La revitalización de un monumento histórico del Reino Unido

La central eléctrica de Battersea, totalmente desmantelada hace casi 40 años, está siendo reconstruida en uno de los proyectos de construcción más grandes de la historia del Reino Unido.

La central eléctrica de Battersea, totalmente desmantelada hace casi 40 años, está siendo reconstruida en uno de los proyectos de construcción más grandes de la historia del Reino Unido.

Se estima que el proyecto de reurbanización en siete fases tendrá un valor de £8.000 millones ($13.000 millones).

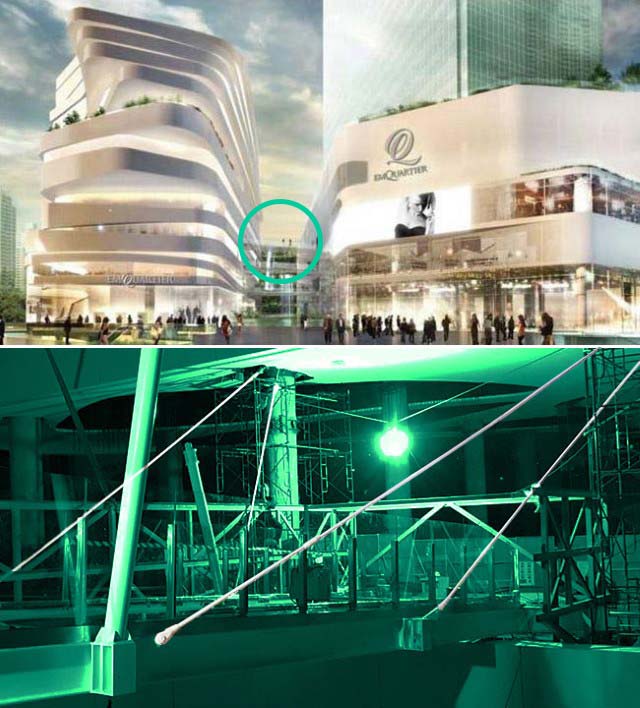

La tercera fase consiste en la creación del llamado 'Bulevar Eléctrico', que en Incluye una conexión con la estación Northern Line Extension, más de 1.300 unidades residenciales, un hotel de 160 habitaciones, espacios comerciales, restaurantes e instalaciones de ocio.

Incluye una conexión con la estación Northern Line Extension, más de 1.300 unidades residenciales, un hotel de 160 habitaciones, espacios comerciales, restaurantes e instalaciones de ocio.

La amplia gama de soluciones de refuerzo de hormigón proporcionada por Dextra resultó ideal para este proyecto emblemático.

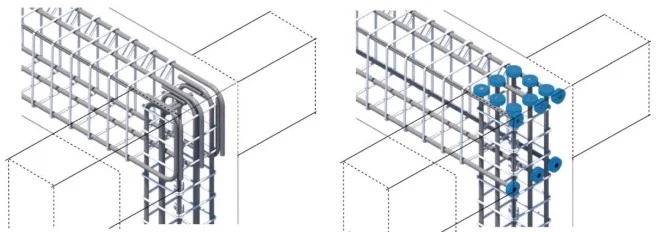

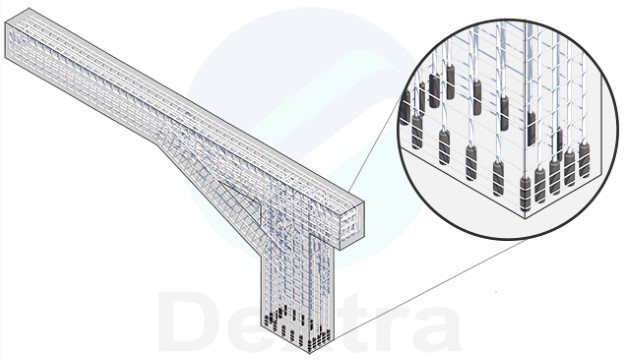

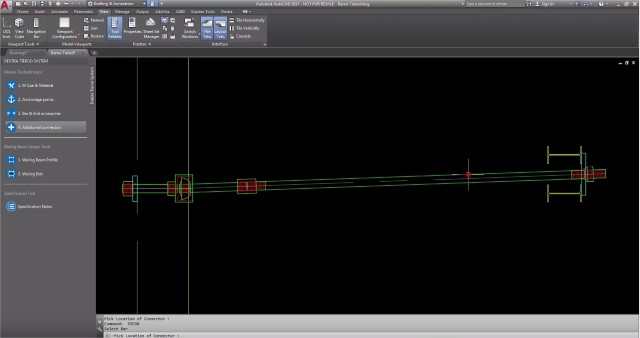

Diferentes gamas de acopladores Se han suministrado para aplicaciones de hormigón prefabricado, de hormigón colado in situ y de reparación, específicamente:

Se han suministrado para aplicaciones de hormigón prefabricado, de hormigón colado in situ y de reparación, específicamente:

- 100.000 acopladores Griptec y Rolltec fundidos in situ

- 30.000 acopladores prefabricados de Groutec

- 3.000 acopladores atornillados Unitec

ICCX Central Europe 2020: ¡reserva la fecha!

Visite a Dextra en la ICCX Central Europe 2020 del 12 al 13 de febrero.

En el Double Tree Hotel by Hilton Hotel & Conference, Varsovia, Polonia.

Descubra nuestras reconocidas soluciones de conexión de varillas de refuerzo y la última tecnología de conexión de elementos prefabricados en stand #55¡De 9 a 18 horas!

Nuevo Sonitec V2

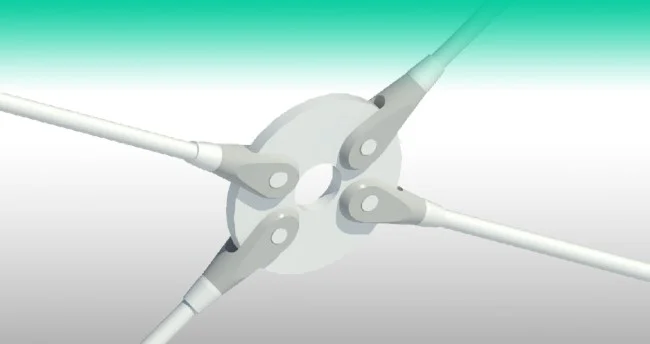

Sonitec es una solución de tubos diseñada para facilitar las pruebas de integridad de las cimentaciones utilizando el método de prueba Cross Sonic Logging (CSL).

El lanzamiento de esta nueva versión representa un hito importante para Dextra, aportando algunas características únicas al mercado:

- Técnica de expansión en frío con una tensión residual limitada alrededor del orificio

- Forma robusta sin deformaciones térmicas

- Los sellos de caucho están estandarizados y se pueden subcontratar y reemplazar fácilmente.

Más sobre nuestros últimos proyectos

EE. UU. – Puente sobre el río Smith

Los acopladores de barras de refuerzo y las barras con cabeza de Bartec soportaron el refuerzo de la estructura del puente.

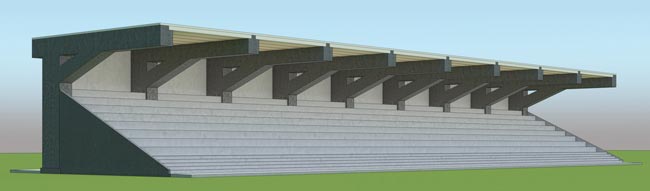

Qatar – Estadio Ras Abu Aboud

Se instalaron barras de tensión en este innovador estadio modular construido específicamente para el torneo de la Copa Mundial de la FIFA 2022.

Reino Unido – Ampliación del puerto de Aberdeen

La expansión de uno de los puertos más antiguos del Reino Unido se vio facilitada por el uso de Sonitec para la prueba CSL.

Entrevista con SKM Steel Holdings

” De apoyo, sistemático y rápido.:Así es como describiríamos a Dextra”.

Conozca SKM Steel Holdings, una empresa conjunta entre Steel King Company Ltd. de Myanmar y Mitsui & Co. de Japón, especializada en la fabricación de acero cortado y doblado.

Descubra por qué han elegido a Dextra como socio desde el primer día de operaciones.

Nuestra Gente

Estoy a 7000 kilómetros de casa y aquí en Dubái, mi segundo hogar es Dextra Middle East. En el trabajo, podemos expresarnos como si fuera una empresa familiar y no una multinacional.

Estoy a 7000 kilómetros de casa y aquí en Dubái, mi segundo hogar es Dextra Middle East. En el trabajo, podemos expresarnos como si fuera una empresa familiar y no una multinacional.

– Sra. Mary Grace, Coordinadora de Ventas,

8 años en Dextra Oriente Medio

En nombre de todos los empleados de Dextra, nos gustaría desearle a usted y a sus seres queridos un muy feliz y próspero año nuevo.

Esperamos poder ofrecerle nuestro mejor servicio durante el nuevo año.

¡Construyamos juntos en 2020!

El proyecto del Metro de El Cairo se lanzó por primera vez hace 30 años y desde entonces revolucionó el sistema de transporte de la ciudad.

El proyecto del Metro de El Cairo se lanzó por primera vez hace 30 años y desde entonces revolucionó el sistema de transporte de la ciudad. y

y

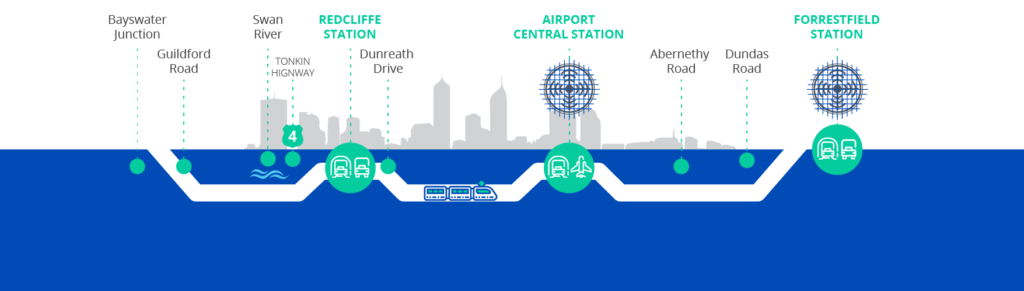

La línea Thomson-East Coast es un proyecto de MRT muy ambicioso en Singapur, que se intercambiará con todas las líneas existentes.

La línea Thomson-East Coast es un proyecto de MRT muy ambicioso en Singapur, que se intercambiará con todas las líneas existentes. los proyectos de tránsito subterráneo más grandes del mundo, brindando una solución rentable y eficiente en términos de tiempo.

los proyectos de tránsito subterráneo más grandes del mundo, brindando una solución rentable y eficiente en términos de tiempo.

El agua toma el escenario durante estos días festivos, desde las alegres guerras de agua en las calles de Bangkok, hasta el “Rod Nam Dam Hua”, un ritual donde se vierte agua sobre las manos de ancianos venerados.

El agua toma el escenario durante estos días festivos, desde las alegres guerras de agua en las calles de Bangkok, hasta el “Rod Nam Dam Hua”, un ritual donde se vierte agua sobre las manos de ancianos venerados. “Estoy orgulloso de apoyar a nuestros clientes: podemos ofrecerles soluciones más económicas para que puedan trabajar con mayor eficacia”.

“Estoy orgulloso de apoyar a nuestros clientes: podemos ofrecerles soluciones más económicas para que puedan trabajar con mayor eficacia”.

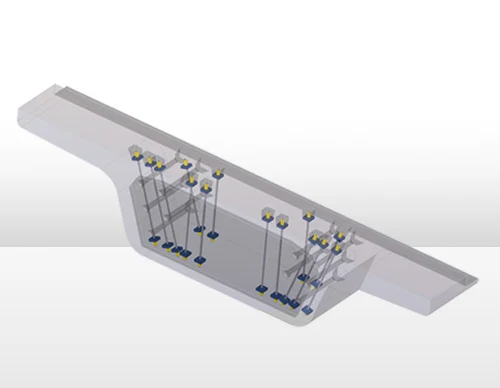

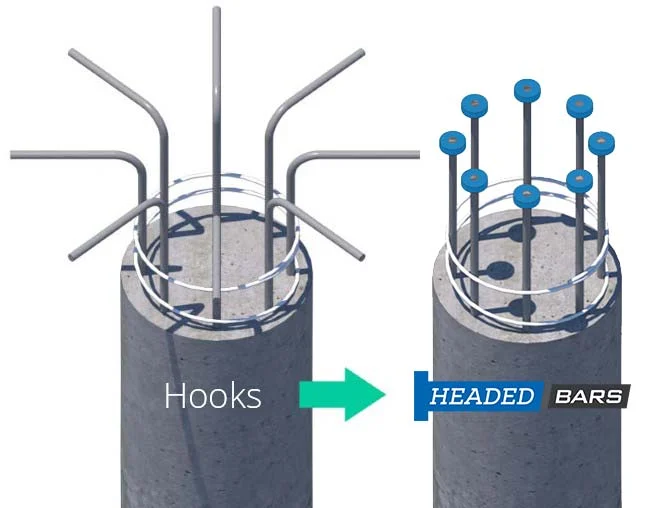

La Autopista de Enlace Cebú-Córdova (CCLEX) es uno de los proyectos de infraestructura más grandes que se están llevando a cabo en Filipinas. El proyecto incluye una calzada elevada, un puente atirantado de peaje de 8,5 km de longitud que cruzará la zona navegable del Estrecho de Cebú, dos viaductos y cuatro puentes de baja altura, además de calzadas y pasos peatonales.

La Autopista de Enlace Cebú-Córdova (CCLEX) es uno de los proyectos de infraestructura más grandes que se están llevando a cabo en Filipinas. El proyecto incluye una calzada elevada, un puente atirantado de peaje de 8,5 km de longitud que cruzará la zona navegable del Estrecho de Cebú, dos viaductos y cuatro puentes de baja altura, además de calzadas y pasos peatonales. En las jaulas de pilotes de cimentación se han utilizado empalmes estándar, de puente y de transición en diámetros de 40 y 50 mm con barras de grado 75.

En las jaulas de pilotes de cimentación se han utilizado empalmes estándar, de puente y de transición en diámetros de 40 y 50 mm con barras de grado 75.

“Dado que estamos realizando muchos proyectos en producción, mis funciones son controlar la programación del proyecto y cómo mantenerlo según lo previsto (…)

“Dado que estamos realizando muchos proyectos en producción, mis funciones son controlar la programación del proyecto y cómo mantenerlo según lo previsto (…)

También llamado el Tercer Puente sobre el Canal de Panamá, el Puente del Atlántico, de 2,8 kilómetros, es uno de los puentes atirantados de hormigón más largos del mundo.

También llamado el Tercer Puente sobre el Canal de Panamá, el Puente del Atlántico, de 2,8 kilómetros, es uno de los puentes atirantados de hormigón más largos del mundo. de grandes buques portacontenedores, Post-Panamax, con su altura libre de 75 metros sobre el nivel del mar.

de grandes buques portacontenedores, Post-Panamax, con su altura libre de 75 metros sobre el nivel del mar. Grandes Proyectos. Los acopladores Bartec de alto rendimiento sustituyen el solape en varillas de refuerzo de hasta #14 (equivalente a 43 mm) en acero de grado 80.

Grandes Proyectos. Los acopladores Bartec de alto rendimiento sustituyen el solape en varillas de refuerzo de hasta #14 (equivalente a 43 mm) en acero de grado 80.

“Siempre he estado buscando más responsabilidades (…) Dextra me da esta oportunidad y también me empodera.

“Siempre he estado buscando más responsabilidades (…) Dextra me da esta oportunidad y también me empodera.

Mi objetivo es brindar la mejor solución a nuestros clientes en el menor tiempo posible. Me enorgullece formar parte de Dextra y me esfuerzo por garantizar la satisfacción de nuestros clientes.

Mi objetivo es brindar la mejor solución a nuestros clientes en el menor tiempo posible. Me enorgullece formar parte de Dextra y me esfuerzo por garantizar la satisfacción de nuestros clientes.

Con la aspiración de convertirse en un centro regional, el aeropuerto de Kuwait aumenta su capacidad. El proyecto de ampliación del Aeropuerto de Kuwait busca satisfacer el rápido y significativo crecimiento económico del país y el constante aumento del flujo de pasajeros y carga. La nueva Terminal II está diseñada no solo para brindar la máxima comodidad a los pasajeros, sino también para reflejar la rica cultura y civilización de Kuwait. Una vez finalizado, el edificio tendrá la forma de un triángulo simétrico. La capacidad de pasajeros del aeropuerto aumentará a 25 millones en la primera fase de la ampliación, lo que representaría más del doble de lo que gestiona actualmente. El Ministerio de Obras Públicas de Kuwait ha elaborado especificaciones muy estrictas para este proyecto emblemático, que requiere las certificaciones CARES del Reino Unido y ASME de EE. UU.

Con la aspiración de convertirse en un centro regional, el aeropuerto de Kuwait aumenta su capacidad. El proyecto de ampliación del Aeropuerto de Kuwait busca satisfacer el rápido y significativo crecimiento económico del país y el constante aumento del flujo de pasajeros y carga. La nueva Terminal II está diseñada no solo para brindar la máxima comodidad a los pasajeros, sino también para reflejar la rica cultura y civilización de Kuwait. Una vez finalizado, el edificio tendrá la forma de un triángulo simétrico. La capacidad de pasajeros del aeropuerto aumentará a 25 millones en la primera fase de la ampliación, lo que representaría más del doble de lo que gestiona actualmente. El Ministerio de Obras Públicas de Kuwait ha elaborado especificaciones muy estrictas para este proyecto emblemático, que requiere las certificaciones CARES del Reino Unido y ASME de EE. UU. Certificaciones del fabricante. Por lo tanto, los acopladores Rolltec® fueron la elección natural para el contratista Limak Insaat, ya que cumplen con todos los requisitos del cliente en términos de rendimiento y calidad, y el cliente contaba con una sólida presencia local y el apoyo de Dextra. Estándar Los acopladores Rolltec® se utilizan ampliamente para las conexiones de balsas, paredes y columnas de toda la terminal.Además, se entregaron acopladores soldables para la conexión de los noventa

Certificaciones del fabricante. Por lo tanto, los acopladores Rolltec® fueron la elección natural para el contratista Limak Insaat, ya que cumplen con todos los requisitos del cliente en términos de rendimiento y calidad, y el cliente contaba con una sólida presencia local y el apoyo de Dextra. Estándar Los acopladores Rolltec® se utilizan ampliamente para las conexiones de balsas, paredes y columnas de toda la terminal.Además, se entregaron acopladores soldables para la conexión de los noventa

El nuevo Aeropuerto Internacional de la Ciudad de México fue diseñado por Sir Norman Foster e inaugurado en 2014. Se ubica al este de la capital mexicana y busca dotar a la ciudad de un nuevo centro de transporte aéreo de vanguardia. El proyecto consta de una terminal en forma de X con una capacidad anual prevista de 68 millones de pasajeros, tres pistas y la torre de control.

El nuevo Aeropuerto Internacional de la Ciudad de México fue diseñado por Sir Norman Foster e inaugurado en 2014. Se ubica al este de la capital mexicana y busca dotar a la ciudad de un nuevo centro de transporte aéreo de vanguardia. El proyecto consta de una terminal en forma de X con una capacidad anual prevista de 68 millones de pasajeros, tres pistas y la torre de control.

En febrero, Dextra Middle East celebró 15 años de operaciones innovadoras en Dubái. Como nuestra primera entidad en la región del Golfo, DME es líder en soluciones técnicas para el sector de la construcción. Entre nuestros proyectos anteriores se incluyen el Aeropuerto Internacional de Dubái, la ampliación de Mecca Mataf y los megaembalses en Catar. Actualmente, trabajamos en la Torre de Yeda, el Aeropuerto Internacional de Kuwait y muchos otros proyectos destacados.

En febrero, Dextra Middle East celebró 15 años de operaciones innovadoras en Dubái. Como nuestra primera entidad en la región del Golfo, DME es líder en soluciones técnicas para el sector de la construcción. Entre nuestros proyectos anteriores se incluyen el Aeropuerto Internacional de Dubái, la ampliación de Mecca Mataf y los megaembalses en Catar. Actualmente, trabajamos en la Torre de Yeda, el Aeropuerto Internacional de Kuwait y muchos otros proyectos destacados.

El Louvre Abu Dabi es un nuevo e innovador museo de arte y civilización ubicado al norte de la ciudad de Abu Dabi, capital de los Emiratos Árabes Unidos. Es el museo más grande de la península arábiga, con una superficie total de 24.000 metros cuadrados. El Museo Louvre Abu Dabi abrió sus puertas el 11 de noviembre de 2017.

El Louvre Abu Dabi es un nuevo e innovador museo de arte y civilización ubicado al norte de la ciudad de Abu Dabi, capital de los Emiratos Árabes Unidos. Es el museo más grande de la península arábiga, con una superficie total de 24.000 metros cuadrados. El Museo Louvre Abu Dabi abrió sus puertas el 11 de noviembre de 2017. Aberturas en la estructura de refuerzo para el paso de personal y equipo. Se suministraron un total de 110.000 conexiones para este proyecto.

Aberturas en la estructura de refuerzo para el paso de personal y equipo. Se suministraron un total de 110.000 conexiones para este proyecto.

Forest City es un enorme desarrollo urbano de uso mixto ubicado cerca de Johor Bahru, en el sur de Malasia. Está construido sobre terrenos recuperados del mar a orillas del estrecho de Johor.

Forest City es un enorme desarrollo urbano de uso mixto ubicado cerca de Johor Bahru, en el sur de Malasia. Está construido sobre terrenos recuperados del mar a orillas del estrecho de Johor.

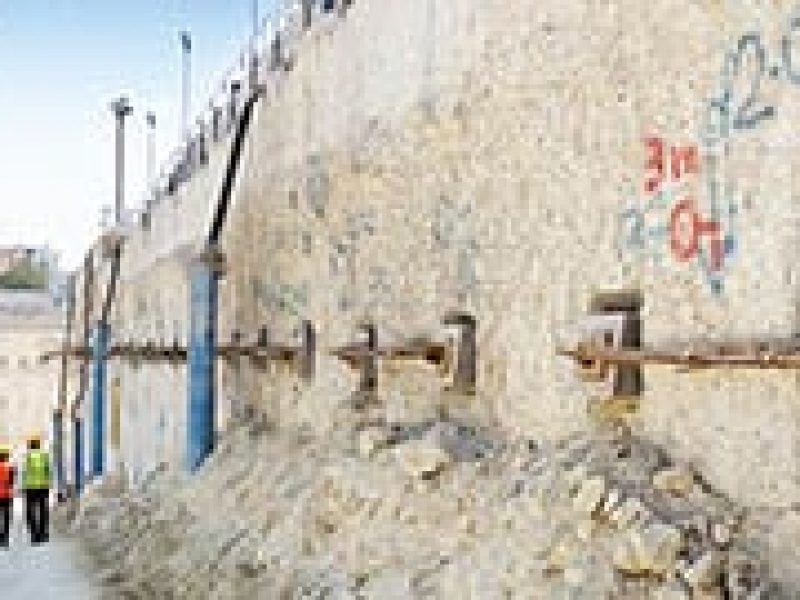

La refinería y terminal de Jizan es el último megaproyecto petrolero de Saudi Aramco y parte del Área Económica de Jizan.

La refinería y terminal de Jizan es el último megaproyecto petrolero de Saudi Aramco y parte del Área Económica de Jizan. En total, Dextra suministró 412 juegos de tirantes de tamaño M98, de acero de calidad 500. Los tirantes se conectaron a ambas paredes mediante las exclusivas soluciones de tuercas cautivas de Dextra.

En total, Dextra suministró 412 juegos de tirantes de tamaño M98, de acero de calidad 500. Los tirantes se conectaron a ambas paredes mediante las exclusivas soluciones de tuercas cautivas de Dextra.