Centrale électrique à cycle combiné solaire intégrée de Green Duba

Duba ISCC Green Power Plant 1 is a large power infrastructure project located in the northwest of Saudi Arabia, along the Red Sea. The ISCC (Integrated Solar Combined Cycle) technology adds 50 MW of solar power to the gas and steam turbines, generating a total of 500 MW of electricity.

For this project, Dextra supplied Double Corrosion Protection Ground Anchors, used as a permanent anchoring solution for the excavation work preparing the pumping chamber. A total of 264 anchors (Grade 1080/1230, Ø32 & 40 mm) were supplied and installed across four layers.

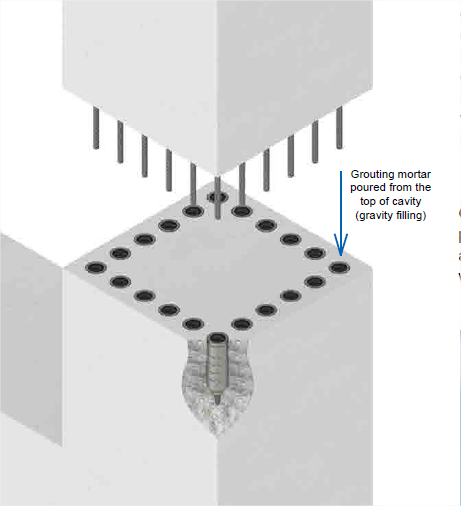

Le Double Corrosion Protection anchors supplied for this project were pre-grouted at the Dextra factory, applying the first layer of grout between the steel bar and HDPE sleeve. The pre-grouted segments were reconnected on-site using couplers. Pre-grouted anchors not only save time and reduce costs during on-site operations, but they also enhance overall anchor quality by ensuring that the first grout layer is applied in a factory-controlled environment.

L'installation sur site a été réalisée par l'entrepreneur en fondations BAUER, qui a réalisé les opérations de forage, de levage, d'installation, d'injection et de post-tension. Dextra a offert des conseils dès les premières étapes de l'installation en envoyant une équipe de spécialistes géotechniques sur place.

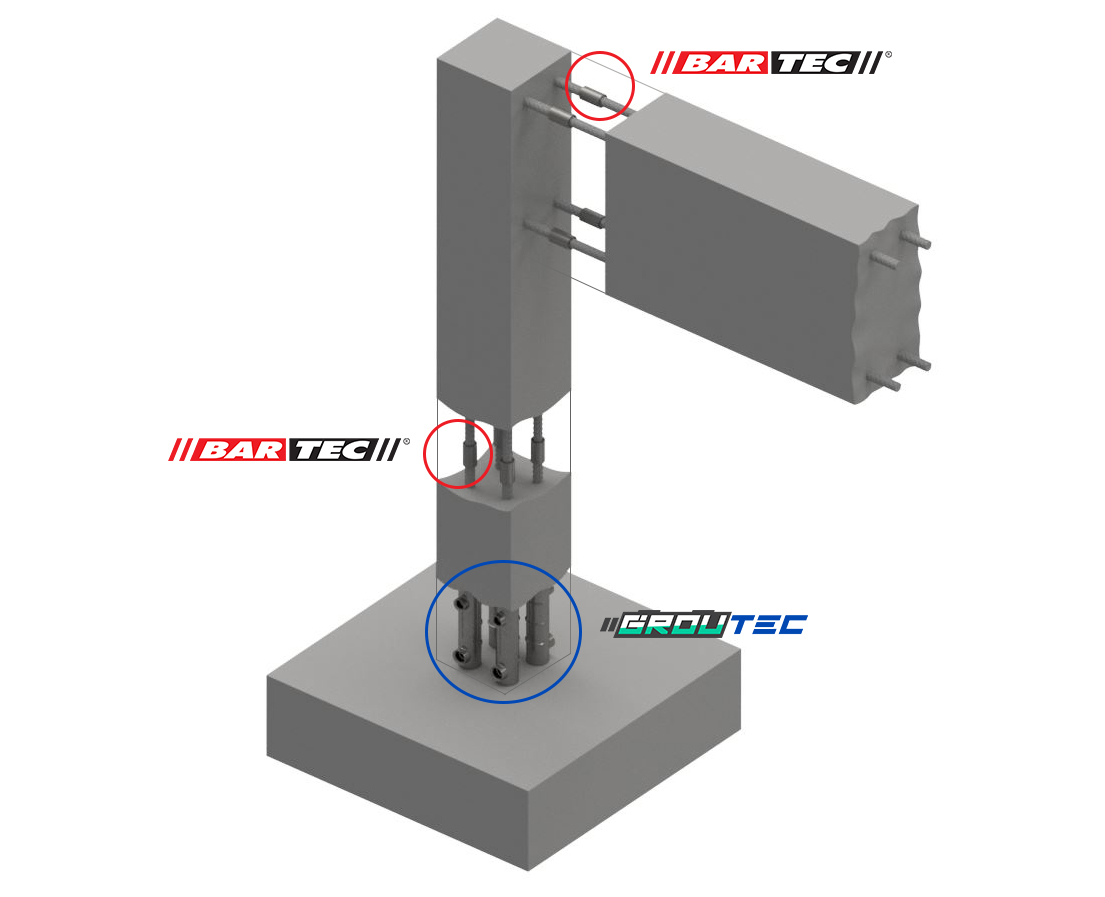

La séquence générale d'installation est la suivante (illustrée dans les images ci-dessous) :

- Après déballage des racks d'expédition, épissage des segments avec des coupleurs, recouverts de gaines thermorétractables.

- Transport de l'ancre assemblée de l'assemblage au chantier jusqu'à la zone de levage (13 kg par mètre linéaire).

- Câble de câblage en tête d'ancre pour contrôler la descente. Tuyau d'injection également préinstallé le long de l'ancrage.

- Insertion de l'ancre de 30 mètres dans le trou foré avec le tuyau d'injection.

- Après le jointoiement et la contrainte, un capuchon rempli de graisse est installé sur la tête d'ancrage, maintient l'ancre entièrement isolée de l'environnement extérieur corrosif.

Pour plus d'informations sur nos solutions d'excavation et de sol au Moyen-Orient, veuillez contacter notre Bureau de Dubaï.