दोहा मेट्रो मशीरेब स्टेशन

मशीरेब स्टेशन दोहा मेट्रो का प्रमुख इंटरचेंज स्टेशन है। डाउनटाउन दोहा में स्थित, यह सभी तीन लाइनों (लाल, हरा और सोना) को जोड़ता है और 2022 फीफा विश्व कप 2022 स्टेडियमों के लिए एक प्रवेश द्वार प्रदान करेगा।

मशीरेब स्टेशन आकार के हिसाब से दुनिया के सबसे बड़े सबवे स्टेशनों में से एक बन जाएगा।

कोमल-आँखें for TBMs

For this major project, Dextra engineered and supplied between 2013 and 2015 8 large ASTEC GFRP Soft-Eyes, of a diameter of 8 meters each. Soft Eyes are cages of GFRP rebar, positioned into the D-Walls in-between steel segments. GFRP Soft-Eyes allow Tunnel Boring Machines (TBMs) to go through in a minimum time as the bars can be easily crushed by the tunnel machine.

टाई-बैक एंकर

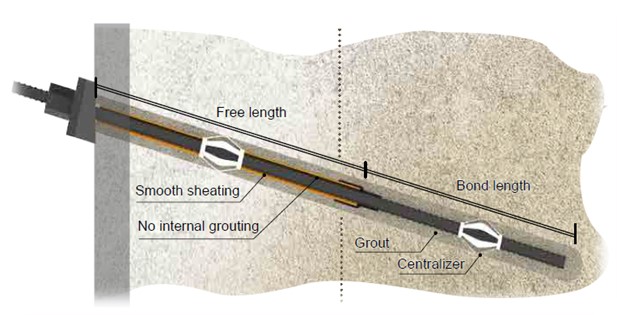

To anchor the massive d-walls and prevent any soil displacement during excavation works, Dextra also supplied its ASTEC Active Anchors (AAA). Those innovative post-tensioned GFRP-based anchors, have the benefits of being cut by the Tunnel Boring Machines or standard excavation equipment. Because it can be easily cut, it doesn’t need to be removed from the ground, even when used for temporary applications.

मशीरेब स्टेशनों के मामले में, डी-वॉल को एंकर करने के लिए सॉफ्ट-आई के केंद्र में मल्टी-टेंडन्स एंकर (इस प्रोजेक्ट पर प्रति एंकर 10) भी स्थापित किए गए हैं। सुरंग तोड़ने के दौरान उन एंकरों को भी काट दिया गया था (नीचे दिए गए वीडियो में दिखाई दे रहा है)। स्टेशन पर कुल 150 लंगर लगाए गए।