Deep Tunnel Sewerage System (DTSS) – Phase 2

The Deep Tunnel Sewerage System (DTSS) is a used water infrastructure project being developed by the Public Utilities Board (PUB) of Singapore to meet the country’s long-term clean water needs.

DTSS deploys deep tunnels to convey used water to 3 centralised water reclamation plants (WRP) located in the coastal areas.

The used water is then treated and further purified into clean water to be supplied under the brand name NEWater, with excess treated effluent discharged to the sea through outfall pipes.

The project involves the construction of two large tunnels, 6.5m in diameter and with a total length of 80km, located about 50m below the surface, to carry sewage to 3 centralised WRPs.

The project is developed in two phases. The first phase was completed in 2008 and comprises a 48km-long underground tunnel system to channel the flow of water from existing gravity sewers to the Changi WRP in the east and Kranji WRP in the north.

The second phase will extend the tunnel system to the west through a 30km-long south tunnel, 60km of link sewers, the Tuas WRP and a 12-km deep-sea outfall.

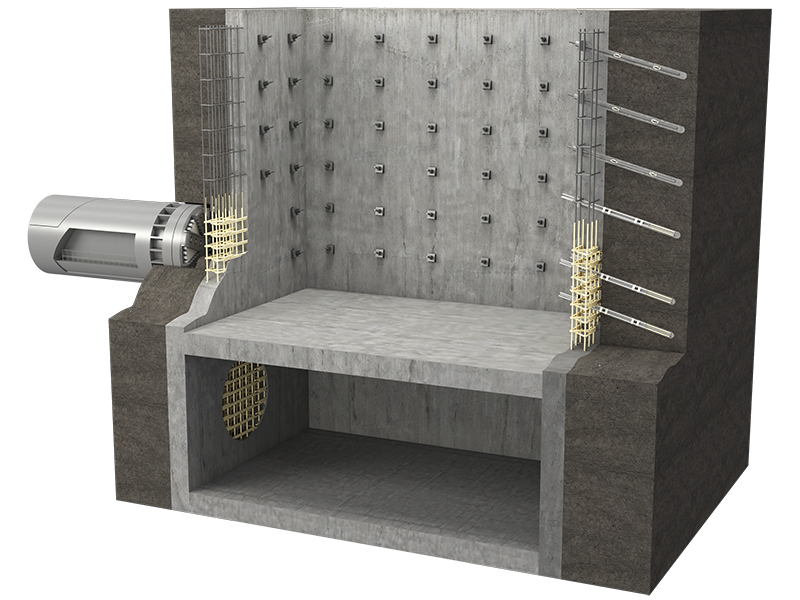

For the second phase, Dextra supplied 1,210 rock bolts for stabilising the tunnel excavations and 8 GFRP Soft-Eyes for TBM breakthrough.

On completion of phase 2, anticipated to be in 2022, the NEWater factory at the Tuas WRP will contribute to 55% of the total water demand of Singapore.

In addition, the Tuas WRP will treat 800,000 cubic meters of used water per day, making it the largest membrane bioreactor facility in the world.