Cuttable rod and grouting pipe in one!

GEOTEC FRP Hollow Rock Bolt is a rock-bolting system based on fully threaded hollow GFRP bars.

It is especially designed for the following applications:

- Face-bolting and temporary applications : Cut-ability of FRP makes it the ideal solutions for face bolting or any other tunneling/mining application where further excavation is required.

- Cohesive soil and hard rock conditions. GEOTEC are inserted into pre-drilled hole. For non-cohesive soil environment, refer instead to FRP Self-Drilling Bolts.

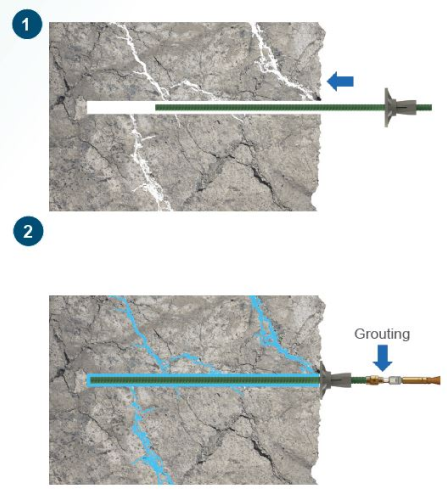

- Installation with grout. The hollow GFRP anchor rod also acts as a grouting pipe to ease installation.

Product features

- 2 in 1 system = act as both anchor rod and grouting pipe.

- Standard range available in 4 diameters ranging from 25mm to 38mm.

- Can be delivered with GFRP (cut-able) or steel plate and nuts.

- Additional high performance ASTEC model available in 32mm with body tensile loads ≥480 kN. Delivered with Domed Plate & Nut, making system suitable for installation on uneven surfaces.

- Designed as per BS EN 1997-1; BS EN 1537 and BS 7861-1.

Hollow rod

Acts as a grouting pipe to simplify

installation process.

Cuttable systems

By standard earth moving and

mining equipment, including the

plate/nuts accessories!

Light weight

Easy handling, transportation and

installation inside the tunnel.

Related Projects

Related solutions

Specific tunneling application of GFRP rebar cage allowing a TBM to break through a reinforcement cage in a minimum time.

Soil Stabilization: Fully cut-able FRP soil nail system used for the stabilization of slope.

Soil Retention: Post-tensioned steel ground anchor system used in excavation works.

Expertise

At every moment of your customer journey, Dextra teams dedicate themselves to the production of smart construction solutions that allow our customers to reach higher productivity and safety levels on their construction sites.

Dextra holds physical stocks on several continents, complemented in each country by the local inventories of our distributors. With this extended network, Dextra makes sure our products are always at reach no matter where our partners are.

For solutions that require to be customized, Dextra can also go beyond our standard delivery times and offer accelerated delivery schemes. Consult us for more information.

From 3 major industrial sites located in Bangkok (Thailand), Guangzhou (China), and Pune (India), Dextra completely owns its manufacturing facilities and processes. This allows us to have complete control over the timing of our operations and the quality of the solutions produced.

An independently accredited material testing laboratory, accredited to ISO-IEC17025, is located at Dextra’s main Bangkok factory, allowing the testing of material and products.

Dextra aims to supply products that exceed the most demanding international technical approvals and it is our goal to create maximum customer satisfaction by complying with our clients’ needs and specified requirements.