Forrestfield Airport Link

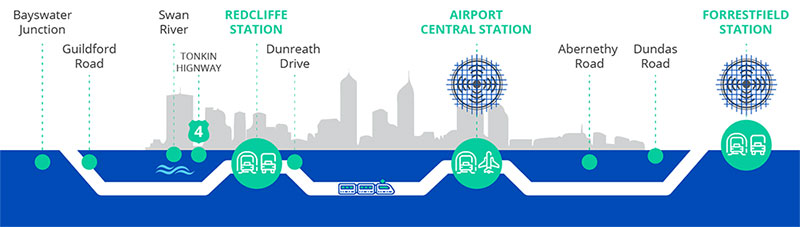

The Forrestfield Airport Link is a rail infrastructure project lolcated in Perth, Western Australia. The 8.5km line will connect the existing Midland Line to Perth International Airport and further to the eastern suburbs. The project features two twin-tunnels bored with Tunnel Boring Machines (TBMs) which move up to 26 meter underneath the bed of Swan river, highways and Perth Airport, adding three new stations to the city’s transportation network: Belmont, Airport Central and Forrestfield.

For the tunnel boring packages, Dextra supplied a total of 10 GFRP Soft-Eyes between 2016 and 2017 (two for Airport Central Station, two in Abernethy, four in Belmont and two in Bayswater) to the contractor JV of Salini Impregilo and NRW Salini Impregilo. Soft-Eyes are rebar cages made mostly of Glass-Fiber Reinforced Polymer (GRFP) bars and some steel rebar. Soft-Eyes can be cut by the TBMs and allow faster equipment breakthrough, saving precious time while avoiding to damage the TBM heads.

Dextra also supplied a total of 65,000 Griptec connections for the station works. Griptec is distributed in Western Australia by Dextra’s partner InfraBuild Construction Services. They offer the complete service to the contractor: Cutting the rebar, preparing the bar ends with Griptec sleeves and bending them for final installation on site. This allows the contractor to achieve faster cycle times in rebar connection on site .

Sonitec, Dextra’s steel tubes for Crosshole Sonic Logging tests (to check concrete integrity in bored piles) were also supplied.

The Forrestfield-Airport Link will operate in 2022.

For more information about our solutions in Australia, please consult our Bangkok office