Landmark 81 rises above Ho Chi Minh City’s skyline

81-storeys tower to become the 11th tallest skyscraper in the world

Landmark 81 is a high-rise tower project located on the bank of the Saigon river in Ho Chi Minh City’s Bing Thang. The project is owned and developed by Vietnamese Vincom Group.

Landmark 81 is a high-rise tower project located on the bank of the Saigon river in Ho Chi Minh City’s Bing Thang. The project is owned and developed by Vietnamese Vincom Group.

The tower, whose construction started end of 2014, is expected to reach a height of 461 meters, thus becoming the highest building in Vietnam and 11th tallest tower building in the world.

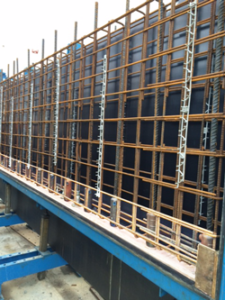

For Landmark 81, Dextra is supplying its Bartec® coupler system to contractor Coteccons. Bartec® system has been approved by  MACE International, owner’s representative, and ARUP, structural consultant on the project.

MACE International, owner’s representative, and ARUP, structural consultant on the project.

In total, 250,000 Bartec® couplers are being used for vertical rebar connection in the core wall and columns as well as for horizontal applications such as core wall-to-beam and core wall-to-slab connections.

The use of Bartec® rebar couplers allows the climbing formwork to move up without disturbance from protruding bars as well as connect the starter bars of the slabs in a very productive manner. These techniques, combined with state-of-the-art concrete monitoring, allow very fast construction cycles as short as 35 hours per floor.

techniques, combined with state-of-the-art concrete monitoring, allow very fast construction cycles as short as 35 hours per floor.

For the connection of steel columns to concrete beams, Dextra supplied 20,000 weldable couplers.

The construction is supported on site by three sets of Dextra Bartec® equipment which are being maintained by Dextra and operated by Dextra’s distributor in Vietnam, Lotus Greentech.

The construction has now passed level 35 (of 81) and will be completed in 2018.

Rolltec Stainless couplers for the new iconic Champlain Bridge in Montreal

3-km-long bridge spans over the Saint Laurence river

Reinforcing highway girders with post-tensioning bar systems

New highway north of Bangkok takes advantage of Dextra PT systems

Post Tensioning Bar systems are highly customizable and versatile solutions allowing for multiple applications in bridge/viaduct construction.

Post Tensioning Bar systems are highly customizable and versatile solutions allowing for multiple applications in bridge/viaduct construction.

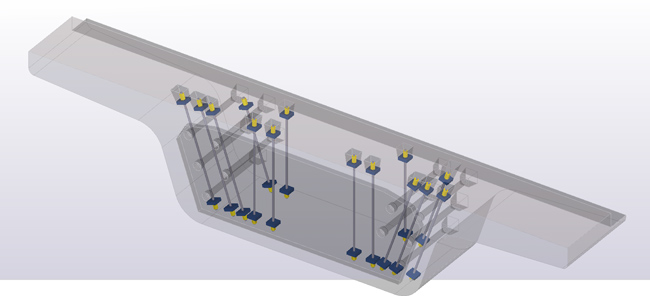

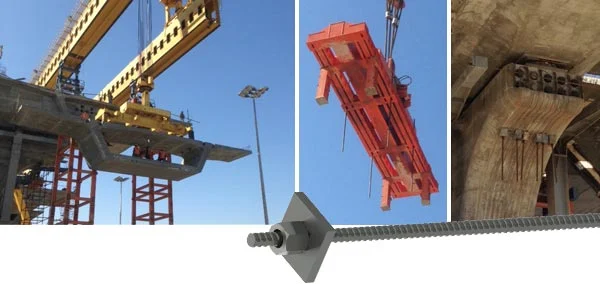

Dextra has recently supplied customized PT systems to Thai contractor Highcrete. These are used to reinforce the precast girder segments used on the Bang Pa In – Saraburi – Nakhon Ratchasima highway in the North-East of Bangkok.

The PT systems, made of hot rolled deformed high-tensile bars (FT bars) Ø36mm, allow for the vertical reinforcement of the precast  segments, with up to 14 sets per girder element.

segments, with up to 14 sets per girder element.

Each bar will be jacked and put under the required tension from the top of each element while on the ground. After that the girder is lifted and installed in its final position.

Permanent corrosion protection will be achieved by filling a galvanized duct around the bar with grout.

न्यू अल्जीयर्स ग्रांडे मस्जिद

The dome structure relies on Dextra Tension Bars for cross-bracing

The new Djamaa El Djazair Mosque of Algiers is a huge construction project located in the eastern part of the capital city of Algeria. It will feature the world’s tallest minaret with a height of 265m.

The new Djamaa El Djazair Mosque of Algiers is a huge construction project located in the eastern part of the capital city of Algeria. It will feature the world’s tallest minaret with a height of 265m.

Further to this, the large complex will be able to accommodate as many as 120,000 worshippers.

Dextra supplied more than 800 structural tension bar assemblies with diameters ranging from M16 to M56 to China State Construction Engineering Corporation, the main contractor.

These  are used for the cross-bracing of the roofing structure of the domed prayer room.

are used for the cross-bracing of the roofing structure of the domed prayer room.

Each tension rod is painted in white to match the interior design of the mosque. Bracing discs (top left picture) add to the special architectonic finish of the structure.

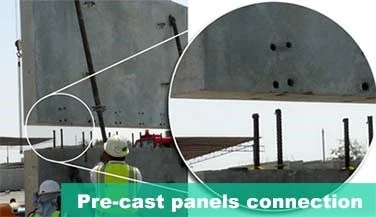

Precast construction > new Groutec एस range

Compact shape version fits even thin precast elements

Dextra has expanded the range of Groutec, its rebar splice designed for the quick and easy connection of precast elements.

The new Groutec एस (“Slim”) features a narrower body that makes it apt for use even in very thin precast panels, walls or columns. Thanks to its compact design, Groutec एस also allows extra savings on grouting mortar, making its use even more economical.

For contractors that need to work with larger tolerances, the Groutec standard range, rebranded as Groutec L, remains available.

Connecting wall panels in precast residential construction

Dextra offered Groutec to the Plum condominium in Bangkok

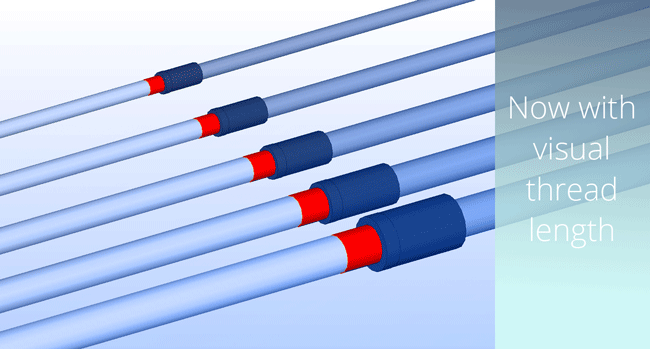

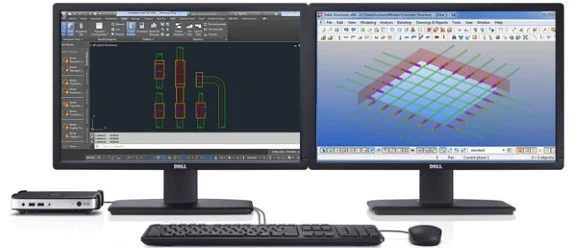

Rebar coupler attributes upgraded for Tekla 2017

Better visual identification of bars with threaded ends now possible

Dextra recently issued a new release of all its rebar coupler tools to upgrade to the latest version of Tekla.

Dextra recently issued a new release of all its rebar coupler tools to upgrade to the latest version of Tekla.

The new Tekla version allows a clear visualization of threaded bar ends, making it possible to see for example the extended threads on position splices.

Tekla attributes are available for download from Dextra website.

Team site visit at Bangkok International Airport

New Dextra team members visited the new satellite terminal site in June

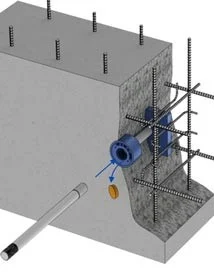

Bottom left >> Bar ends threaded with Bartec® system and protected by caps.

Bottom right >> Protruding part of D-Wall, with Bartec®, couplers for horizontal connections.

There is nothing like a field trip to a construction site, especially when it leads to a new terminal of one of the biggest aviation hubs in Asia!

Many thanks to contractor ITD for welcoming a delegation of new Dextra team members and showing them around Suvarnabhumi’s new satellite terminal site: a great opportunity to witness Bartec® coupler applications and threading operations in real site conditions.

New www.dextragroup.com website!

Discover our new website with more than 70 references!

of both towers) with its Bartec rebar

of both towers) with its Bartec rebar  In total, more than 800,000 Bartec rebar couplers and 20,000 Bartec

In total, more than 800,000 Bartec rebar couplers and 20,000 Bartec

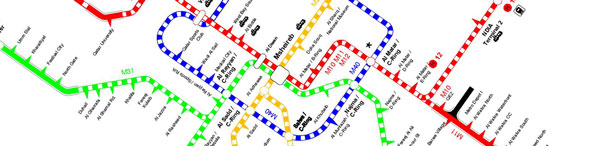

ve urban transit system project under construction in the capital of Saudi Arabia

ve urban transit system project under construction in the capital of Saudi Arabia

On the French island of La Réunion (located 700 km East off the coast of Madagascar), a joint venture composed of contractors VINCI Construction Grands Projets, Bouygues Travaux Publics, Dodin Campenon Bernard and Demathieu Bard, is currently building a new offshore elevated 2×2-lanes viaduct of 13 kilometers, which aims to replace the older unsafe road structure, located along the coast and frequently damaged by rockfall.

On the French island of La Réunion (located 700 km East off the coast of Madagascar), a joint venture composed of contractors VINCI Construction Grands Projets, Bouygues Travaux Publics, Dodin Campenon Bernard and Demathieu Bard, is currently building a new offshore elevated 2×2-lanes viaduct of 13 kilometers, which aims to replace the older unsafe road structure, located along the coast and frequently damaged by rockfall. to position, lift and sink heavy precast bridge piles – an engineering challenge considering the individual weight of the elements: up to 4,800 tons for the base of piles!

to position, lift and sink heavy precast bridge piles – an engineering challenge considering the individual weight of the elements: up to 4,800 tons for the base of piles!

Once the base reaches its final location, the top part of the anchorage is dismantled by divers so it can be reused for the installation of other piles.

Once the base reaches its final location, the top part of the anchorage is dismantled by divers so it can be reused for the installation of other piles. Bangkok’s MahaNakhon tower, the highest residential tower of Asia and the highest tower in Thailand (314 meters), was inaugurated at the end of August with a spectacular light show!

Bangkok’s MahaNakhon tower, the highest residential tower of Asia and the highest tower in Thailand (314 meters), was inaugurated at the end of August with a spectacular light show!

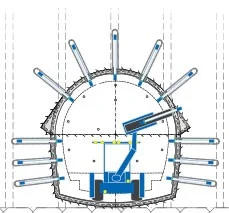

ASTEC Active Anchors have been installed by Franki Foundations & Atlas Foundations for stabilizing excavation works of the Bagneux station (Metro M4 extension and future M15), in the North of Paris. The solution has been approved for this project by engineering consulting firm SYSTRA.

ASTEC Active Anchors have been installed by Franki Foundations & Atlas Foundations for stabilizing excavation works of the Bagneux station (Metro M4 extension and future M15), in the North of Paris. The solution has been approved for this project by engineering consulting firm SYSTRA.

Dream Acres is a large residential complex (330,000 sq. m. area) located east of Bangalore in India.

Dream Acres is a large residential complex (330,000 sq. m. area) located east of Bangalore in India. Groutec couplers advantageously splice load-bearing elements together, ensuring a high performance connection and speeding up installation compared to more traditional wet in-situ joint methods.

Groutec couplers advantageously splice load-bearing elements together, ensuring a high performance connection and speeding up installation compared to more traditional wet in-situ joint methods. Congratulations to developer Sobha Ltd. for already completing the first towers ahead of schedule.

Congratulations to developer Sobha Ltd. for already completing the first towers ahead of schedule.

67 runners from Dextra’s Bangkok Factory and Headquarter office have joined a charity run in favor of the Thai Liver Association on Sunday 9th of October.

67 runners from Dextra’s Bangkok Factory and Headquarter office have joined a charity run in favor of the Thai Liver Association on Sunday 9th of October. for completing this challenge and successfully raising awareness and donations for the Thai Liver Foundation.

for completing this challenge and successfully raising awareness and donations for the Thai Liver Foundation.

Doha Link is a 12.4km project connecting Kuwait City (from Shuwaikh Port) to Doha Area. It will ultimately solve traffic congestion and offer a direct itinerary between the two areas thanks to a 7.7km bridge built on shallow waters across the Kuwait Bay.

Two different Dextra solutions are currently used for the

Doha Link is a 12.4km project connecting Kuwait City (from Shuwaikh Port) to Doha Area. It will ultimately solve traffic congestion and offer a direct itinerary between the two areas thanks to a 7.7km bridge built on shallow waters across the Kuwait Bay.

Two different Dextra solutions are currently used for the  Dextra’s new model of thread-rolling equipment for rebar end preparation is now available.

Dextra’s new model of thread-rolling equipment for rebar end preparation is now available.

The Dextra tension bar range for architectural applications is designed with flexibility in mind so designers can fully express their creativity. No other range on the market offers such a large selection of diameters, accessories and finishes. It’s all about finding the right combination to match your design.

The Dextra tension bar range for architectural applications is designed with flexibility in mind so designers can fully express their creativity. No other range on the market offers such a large selection of diameters, accessories and finishes. It’s all about finding the right combination to match your design.

The tower which will soon become the highest building in the world is currently being built in Saudi Arabia.

The tower which will soon become the highest building in the world is currently being built in Saudi Arabia.

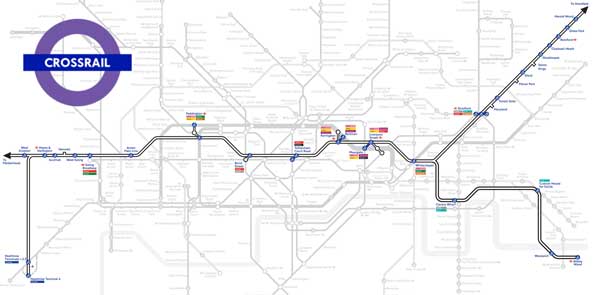

Expansion of Line 14 is part of the Grand Paris Express urban transportation plan. The fast subway line’s expansion will soon cut through Paris to go all the way North to Saint Ouen. Dextra supplied more than 70,000 Fortec couplers used in the stations of Orsay and Pont Cardinet.

Expansion of Line 14 is part of the Grand Paris Express urban transportation plan. The fast subway line’s expansion will soon cut through Paris to go all the way North to Saint Ouen. Dextra supplied more than 70,000 Fortec couplers used in the stations of Orsay and Pont Cardinet.

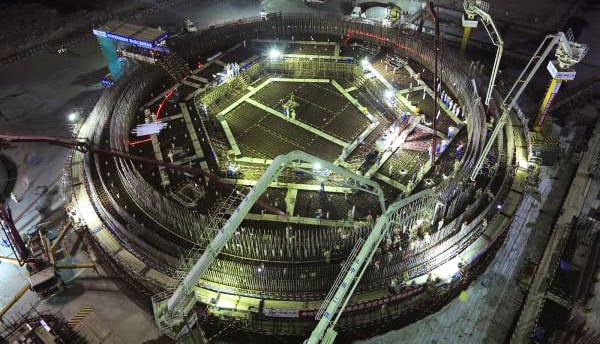

Qatar’s General Electricity & Water Corporation (KAHRAMAA) is currently building an ambitious new structure which aims to store the equivalent of 7 days of national consumption of fresh water at WHO (World Health Organization) standard’s quality.

5 brand new reservoirs of 3.5 million m3 each are currently being built, among the largest of their kind in the world.

For this ambitious project, Dextra Middle East already delivered more than 300,000 Bartec coupler to the fabricators and contractors involved on the different packages.

Project requirements regarding corrosion protection specify that the complete

Qatar’s General Electricity & Water Corporation (KAHRAMAA) is currently building an ambitious new structure which aims to store the equivalent of 7 days of national consumption of fresh water at WHO (World Health Organization) standard’s quality.

5 brand new reservoirs of 3.5 million m3 each are currently being built, among the largest of their kind in the world.

For this ambitious project, Dextra Middle East already delivered more than 300,000 Bartec coupler to the fabricators and contractors involved on the different packages.

Project requirements regarding corrosion protection specify that the complete

Dextra is releasing a full update of its rebar coupler design tools for Autocad (from version 2010) and Tekla (from version 19 ).

The new Autocad Palette tool will allow you to quickly insert couplers in your drawings, modify

Dextra is releasing a full update of its rebar coupler design tools for Autocad (from version 2010) and Tekla (from version 19 ).

The new Autocad Palette tool will allow you to quickly insert couplers in your drawings, modify  sizes even after insertion, track quantities and run bill of materials.

Tekla components allow drag-&-drop inside your workspace with automatic rebar size recognition to save time.

The whole Dextra range is supported (standard/position,

sizes even after insertion, track quantities and run bill of materials.

Tekla components allow drag-&-drop inside your workspace with automatic rebar size recognition to save time.

The whole Dextra range is supported (standard/position,

The London building market is one of the most dynamic in Europe. UK contractors increasingly take advantage of the benefits of

The London building market is one of the most dynamic in Europe. UK contractors increasingly take advantage of the benefits of

Soletanche Bachy commissioned Dextra with the delivery of tie rods for Quay H container terminal in Sète, France.

Ball cages for M160 tie rods have been installed into the

Soletanche Bachy commissioned Dextra with the delivery of tie rods for Quay H container terminal in Sète, France.

Ball cages for M160 tie rods have been installed into the

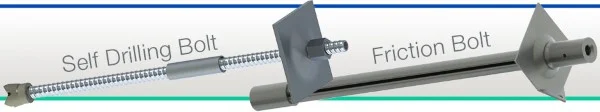

Dextra Friction Bolts allow a fast and clean rock bolting for all

Dextra Friction Bolts allow a fast and clean rock bolting for all

Tech companies are well known for their radical approach to the organization of work space. Facebook’s expansion of Menlo Park headquarter is no exception.

Designed by the famous architect Frank Gehry, the new building features the largest open-pla

Tech companies are well known for their radical approach to the organization of work space. Facebook’s expansion of Menlo Park headquarter is no exception.

Designed by the famous architect Frank Gehry, the new building features the largest open-pla n office in the world, innovative collaborative spaces and a gigantic 37,000 sqm rooftop garden.

For this project, Dextra supplied Bartec couplers as well as

n office in the world, innovative collaborative spaces and a gigantic 37,000 sqm rooftop garden.

For this project, Dextra supplied Bartec couplers as well as  By the way, Dextra is also on Facebook, feel free to

By the way, Dextra is also on Facebook, feel free to

Temporary ground anchors are used in numerous applications including slope stabilization and excavations. Contractors usually install steel ground anchors, and then remove them once they become obsolete: a double burden.

Temporary ground anchors are used in numerous applications including slope stabilization and excavations. Contractors usually install steel ground anchors, and then remove them once they become obsolete: a double burden.

Dextra supplies a complete range of Pre-Stressing and Post-Tensioning high performance bars. Dextra product range includes fully threaded bars (3 grades available) and smooth bars with threaded ends (also available in 3 grades) and are supplied with plates and nuts.

Dextra supplies a complete range of Pre-Stressing and Post-Tensioning high performance bars. Dextra product range includes fully threaded bars (3 grades available) and smooth bars with threaded ends (also available in 3 grades) and are supplied with plates and nuts.

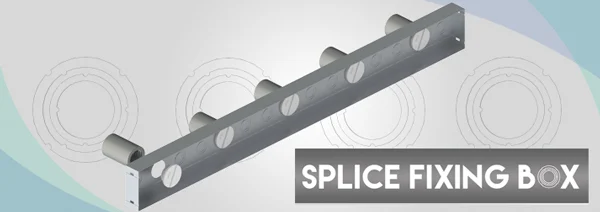

Dextra released a new accessory to support its coupler product range for both in situ casting and precast applications.

Dextra released a new accessory to support its coupler product range for both in situ casting and precast applications.

Tanger Med 2 is a port expansion project directed by Bouygues and Saipem near Tangier, Morocco. It features a new port area protected by 105 caissons, each of them including more than 6 tons of reinforced concrete. For this project Dextra supplied 180,000 Rolltec couplers supported by a couple of on-site Rolltec rebar preparation equipment. Couplers were used in various areas of the caisson, including vertical inside walls and horizontal slabs on the top of the structure.

Tanger Med 2 is a port expansion project directed by Bouygues and Saipem near Tangier, Morocco. It features a new port area protected by 105 caissons, each of them including more than 6 tons of reinforced concrete. For this project Dextra supplied 180,000 Rolltec couplers supported by a couple of on-site Rolltec rebar preparation equipment. Couplers were used in various areas of the caisson, including vertical inside walls and horizontal slabs on the top of the structure.

Also in Bangkok, HR and Quality department teamed up to organize the 3rd edition of Dextra Manufacturing annual “Quality & Safety Days”, a crucial part of a long-term strategy to boost Quality and Safety. This 2 day event is dedicated to the promotion of safety practices and quality awareness through numerous activities for factory operators and office staff.

Also in Bangkok, HR and Quality department teamed up to organize the 3rd edition of Dextra Manufacturing annual “Quality & Safety Days”, a crucial part of a long-term strategy to boost Quality and Safety. This 2 day event is dedicated to the promotion of safety practices and quality awareness through numerous activities for factory operators and office staff.

The Jamnagar Refinery of Reliance Industries Ltd. is the world’s largest refinery. The complex, located in the Indian state of Gujarat, spreads over more than 3000 ha, a city of its own! Its production capacity is already of 1.2 million barrels per day.

The Jamnagar Refinery of Reliance Industries Ltd. is the world’s largest refinery. The complex, located in the Indian state of Gujarat, spreads over more than 3000 ha, a city of its own! Its production capacity is already of 1.2 million barrels per day.

Dextra inaugurated a few weeks ago a new factory building in Bangkok, adjacent to its existing manufacturing facilities.

Dextra inaugurated a few weeks ago a new factory building in Bangkok, adjacent to its existing manufacturing facilities.

couplers are engineered to be used with standard non-shrinking grouting mortar, filled by gravity or injection.

couplers are engineered to be used with standard non-shrinking grouting mortar, filled by gravity or injection.

Dextra recently supplied to Abu Dhabi International Airport steel compression struts that will support the structure of the new Midfield Terminal Complex.

Dextra recently supplied to Abu Dhabi International Airport steel compression struts that will support the structure of the new Midfield Terminal Complex.

Dextra is proud to be part of the mega project that will soon link Hong Kong, Zhuhai and Macau. The 50 km long structure, which includes a main bridge of 29.6 km and a 6.9 km tunnel, is expected to be completed by 2016.

Dextra is proud to be part of the mega project that will soon link Hong Kong, Zhuhai and Macau. The 50 km long structure, which includes a main bridge of 29.6 km and a 6.9 km tunnel, is expected to be completed by 2016.

Rio de Janeiro is creating a new line for its subway, getting its city infrastructures ready for two major upcoming sport events, the 2014 FIFA World Cup and the 2016 Rio Olympics.

Rio de Janeiro is creating a new line for its subway, getting its city infrastructures ready for two major upcoming sport events, the 2014 FIFA World Cup and the 2016 Rio Olympics.