Puerto Tánger Med 2

Tanger Med 2 es la ampliación de Tanger Med, un puerto marítimo de aguas profundas multipropósito situado a pocos kilómetros al este de Tánger, Marruecos, frente a Gibraltar.

La ampliación del puerto tiene como objetivo aumentar la capacidad anual del puerto más grande de África en 5,2 millones de contenedores.

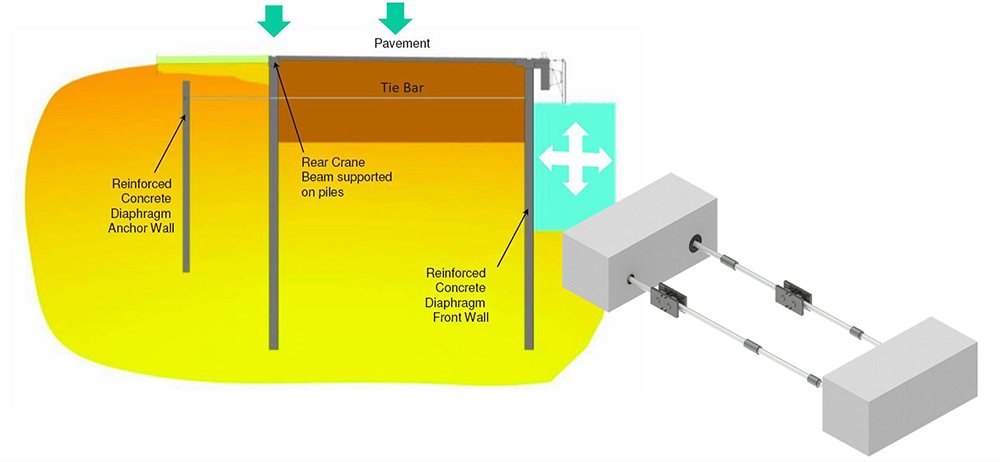

Para este gran proyecto de infraestructura, Dextra apoyó al contratista Bouygues con una solución de unión de barras de refuerzo para el refuerzo de los cajones.

Dextra suministró su Rolltec Solución certificada por AFCAB, requisito indispensable para este proyecto. Se instalaron dos máquinas Rolltec para apoyar las actividades de roscado, completando un total de 360.000 roscas (180.000 acopladores Rolltec).

Los acopladores se utilizaron para reforzar los cajones, cuya altura oscilaba entre 20 y 24 metros. Los acopladores proporcionaron:

- Aberturas temporales para solucionar problemas de congestión en el refuerzo dentro del cajón, creando pasos seguros para hombres y equipos durante la fase de instalación.

- Conexiones horizontales de muro a losa (desde el interior del perímetro del cajón hasta la losa). Para esta aplicación, se dejaron los acopladores pendientes, lo que permitió la elevación del encofrado deslizante.