EPR de Flamanville

Flamanville est le premier réacteur construit d'après la conception EPR (European Pressurized Reactor) de nouvelle génération, d'après une conception chinoise 100%. Il aura une capacité de 1,3 GWe lors de sa mise en service en 2019.

Dextra est présent sur place depuis le début des travaux en 2008 et jusqu'en 2015.

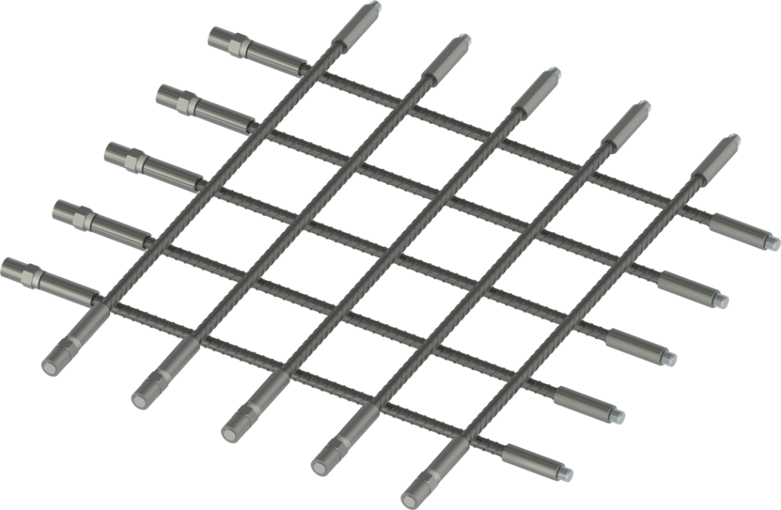

For this challenging project, Dextra has been supplying its Griptec rebar Solution de raboutage through its local fabricator partners. The rebar preparation was supported by an additional machine placed on site.

Griptec is the preferred rebar Solution de raboutage of the nuclear industry thanks to its unique performance level and an automatic testing process which systematically tests all the connections produced as part of its standard cycle: a guarantee that 100% of the connections perform above project requirement.

More than 800,000 Griptec connections have been used on the project, including 400,000 position assemblies, allowing the connection of large diameter rebar without rotating them. The Griptec connections have been installed on the reactor building and Coque avion, as well as Bâtiments annexes.

In particular, Griptec has been used for the connections of large prefabricated panels.

Manchon femelle et Pion pontage” width=”303″ height=”198″ />

Manchon femelle et Pion pontage” width=”303″ height=”198″ />

Four-sided panels with Griptec Manchon femelle et Pion pontage

Thanks to its Assemblage pontage, Panneau sandwich (?) could be reconnected on four-sided panels while coping for possible misalignment that occurs when lifting the cage.