズは、建設する建物の種類によって異なります。どのように提案内容を調整していますか?

まず、要求される性能に応じて、建物の要件は原子力発電所の要件よりも低くなります。地震帯など、環境も要件に影響を与える可能性があります。そのため、当社はこれらのタイプそれぞれに適応できる多様なソリューションを提供しています。現在、当社は、高層ビル、地下鉄、空港、港湾、フェカンの風力発電所、そして要求レベルが最も高い原子力発電所(フラマンヴィル、ヒンクリー、ロスアトムなど)など、幅広いプロジェクトにカプラーを供給しています。

現場施工のニーズは、用途に応じて、補修やプレファブリケーションのニーズとは異なります。それぞれの用途には異なるソリューション、つまりカプラが使用されます。ここでも、私たちはそれぞれに特化したソリューションを開発しており、今日ではこれらすべてのニーズに応える非常に多様な製品ラインナップを取り揃えています。

DEXTRA Europe は、新たな制約に基づいて絶えず変化するパフォーマンスとアプリケーション要件の課題にどのように適応しているのでしょうか?

建設業界は変化を続けています。近年、構造疲労や耐震性に関して、より厳しい要件が求められています。こうした状況に対応するため、当社のカプラに対する追加試験を実施し、場合によっては既存のソリューションを改良する必要がありました。

さらに、用途面では、プレファブリケーションやモジュール化に目を向ける建築家や建設会社が増えています。こうした新たなニーズに応えるため、当社は現場での施工を簡素化するセメントグラウトカプラーシステムを開発しました。

DEXTRA Europe は認証の問題にどのように取り組んでいますか?

建設市場は非常に標準化されている一方で、各国の固有の特性も大きく残っています。ユーロコードは規格の調和化に向けた大きな前進ですが、依然として各国の付属書や現地の認証機関が存在し、製品の流通を複雑化させています。

例えばフランスでは、あらゆるスプライシングシステムはAFCABの認証を受ける必要があります。ヨーロッパでは、時間と費用のかかる認証制度が蔓延しているため、たとえ製品が要求される要件を満たしていたとしても、選択を迫られることになります。

提案されたソリューションの技術的検証を維持することは明らかに重要ですが、欧州レベルでの調整の欠如は、最終的には各市場での使用の可能性を阻むことになります。

このカプラ市場の発展についてどのようにお考えですか?

現在、さまざまな生産者がそれぞれの市場の発展に関する数字を共有していないため、この市場の成長の有無について正確な見通しを描くことは困難です。

Dextraに関しては、近年販売数が急増しており、2021年には世界中で1,500万個以上のカプラが販売されました。これは、当社の見解では、市場シェアの拡大と市場全体の成長に相当します。

全体的に、各市場の重要性は建設市場の規模と一致しており、ヨーロッパでは英国、ドイツ、フランスがトップ 3 を占めています。

DEXTRA グループが提唱する価値観とは何ですか?

当社の価値観は、顧客満足、誠実さと透明性、創造性と柔軟性、そして説明責任です。

これを実現するために、当社は設計から現場での使用まですべての段階を管理することに尽力しています。

当社は自社工場で生産することにより、製品の品質と納期を管理しています。

当社の工場には、材料と製造をより適切に管理するための独自の試験室が備えられています。

当社はバーの製造に必要な機器を自社で設計・製造しています。

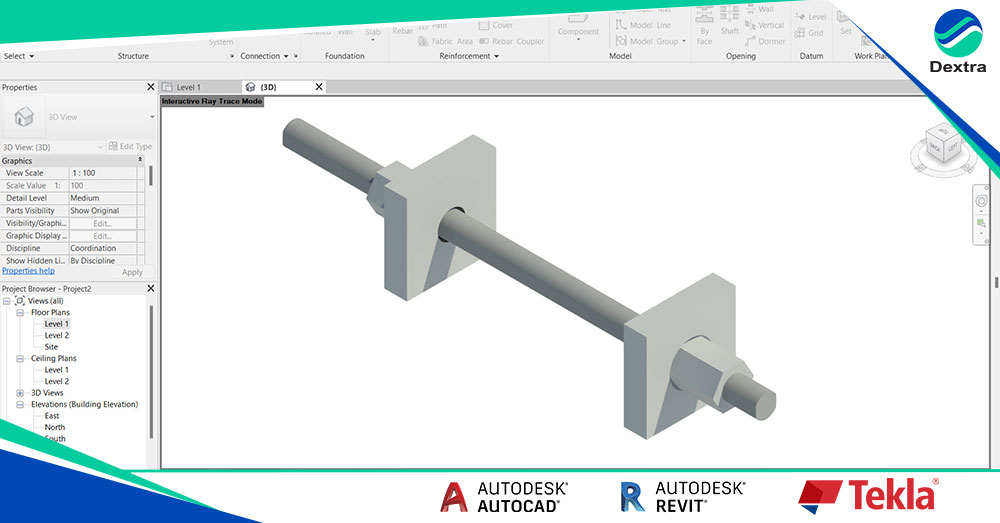

当社のエンジニアは、子会社やネットワークを通じて物理的にサポートを提供するだけでなく、リモート サービス テクノロジーを継続的に開発することで、クライアントとユーザーへの継続的なサポートを維持しています。

この事業において、これほど完全なバリューチェーンを構築しているのは当社だけです。

当社の研究開発チームは、市場の発展と技術的制約をサポートし、お客様の期待に可能な限り沿うように、ソリューションを常に検討しています。

たとえば、当社は自動パフォーマンス監視装置を組み込んだバーエンド準備装置を発明しました。この装置は、世界中のどこでも、わずかな不適合に対しても警告を発する機能を持っています。

Dextra は、図面や技術的な問題を理解できる土木技術者を中心としたエンジニアを擁しており、パートナーや建設会社に専門的な視点を提供できることから、ますます人気が高まっているコンサルティング業務も遂行しています。

(本コンテンツはSCRIBEOで制作しました。BFMBUSINESS編集部は本コンテンツの制作には関与しておりません。)

コンテンツをフランス語で読む