Uniqlo & Hive Warehouse, Indonesia

Indonesia’s building construction sector has driven the demand for rapid and efficient construction methods to accommodate its growing population. Precast construction has emerged as a key solution to these challenges, helping to reduce on-site labor, accelerate project timelines, and ensure consistent quality.

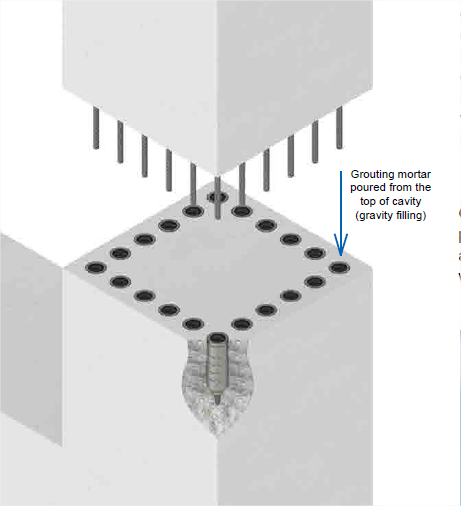

A seamless connection between structural elements is essential for the success of precast construction. Dextra supplied Groutec precast couplers for projects worldwide, including in Indonesia. Groutec couplers (20mm) were used in the Uniqlo & Hive Indonesia warehouse building project for joining precast columns, enabling rapid and reliable assembly while ensuring structural integrity.

The use of these couplers has minimized on-site labor requirements and expedited project milestones, leading to cost savings and timely project completion. This allows the building to become operational sooner. Additionally, the high-strength steel composition of the couplers, along with stringent quality control measures, ensures robust connections capable of withstanding dynamic structural loads.