カテゴリー: ニュース

持続可能性を推進: 船舶用タイバー向け EPD を導入

デキストラ グループが従業員エクスペリエンス アワード タイ 2024 で受賞!

インドのプネーにあるデクストラの新工場を公開

デキストラは香港で創立 40 周年を祝います

デキストラはインドのムンバイで創業 40 周年を祝います

デクストラは中国での創業40周年を祝う

プレキャストオーバーヘッドタンク: 「Har Ghar Jal」を確保するための貯水革命

オーストラリアのSilva Globalとの新たな戦略的パートナーシップ

より強い未来の構築: Dextra Group と Silva Global が提携し、オーストラリアのインフラストラクチャーおよび建築部門のビジネスを推進

顧客エクスペリエンスの向上と独自のソリューションの提供を目的とした戦略的取り組みの一環として、エンジニアリング ソリューションの世界的リーダーであるデエクストラ グループは、オーストラリアの有力な現地販売代理店およびソリューション プロバイダーであるシルバ グローバルとの提携を発表しました。今年創立40周年を迎えるDextra Groupにとって、このコラボレーションは重要なマイルストーンとなる。この提携は特にオーストラリアのインフラおよび建築分野に焦点を当て、Dextra Groupのエンジニアリング専門知識とSilva Globalの現地市場の要件に対する深い理解と対応力を結集します。

ローカル パートナーの利点: 比類のない専門知識を前面に押し出す

Silva Global の現地での強い存在感とオーストラリア市場に関する広範な知識は、パートナーシップの成功において極めて重要な役割を果たします。この提携は、Silva の迅速かつ効率的な対応能力を活用し、業界の厳しい要件を満たす迅速なサービスの提供を保証することを目的としています。さらに、Silva Global の包括的な在庫在庫により、製品への迅速なアクセスが可能になり、リードタイムが最小限に抑えられ、プロジェクトをタイムリーに完了することが保証されます。さらに、このパートナーシップにはバリューエンジニアリングの原則が組み込まれており、インフラストラクチャおよび建築分野のクライアントの特定のニーズに合わせた費用対効果の高いソリューションを提供します。

パフォーマンスを向上させる最先端の製品ソリューション

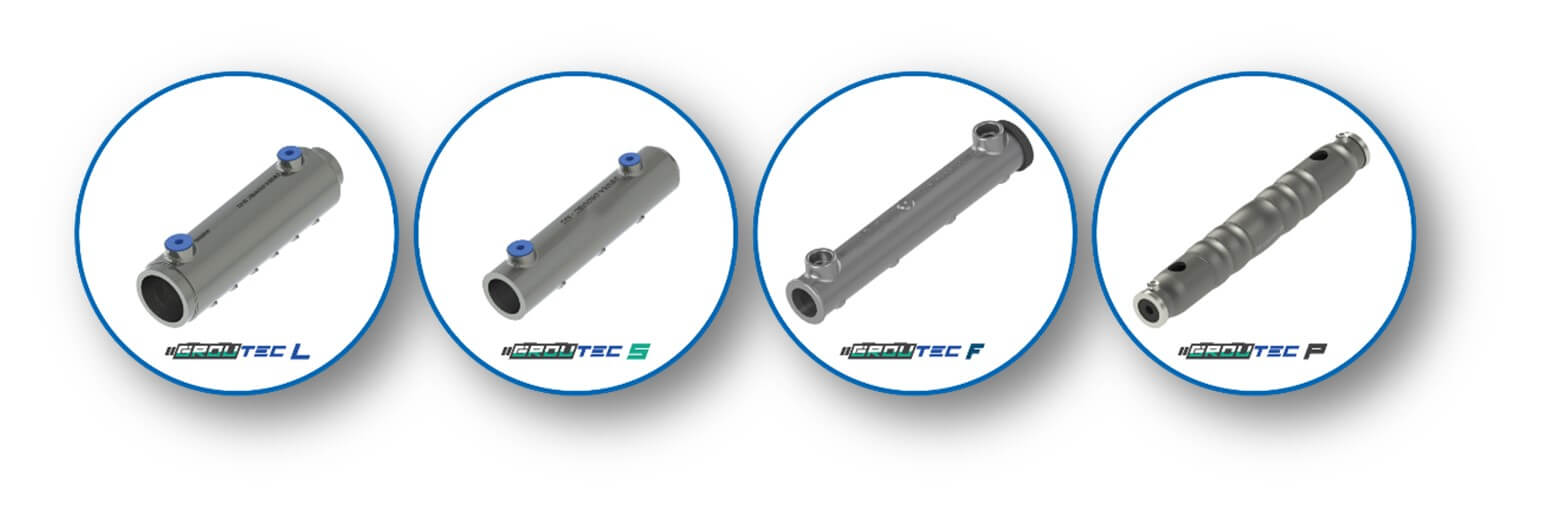

コラボレーションの一環として、シルバ・グローバルはオーストラリアのソリューション・プロバイダー・パートナーとして機能し、メカニカル・スプライス・システム、GriptecおよびGroutecカプラー、ならびにポストテンションおよび建築バー・システムなどのDextraの構造バー製品群を現地市場に導入します。 。原子力用途で知られるグリップテックはコンクリート接合部の構造的完全性を確保し、一方、グルーテックはプレキャスト用途向けに信頼性と耐久性のあるソリューションを提供します。これらの革新的な製品により、オーストラリアのクライアントはプロジェクトの品質、効率、持続可能性を向上させ、業界の進歩の最前線に立つことができます。

顧客重視の卓越性: 成功を後押しする

Dextra Group と Silva Global は、顧客満足への共通の取り組みにより、優れたサービス、迅速な支援、技術的専門知識を優先しています。この提携により、高品質製品の堅牢な在庫を維持することでクライアントのアクセスが向上し、プロジェクトに必要な資材に迅速かつ確実にアクセスできるようになります。 Dextra Group と Silva Global は、個別の対応とカスタマイズされたソリューションを通じて、クライアントが効率的かつ効果的に目標を達成できるように支援することを目指しています。

クライアントと関係者にとってのメリット: 優れた結果の提供

Dextra Group と Silva Global のコラボレーションにより、クライアントはプロジェクトを変革する最先端のテクノロジーと革新的なソリューションへのアクセスを提供します。 Dextra Group の高品質な製品ポートフォリオと Silva Global の現地での存在感と技術力を活用することで、クライアントは環境フットプリントを最小限に抑えながらプロジェクトの目標をより迅速に達成できます。このパートナーシップにより、プロジェクト管理も合理化され、スムーズな実行、コスト管理、タイムリーな納品が保証されます。クライアントは、期待を超え、優れた結果をもたらす包括的かつ統合されたアプローチを期待できます。

オーストラリアのインフラストラクチャーと建築部門が進化し続ける中、Dextra Group と Silva Global のパートナーシップは、進歩を推進し、持続可能な成長を促進する上で重要な役割を果たす態勢が整っています。卓越性への共通のビジョンと顧客満足への取り組みにより、この提携は高度なソリューション、効率的なサービス、画期的な製品を提供することで業界を再構築します。

デクストラグループについて:

Dextra Group は、エンジニアリング ソリューションの有名な世界的リーダーであり、最先端のテクノロジーと革新的な製品をさまざまな業界に提供しています。 40 年にわたる誇り高き伝統を持つ Dextra Group は、持続可能性をすべての活動の中心に置きながら、あらゆる取り組みにおいて卓越した価値と卓越性を提供することに尽力しています。

シルバ・グローバルについて:

Silva Global は、建設業界への材料と製品の供給を専門とする信頼できる現地代理店です。広範なネットワークとオーストラリア市場への深い理解により、Silva Global は迅速なサービスと優れたソリューションを全国の顧客に提供します。

デキストラは広州で創業40周年を祝う

中国広州での創立 40 周年記念式典にご参加いただいた尊敬するパートナーの皆様に、心より感謝申し上げます。

2023 年 6 月 15 日、当社は中国の大切なパートナーとともに 40 年間にわたるイノベーションと成功を祝いました。ゲストの皆様は、工場見学、カクテルランチ、革新的な最新情報、ガラディナーを含む特別なお祝いを楽しみました。それは、私たちが共有した成果に対する喜び、友情、そして感謝に満ちた忘れられない集まりでした。

皆様の存在とサポートにより、このマイルストーンはさらに有意義なものとなりました。私たちは、長年にわたり共に築き上げてきた並外れたパートナーシップに心から感謝しています。

広州での創立40周年記念式典で私たちが共有した忘れられない瞬間を垣間見てみましょう。一緒に魔法を追体験し、私たちの素晴らしいパートナーシップを祝いましょう!