A Game-Changer for Rebar Fabrication

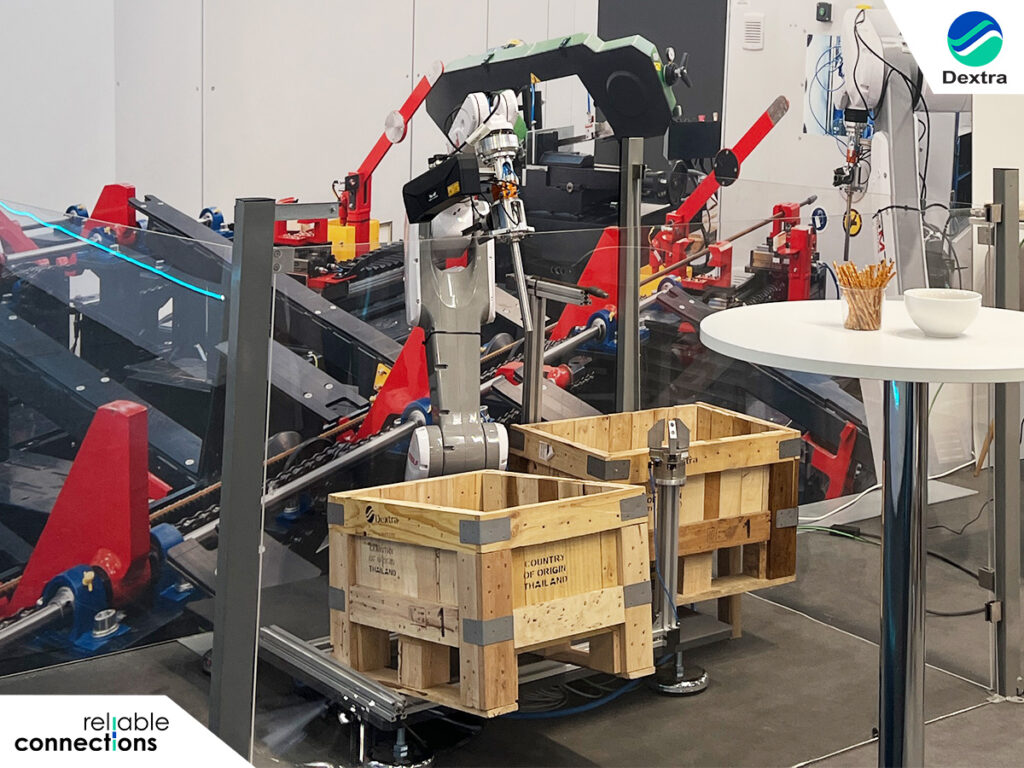

In the ever-evolving world of construction, efficiency and automation are becoming the defining factors for success. Dextra, in collaboration with GMT Robotics, introduces a groundbreaking innovation—the Griptec AutoRack. Designed to streamline rebar handling and fabrication, this automated rebar processing system eliminates manual bottlenecks, reduces labor costs, and ensures unmatched precision.

For rebar fabricators, the ability to run production 24/7 has long been a dream. With the Griptec AutoRack, that dream is now a reality.

What is the Griptec AutoRack?

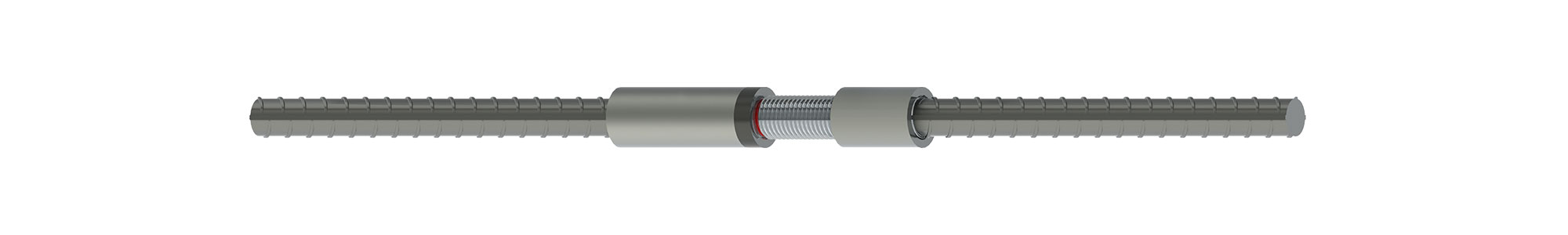

The Griptec AutoRack is an advanced automated rebar handling system designed specifically for the Dextra Griptec solution.

It facilitates the seamless movement of rebar through multiple stages of processing, ensuring continuous workflow with minimal human intervention. The system is engineered to optimize efficiency, increase productivity, and enhance quality in rebar fabrication plants.

Key functions of the Griptec AutoRack include:

- Automated rebar feeding – Moves rebar through different stages without manual handling.

- High-speed processing – Reduces wait times and increases throughput.

- Smart control system – Integrates seamlessly with existing production lines.

- Non-stop operation – Enables fabricators to operate their production line 24/7.

Why Automation in Rebar Handling?

Traditional rebar processing relies heavily on manual labor, leading to inefficiencies, inconsistencies, and increased operational costs. The introduction of automation with the Griptec AutoRack directly addresses these challenges by offering:

How It Works

The Griptec AutoRack is built to work seamlessly within a rebar processing facility. Here’s how it enhances operations:

- Automated Feeding: Rebar is automatically loaded into the system, eliminating the need for manual handling at the start of the process.

- Precision Movement: The system ensures that each bar is positioned and transported with high accuracy, reducing material waste.

- Integration with Cutting and Threading Machines: The AutoRack coordinates perfectly with existing rebar processing equipment, streamlining operations.

- Smart Monitoring: Advanced control systems track each stage of production, ensuring efficiency and quality control in real-time.

- Effortless Output: The processed rebar is automatically sorted and prepared for the next stage, ready for transportation or on-site use.

Where to See the Griptec AutoRack in Action?

The Griptec AutoRack will be on full display at bauma 2025, where attendees can witness its capabilities firsthand. This is an exclusive opportunity to see how automation is transforming the rebar industry and how Dextra and GMT Robotics are leading the way.

Don’t miss out! Visit us at bauma 2025 and see the Griptec AutoRack in action.

The Griptec AutoRack represents a major leap forward in rebar fabrication efficiency, automation, and cost-effectiveness. By enabling 24/7 automated production, reducing labor dependency, and ensuring consistent quality, it is set to redefine how the construction industry handles rebar processing.

If you’re looking for a way to maximize productivity, cut costs, and stay ahead in the industry, the Griptec AutoRack is the solution you’ve been waiting for.